High-light-resistance glass fiber reinforced PC plastic and preparation method thereof

A glass fiber and high-resistance technology, which is applied in the field of high-resistance glass fiber reinforced PC plastics and its preparation, can solve the problems of low shrinkage, good light-blocking performance, and high material strength, and achieve low shrinkage and good light-blocking performance , the effect of high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

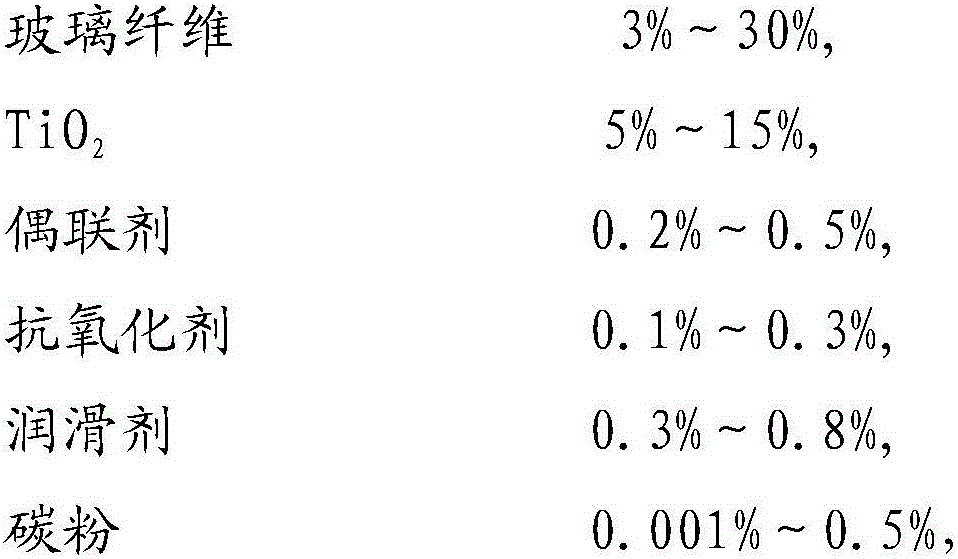

Method used

Image

Examples

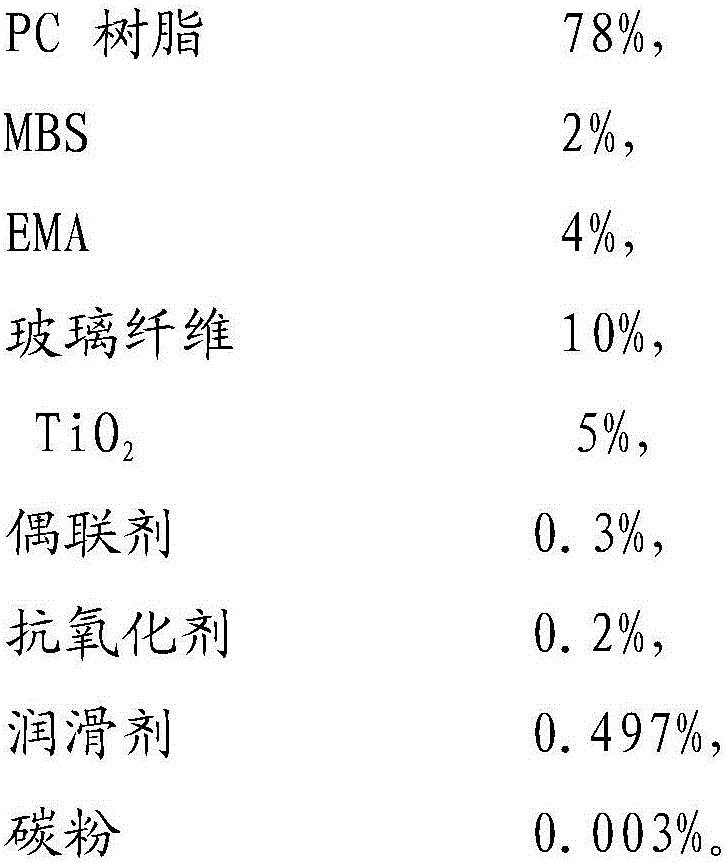

Embodiment 1

[0029] A high-resistance glass fiber reinforced PC plastic, comprising the following components by weight: PC resin 78%, MBS2%, EMA4%, glass fiber 10%, TiO 2 5%, coupling agent 0.3%, antioxidant 0.2%, lubricant 0.497%, carbon powder 0.003%.

[0030] Wherein, the PC resin is an aromatic polycarbonate, the MBS methyl methacrylate (M), a terpolymer of butadiene (B) and styrene (S), and the EMA is ethylene-acrylic acid The PC toughening agent of methyl ester copolymer, the antioxidant is phosphite antioxidant 627A; the lubricant is simethicone; the coupling agent is a silane coupling agent.

[0031] The preparation method of described high resistance light glass fiber reinforced PC plastic, comprises the following steps:

[0032] Step 1: Weigh PC resin, MBS, EMA, TiO 2 , coupling agent, antioxidant, lubricant and carbon powder are added to the mixing drum;

[0033] Step 2: stirring in the mixing drum for 8 minutes to obtain the mixed material;

[0034] Step 3: Set the temperat...

Embodiment 2

[0036] A high-resistance glass fiber reinforced PC plastic, comprising the following components by weight: PC resin 88%, MBS1%, EMA 1%, glass fiber 3%, TiO 2 5.9%, coupling agent 0.5%, antioxidant 0.1%, lubricant 0.4%, carbon powder 0.1%.

[0037] Wherein, the PC resin is an aromatic polycarbonate, the MBS methyl methacrylate (M), a terpolymer of butadiene (B) and styrene (S), and the EMA is ethylene- The PC toughening agent of methyl acrylate copolymer, the antioxidant is phosphite antioxidant 168; the lubricant is fatty acid amide lubricant; the coupling agent is a silane coupling agent.

[0038] The preparation method of described high resistance light glass fiber reinforced PC plastic, comprises the following steps:

[0039] Step 1: Weigh PC resin, MBS, EMA, TiO 2 , coupling agent, antioxidant, lubricant and carbon powder are added to the mixing drum;

[0040] Step 2: Stir in the mixing drum for 5 minutes to obtain the mixed material;

[0041] Step 3: Set the temperat...

Embodiment 3

[0043] A high-resistance glass fiber reinforced PC plastic, comprising the following components by weight: PC resin 68%, MBS2%, EMA 2%, glass fiber 17.4%, TiO 2 10%, coupling agent 0.4%, antioxidant 0.2%, lubricant 0.8%, carbon powder 0.2%.

[0044] Wherein, the PC resin is an aromatic polycarbonate, the MBS methyl methacrylate (M), a terpolymer of butadiene (B) and styrene (S), and the EMA is ethylene-acrylic acid The PC toughening agent of methyl ester copolymer, the antioxidant is phenolic antioxidant 1010; the lubricant is fatty acid amide lubricant; the coupling agent is a silane coupling agent.

[0045] The preparation method of described high resistance light glass fiber reinforced PC plastic, comprises the following steps:

[0046] Step 1: Weigh PC resin, MBS, EMA, TiO 2 , coupling agent, antioxidant, lubricant and carbon powder are added to the mixing drum;

[0047] Step 2: stirring in the mixing drum for 10 minutes to obtain the mixed material;

[0048] Step 3: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com