Oily sludgestepwisecontinuous pyrolysis and energy supplying integration method and device

The technology of an oil-water separation device and a cracking device is applied in the field of step-by-step continuous pyrolysis and energy supply integration of oily sludge, which can solve the problems of no good utilization of residual oil and low energy utilization rate of the solution, so as to solve the problem of energy recycling. The effect of utilization problems, improving energy utilization, and reducing pyrolysis costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An integrated method for step-by-step continuous pyrolysis and energy supply of oily sludge, comprising the following process:

[0040] Step 1: Primary cracking

[0041] The oily sludge enters the first-stage cracking device from the oily sludge feed port, and is indirectly heated by gas, and the material is transported to the discharge end of the first-stage cracking device through the built-in screw conveyor, and the pyrolysis oil gas produced is produced by the first-stage pyrolysis device. The pyrolysis gas outlet of the cracking unit is connected to the pyrolysis gas inlet of the secondary cracking unit;

[0042] Step 2: Secondary cracking

[0043] The pyrolysis oil and gas produced by primary cracking enters the secondary cracking device for cracking; the pyrolysis oil and gas entering the secondary cracking device mainly contains: tar, water vapor, hydrogen, carbon monoxide, small molecular alkanes, olefins and large molecular oil and gas, etc. Hydrogen compoun...

Embodiment 2

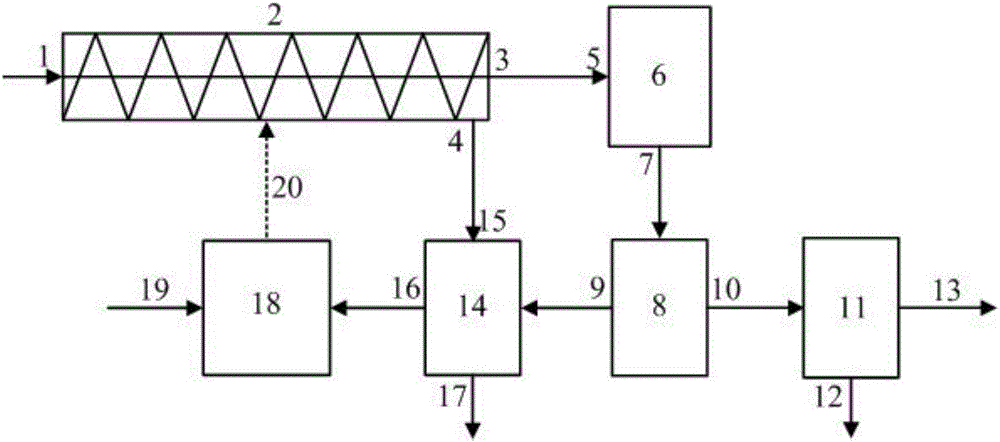

[0049] An integrated step-by-step continuous pyrolysis and energy supply device for oily sludge, including a primary cracking device 2, a secondary cracking device 6, a spray tower 8, an oil-water separation device 11, a gas drying device 14, and a combustion device 18; The first-stage cracking device 2 has a built-in oily sludge screw conveying structure. The pyrolysis gas outlet 3 of the first-stage cracking device is connected to the pyrolysis gas inlet 5 of the second-stage cracking device. The slag outlet 4 of the first-stage cracking device is connected to the slag inlet 15 of the gas drying device. The cracking gas outlet 7 of the stage cracking device is connected to the spray tower 8, the liquid phase outlet 10 of the spray tower is connected to the oil-water separation device 11, the gas phase outlet 9 of the spray tower is connected to the gas drying device 14, and the non-condensable gas outlet 16 of the gas drying device is connected to the The combustion device 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com