Broad-spectrum solid phase extracting filler and its application

A broad-spectrum, extraction technology, applied in the field of broad-spectrum solid phase extraction packing, can solve the problems of increased experimental intensity and cost, huge differences in properties, and a single adsorbent covers multiple types of compounds, achieving low price, simple preparation method, good quality and so on. The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A broad-spectrum solid-phase extraction filler, its synthesis method comprises the following steps: 1-vinylimidazole, divinylbenzene, azobisisobutyronitrile and acetonitrile are mixed, after ultrasonic treatment, remove oxygen under airtight condition at 50 React at ~70°C for 6-36 hours; pulverize and sieve the obtained product, sieve the product with a particle size of 40-60 μm, clean it, and dry it to obtain a broad-spectrum solid-phase extraction filler.

[0028] Preferably, the molar ratio of 1-vinylimidazole to divinylbenzene is 1:5˜5:1.

[0029] Preferably, the amount of azobisisobutyronitrile used is 1%-3% of the sum of the mass of 1-vinylimidazole and divinylbenzene.

[0030] Preferably, the molar volume ratio of 1-vinylimidazole to acetonitrile is (2-10) mmol: (5-15) mL.

[0031] Preferably, the ultrasonic treatment time is 15-30 minutes.

[0032] Preferably, the method for removing oxygen is filling with nitrogen or inert gas.

[0033] Preferably, the produ...

Embodiment 1

[0051] The synthetic method of embodiment 1 broad-spectrum solid-phase extraction filler

[0052] Dissolve 10 mmol of 1-vinylimidazole and 2 mmol of divinylbenzene in 5 mL of acetonitrile solution, add 30 mg of azobisisobutyronitrile, ultrasonically disperse for 20 min, fill with nitrogen and deoxygenate for 10 min, and seal. React under water conditions of 60°C for 24 hours to obtain a lumpy product, then grind the product, sieve, and sieve the product with a particle size of 40-60 μm. Then, the sieved polymer was ultrasonically cleaned with methanol solution for 5 times, each time for 30 minutes, to remove excess reactants, and dried at 60°C for 24 hours to obtain a broad-spectrum solid-phase extraction filler for future use.

[0053] The broad-spectrum solid-phase extraction filler that this embodiment prepares is figure 1 White powdery granules shown.

