A kind of nickel boride powder with network structure and preparation method thereof

A network structure, nickel boride technology, applied in the direction of boron/boride, metal boride, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix micron-sized metal nickel powder and amorphous boron powder (molar ratio 3:1) with 10 times the mass of sodium chloride / potassium chloride (molar ratio 1:1) and put them into a corundum crucible. Heated to 1000°C under the protection of argon, kept warm for 1 hour, and cooled naturally, then soaked the product in 1.0mol / L hydrochloric acid for 2 hours, filtered, washed with water and ethanol for several times, and dried to obtain Ni with a network structure. 3 B powder.

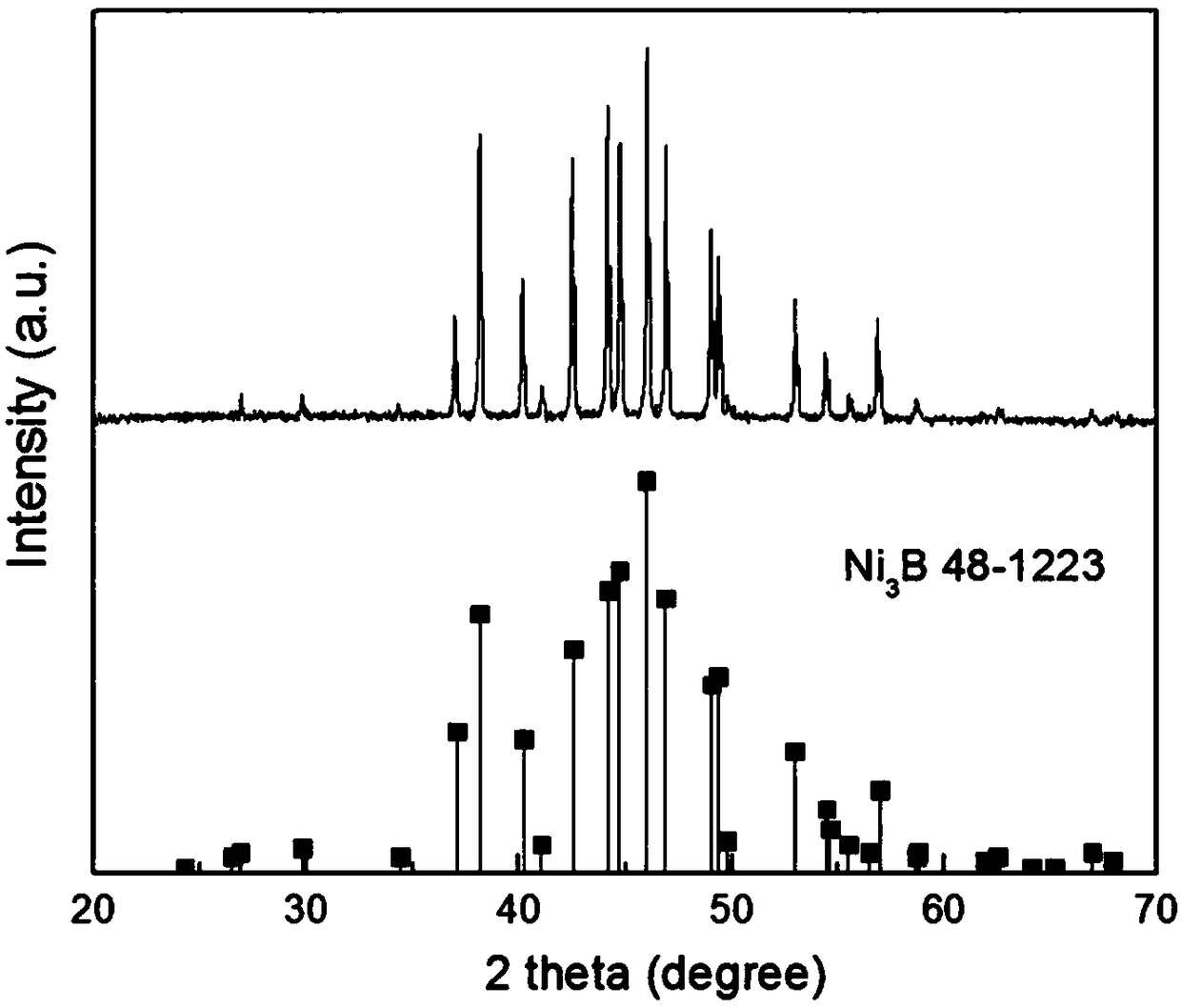

[0021] figure 1 Prepared Ni for this embodiment 3 The XRD spectrum of B powder body, as can be seen, the powder body prepared in this embodiment is crystalline Ni 3 B, no other impurity phases. figure 2 Prepared Ni for this embodiment 3 The SEM photo of powder B shows that the powder has a network structure, and the diameter of the network wire is about 20nm.

Embodiment 2

[0023] Mix micron-sized metal nickel powder and amorphous boron powder (molar ratio is 4:1) with 5 times the mass of sodium chloride powder and put it into a corundum crucible, heat it to 1100°C under the protection of argon, and keep it warm for 1h After cooling naturally, the product was soaked in 2.0mol / L hydrochloric acid for 4 hours, filtered, washed with water and ethanol for several times, and dried to obtain Ni 3 B powder.

Embodiment 3

[0025] Mix micron-sized metal nickel powder and amorphous boron powder (molar ratio 4.5:1) with 5 times the mass of sodium chloride powder, put them into a corundum crucible, heat to 1100°C under the protection of argon, and keep it warm for 1h After cooling naturally, the product was soaked in 3.0mol / L hydrochloric acid for 5 hours, filtered, washed with water and ethanol several times, and dried to obtain Ni 3 B powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com