Composite flame-retardant filler preparation method and product thereof

A composite flame retardant and product technology, which is applied in fibrous fillers, chemical instruments and methods, dyeing low molecular weight organic compounds, etc. and other problems to achieve the effect of improving comprehensive mechanical properties and surface gloss, improving flame retardancy and improving surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

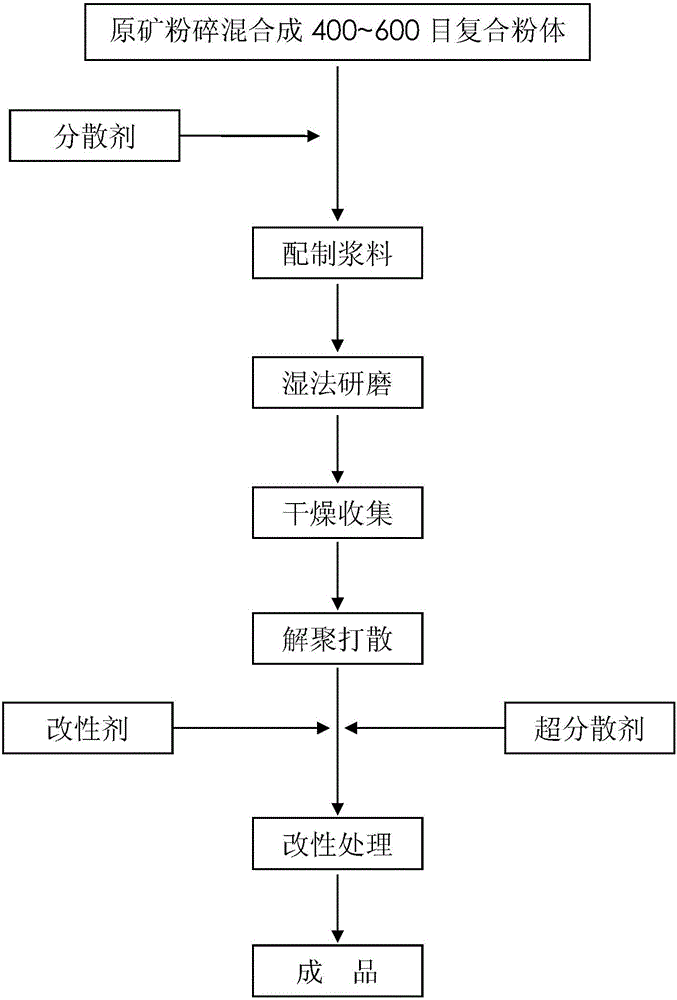

Method used

Image

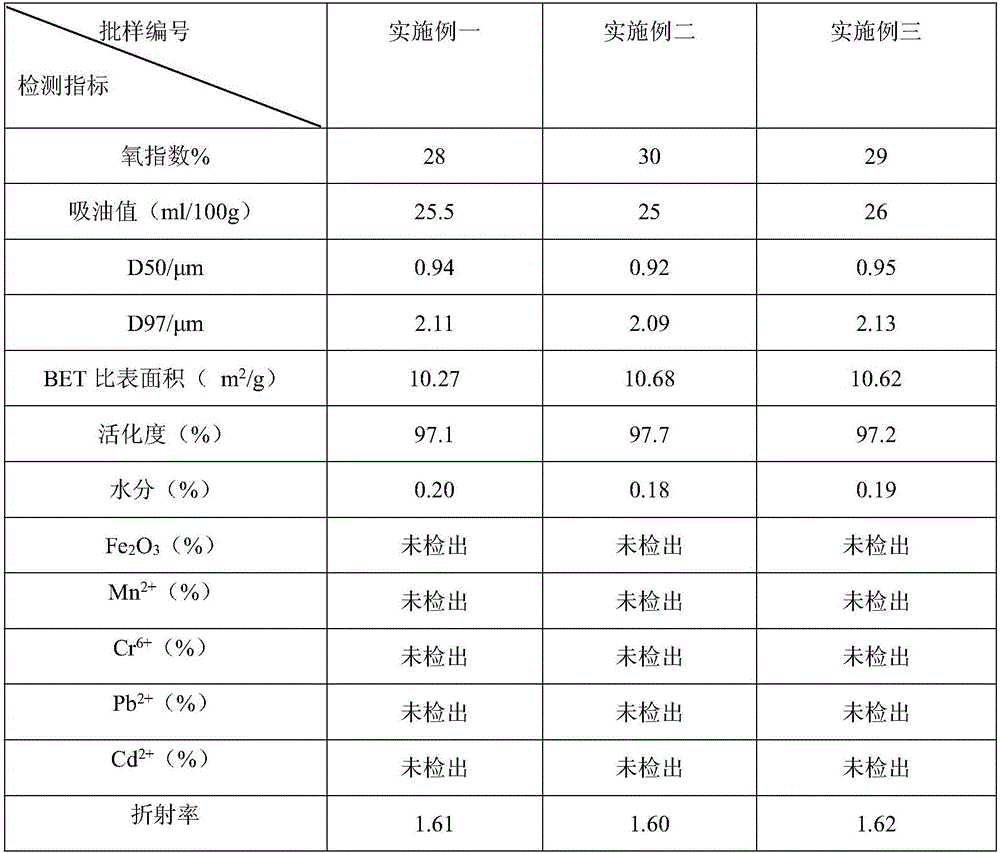

Examples

Embodiment 1

[0026] A preparation method for a composite flame retardant filler, comprising the following steps:

[0027] The raw ore of barium sulfate is roughly crushed, cleaned, and crushed once to obtain a raw ore with a diameter of 5-10cm, which is then put into the silo for secondary crushing to obtain a material with a diameter of 5-10mm, and finally dried by a ring roller mill. Method grinding, obtain 600 purpose barium sulfate powder;

[0028] Add 600-mesh barium sulfate powder and magnesium chloride according to the mass ratio of 4:1 and add water to form a slurry with a solid content of 75%. During the preparation process, add lignosulfonate compound grinding aid, and then control the temperature of the slurry at 70- Constant temperature stirring wet grinding at 80°C, adding 4‰ sodium polyacrylate dispersant, 3‰ sodium polycarboxylate dispersant and calcium hydroxide equal to the molar number of magnesium chloride during the stirring process to prepare 6000 The purpose of compo...

Embodiment 2

[0031] A preparation method for a composite flame retardant filler, comprising the following steps:

