Ternary rare earth complex and application of complex in preparing high-strength hybrid luminous hydrogel

A technology of rare earth complexes and complexes, which is applied to compounds containing elements of group 3/13 of the periodic table, luminescent materials, organic compounds of group 3/13 without C-metal bonds, etc. problem, to achieve the effect of good mechanical strength, good self-healing performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Using Eu(TTA) 3 (408mg, 0.5mmol) with Tpy-mim 2 (415mg, 0.5mmol) was dissolved in 10mL of methanol, heated to 80°C and kept stirring for 6 hours, after cooling to room temperature, 100mL of ether was added to make the precipitation fully, and a white precipitate was obtained. The resulting precipitate was collected by centrifugation, washed with three times the volume of precipitated ether, and dried in vacuo to obtain Eu(TTA) 3 Tpy-mim 2 powder.

[0033] (2) Disperse 150 mg of laponite LAPONITE XLG nanoclay in 3.5 mL of deionized water, and stir at room temperature for 10 minutes. 4.5 mg of ASAP was dissolved in 0.5 mL of deionized water and added to the nanoclay dispersion. After 10 minutes, add Eu(TTA) 3 Tpy-mim 2 Aqueous solution (containing 4.0mg Eu(TTA) 3 Tpy-mim 2 , the volume of the solution is 1.0 mL), and the stirring was continued for 3 minutes to obtain a luminescent hydrogel.

