Method for preparing hydroxy terminated high-boiling silicone oil through low-temperature continuous hydrolysis technology

A hydroxyl-terminated, high-boiling silicone oil technology, which is applied in the field of silicone production, can solve the problems of easy emulsification of high-boiling silicone oil, easy product return to acid, alcohol-containing waste acid, and inability to properly handle waste neutralizer flux, etc. No three wastes discharge, stable product quality, avoid excessive cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

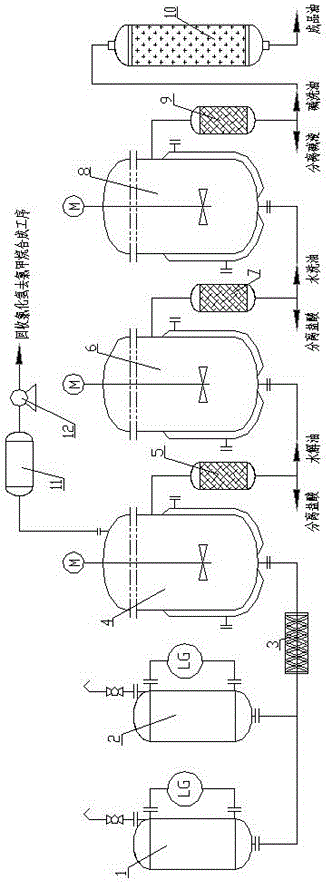

Image

Examples

Embodiment 1

[0034] A method for preparing hydroxyl-terminated high-boiling silicone oil by a low-temperature continuous hydrolysis process, the process steps are as follows:

[0035] ①Pretreatment of high boilers: Use a rectification device to rectify the by-product high-boiling chlorosilane mixtures (substances with a boiling point greater than 70.5°C under standard conditions) in the process of direct synthesis of methyl chlorosilanes, and collect them under standard conditions The fraction with a boiling range between 70.5°C and 160°C is used in the hydrolysis process to prepare hydroxyl-terminated high-boiling silicone oil.

[0036] ②Preparation of aqueous solution for hydrolysis: prepare the hydrolysis aid ferric chloride and production water to prepare an aqueous solution for hydrolysis with a catalyst mass concentration of 0.5%.

[0037] ③Hydrolysis: The methyl chlorosilane high boiler with a boiling range of 70.5℃~160℃ and the aqueous solution for hydrolysis are continuously pumpe...

Embodiment 2

[0043] A method for preparing hydroxyl-terminated high-boiling silicone oil by a low-temperature continuous hydrolysis process, the process steps are as follows:

[0044] ①Pretreatment of high boilers: Use a rectification device to rectify the by-product high-boiling chlorosilane mixtures (substances with a boiling point greater than 70.5°C under standard conditions) in the process of direct synthesis of methyl chlorosilanes, and collect them under standard conditions The fraction with a boiling range between 70.5°C and 140°C is used in the hydrolysis process to prepare hydroxyl-terminated high-boiling silicone oil.

[0045] ②Preparation of aqueous solution for hydrolysis: The hydrolysis aid sodium trifluoromethanesulfonate and hydrolysis acid are prepared to prepare an aqueous solution for hydrolysis with a mass concentration of catalyst of 1%.

[0046] ③Hydrolysis: The methyl chlorosilane high boiler with a boiling range of 70.5℃~140℃ and the aqueous solution for hydrolysis ...

Embodiment 3

[0052] A method for preparing hydroxyl-terminated high-boiling silicone oil by a low-temperature continuous hydrolysis process, the process steps are as follows:

[0053] ①Pretreatment of high boilers: Use a rectification device to rectify the by-product high-boiling chlorosilane mixtures (substances with a boiling point greater than 70.5°C under standard conditions) in the process of direct synthesis of methyl chlorosilanes, and collect them under standard conditions The fraction with a boiling range between 70.5°C and 140°C is used in the hydrolysis process to prepare hydroxyl-terminated high-boiling silicone oil.

[0054] ②Preparation of aqueous solution for hydrolysis: The hydrolysis aid sodium trifluoromethanesulfonate and hydrolysis acid are prepared to prepare an aqueous solution for hydrolysis with a mass concentration of catalyst of 1%.

[0055] ③Hydrolysis: The methyl chlorosilane high boiler with a boiling range of 70.5℃~140℃ and the aqueous solution for hydrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com