[0032] The raw ore of barium sulfate is roughly crushed, cleaned, and crushed once to obtain a raw ore with a diameter of 5-10cm, which is then put into the silo for secondary crushing to obtain a material with a diameter of 5-10mm, and finally dried by a ring roller mill. method grinding, to obtain 700 mesh barium sulfate powder;

[0033] Mix 700 mesh barium sulfate powder and magnesium chloride with water at a mass ratio of 5:1 to form a slurry with a solid content of 70%. During the preparation process, add lignosulfonate compound grinding aid, and then control the temperature of the slurry at 70- Perform constant temperature stirring wet grinding at 80°C, add sodium polyacrylate dispersant with powder quality of 5‰, styrene-maleic anhydride copolymer dispersant with 4‰ and calcium hydroxide with the same molar number as magnesium chloride during the stirring process, Prep...

Embodiment 3

[0036] A preparation method for a composite flame retardant filler, comprising the following steps:

[0037] The raw ore of barium sulfate is roughly crushed, cleaned, and crushed once to obtain a raw ore with a diameter of 5-10cm, which is then put into the silo for secondary crushing to obtain a material with a diameter of 5-10mm, and finally dried by a ring roller mill. Method grinding, obtain 800 purpose barium sulfate powder;

[0038] Add water to 800 mesh barium sulfate powder and magnesium chloride at a mass ratio of 6:1 to make a slurry with a solid content of 80%. During the preparation process, add lignosulfonate compound grinding aid, and then control the temperature of the slurry at 70- Constant temperature stirring wet grinding between 80°C, adding powder quality 6‰ sodium polyacrylate dispersant, 5‰ sodium polycarboxylate dispersant, 6‰ styrene-maleic anhydride copolymer dispersant and Calcium hydroxide with the same number of moles as magnesium chloride to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com