A kind of flaky porous cob powder and preparation method thereof

A powder and flake technology, which is applied in the field of CoB powder preparation, can solve the problems that the reaction process is difficult to control and the powder with special morphology cannot be prepared.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix micron-sized metal cobalt powder and amorphous boron powder (molar ratio 1:2) with 10 times the mass of sodium chloride / potassium chloride powder (molar ratio 1:1) and put them into a corundum crucible. Heating to 1000°C under the protection of argon, keeping it warm for 1h, cooling naturally, then soaking the product in water for 1h, filtering, washing with water and ethanol for several times, and drying to obtain flaky porous CoB powder.

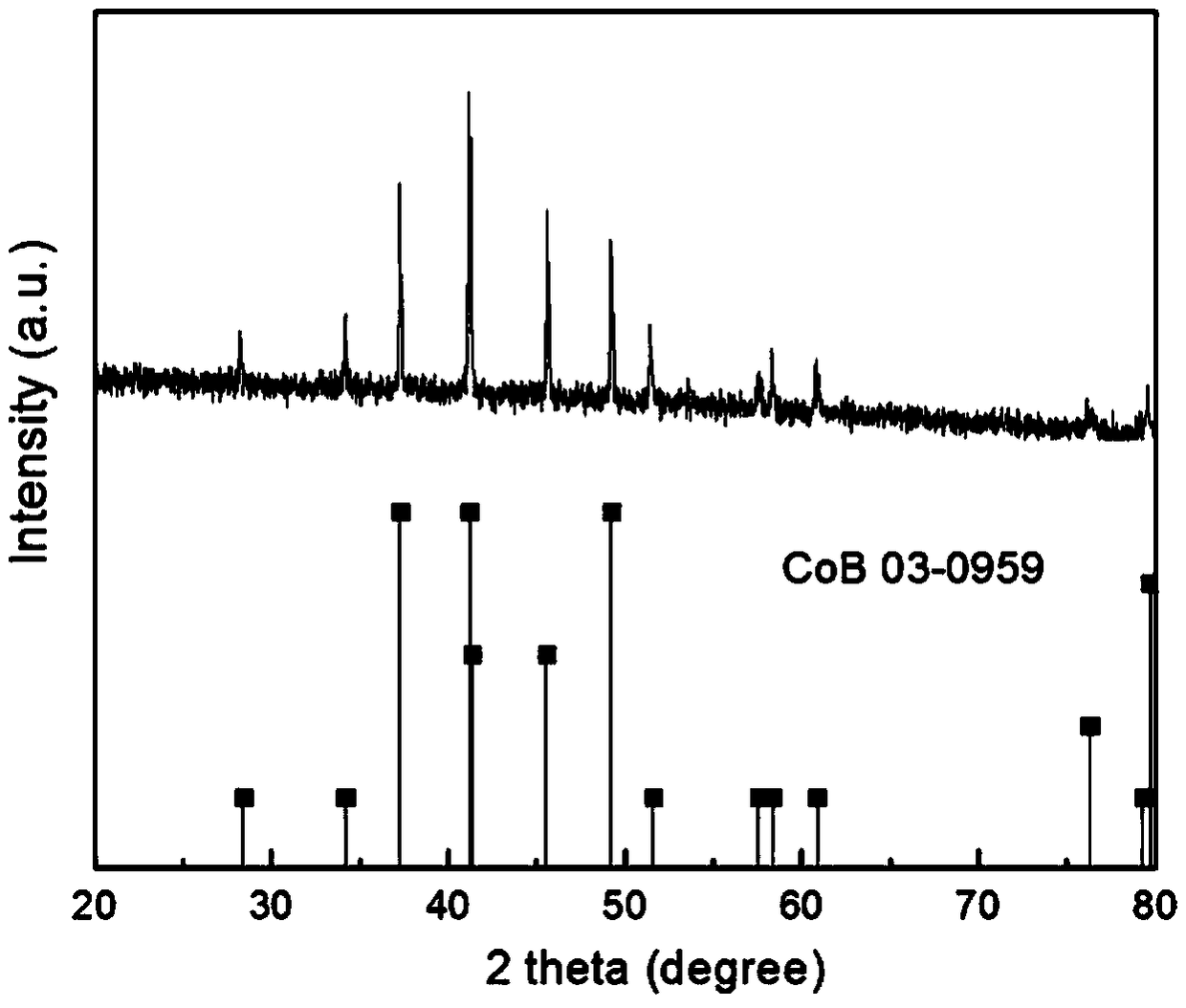

[0021] figure 1 From the XRD spectrum of the CoB powder prepared in this example, it can be seen that the powder prepared in this example is crystalline CoB. figure 2 From the SEM photo of the CoB powder prepared for this example, it can be seen that the powder is composed of many nanosheets with a thickness of about 20nm and a planar size of about 200-300nm, and these nanosheets are interconnected to form an open porous structure.

Embodiment 2

[0023] Mix micron-sized metallic cobalt powder and amorphous boron powder (molar ratio: 1:1.5) with 5 times the mass of sodium chloride powder, put them into a corundum crucible, heat to 1000°C under the protection of argon, and keep it warm for 1h After cooling naturally, the product was soaked in water for 1 h, filtered, washed with water and ethanol for several times, and dried to obtain a flaky porous CoB powder.

Embodiment 3

[0025] Mix micron-sized metallic cobalt powder and amorphous boron powder (molar ratio 1:1.2) with 5 times the mass of sodium chloride powder evenly, put it into a corundum crucible, heat to 1100°C under the protection of argon, and keep it warm for 1h After cooling naturally, the product was soaked in water for 2 hours, filtered, washed with water and ethanol for several times, and dried to obtain flaky porous CoB powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com