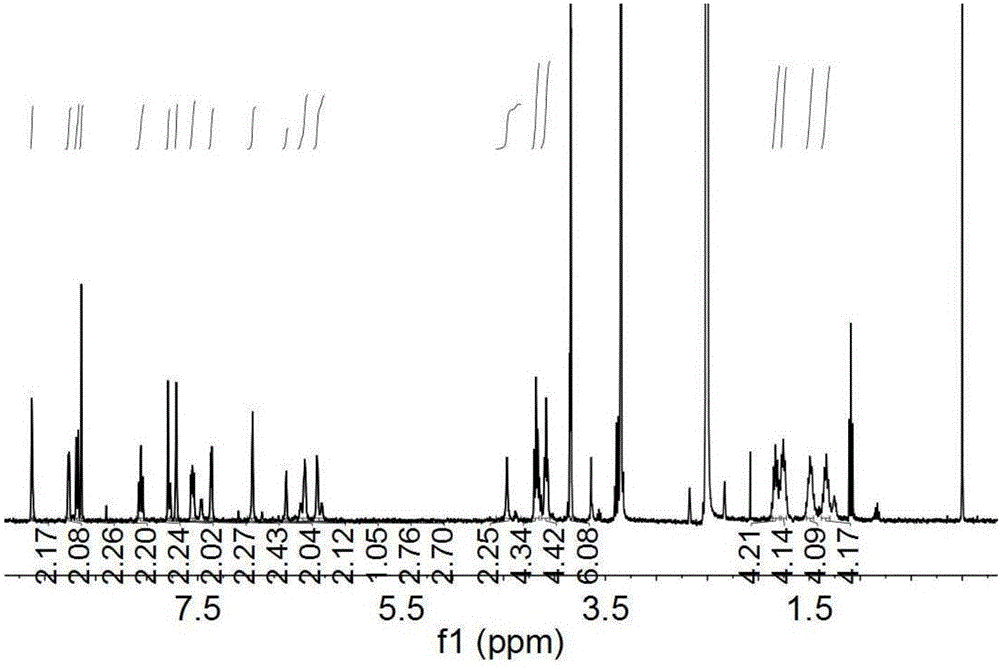

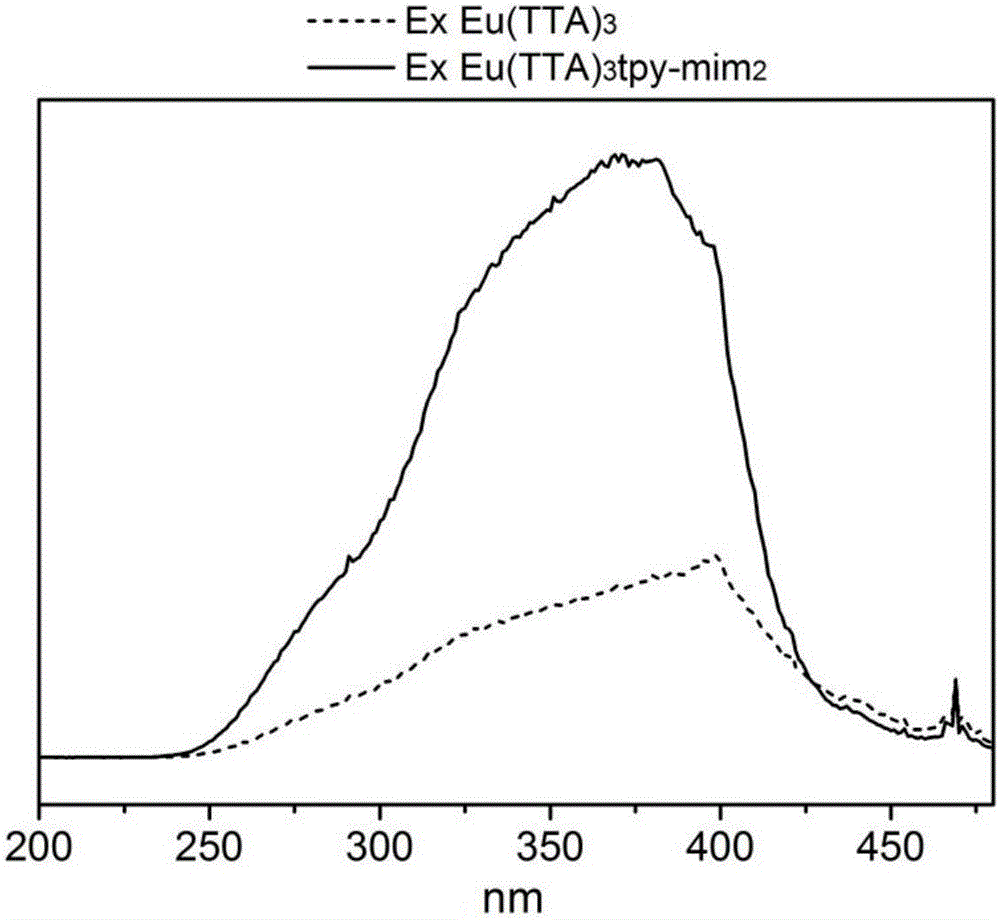

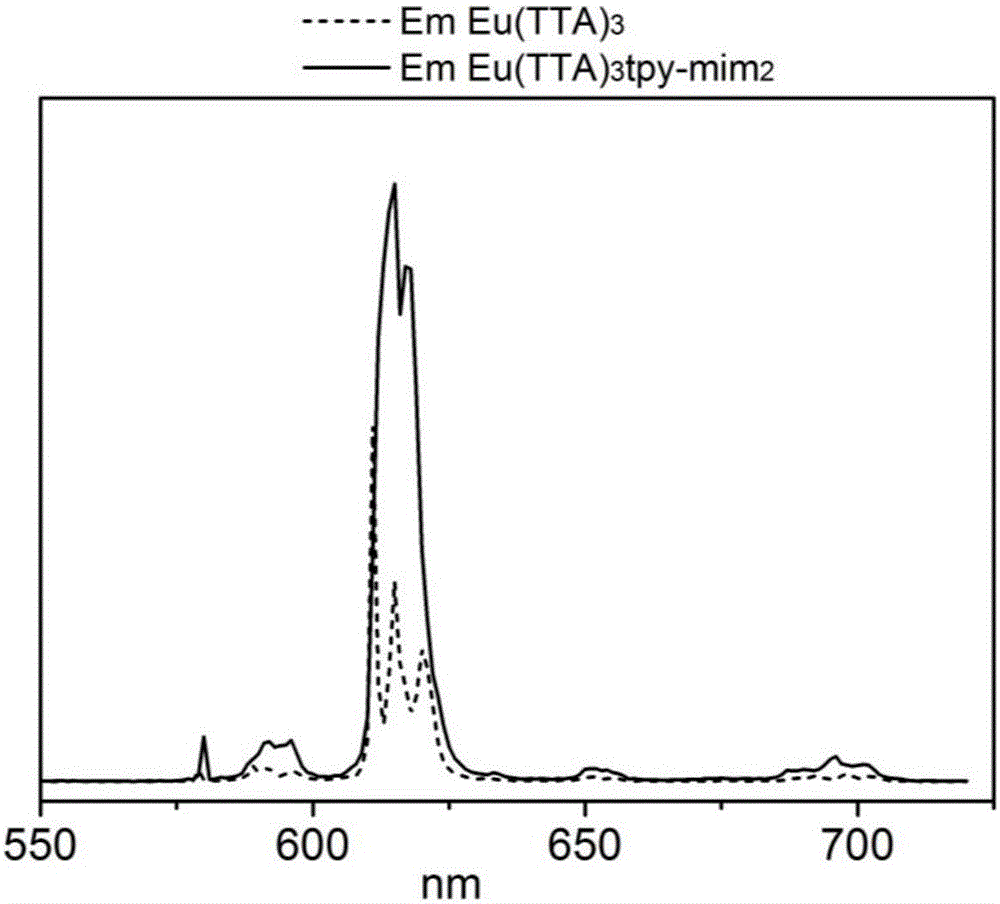

[0034] figure 1 for Eu(TTA) 3 Tpy-mim 2 of 1 H NMR nuclear mag...

Embodiment 2

[0039] Step (1) is the same as in Example 1, and the amount of laponite LAPONITE XLG nanoclay in step (2) is increased to 300mg. Experiments show that increasing the mass fraction of laponite LAPONITE XLG nanoclay can significantly increase the elastic modulus value of the obtained gel, and achieve the purpose of enhancing its mechanical strength.

Embodiment 3

[0041] 1) Using Yb(TTA) 3 (420mg, 0.5mmol) with Tpy-mim 2 (415mg, 0.5mmol) was dissolved in 10mL of methanol, heated to 80°C and kept stirring for 6 hours, after cooling to room temperature, 100mL of ether was added to make the precipitation fully, and a white precipitate was obtained. The resulting precipitate was collected by centrifugation, washed with three times the volume of precipitated ether, and dried in vacuo to obtain Yb(TTA) 3 Tpy-mim 2 .

[0042] (2) Disperse 150 mg of laponite LAPONITE XLG nanoclay in 3.5 mL of deionized water, and stir at room temperature for 10 minutes. 4.5 mg of ASAP was dissolved in 0.5 mL of deionized water and added to the nanoclay dispersion. After 10 minutes, add Yb(TTA) 3 Tpy-mim 2 Aqueous solution (4.1mg, 1.0mL), continue to stir for 3 minutes to obtain a luminescent hydrogel. Compared with Example 1, its mechanical strength has no obvious change. and Yb(TTA) 3 Tpy-mim 2 Gel with Yb(TTA) 3 Compared with ASAP predispersed lapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com