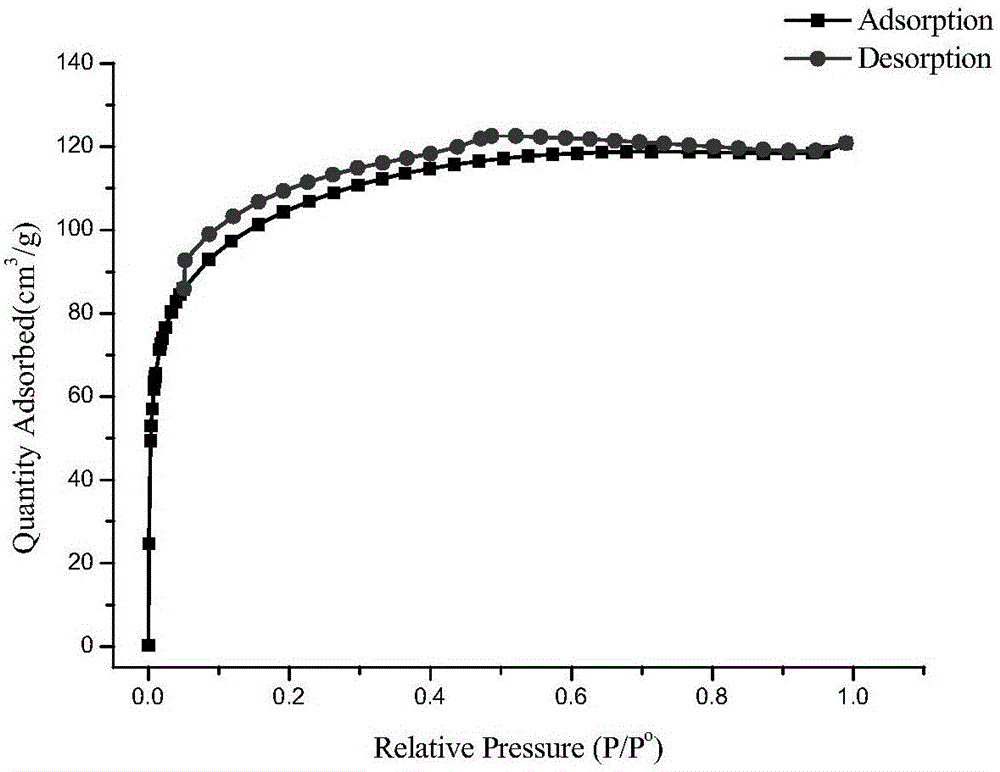

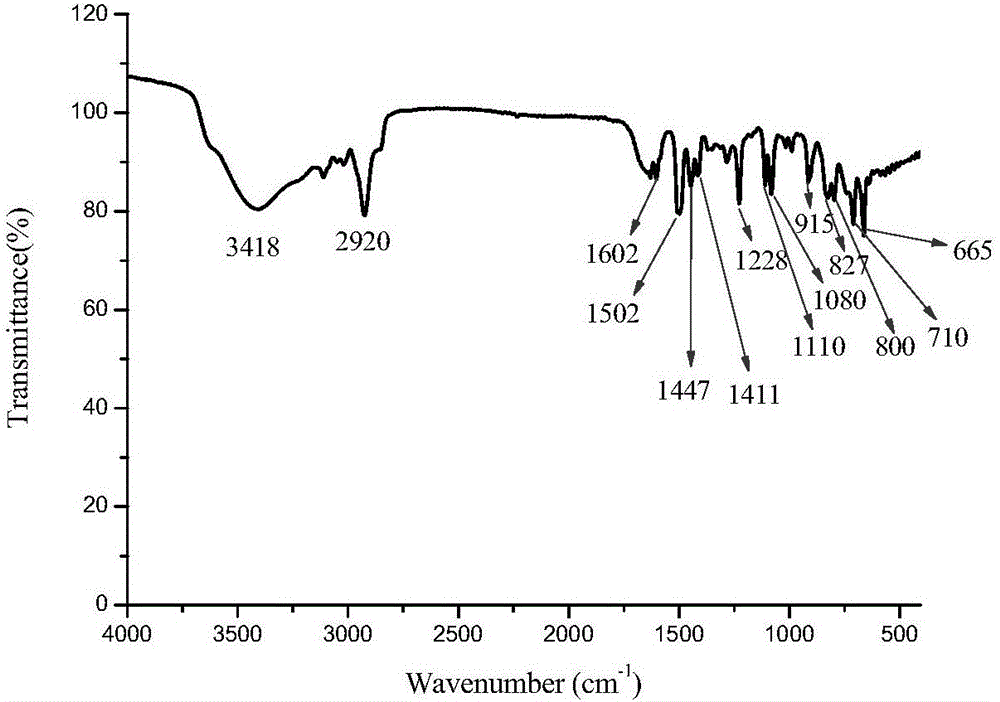

[0054] figure 2 Be the BET test isothermal adsorption-desorption curve of the broad-spectrum solid-phase extraction f...

Embodiment 2

[0057] The synthetic method of embodiment 2 broad-spectrum solid-phase extraction filler

[0058] Dissolve 10 mmol of 1-vinylimidazole and 2 mmol of divinylbenzene in 15 mL of acetonitrile solution, add 12 mg of azobisisobutyronitrile, ultrasonically disperse for 15 min, fill with nitrogen and deoxygenate for 10 min, and seal. React for 36 hours at 50°C in water to obtain a lumpy product, then grind the product, sieve, and sieve the product with a particle size of 40-60 μm. Then, the sieved polymer was ultrasonically cleaned with methanol solution for 6 times, 20 minutes each time, to remove excess reactants, and dried at 55°C for 20 hours to obtain a broad-spectrum solid-phase extraction filler for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com