Calcium carbide cooling preforming mechanism

A preforming and calcium carbide technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of difficult control of the cooling process, condensation of small and large pieces of calcium carbide, etc., to facilitate continuous production, improve production efficiency, and facilitate molding control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

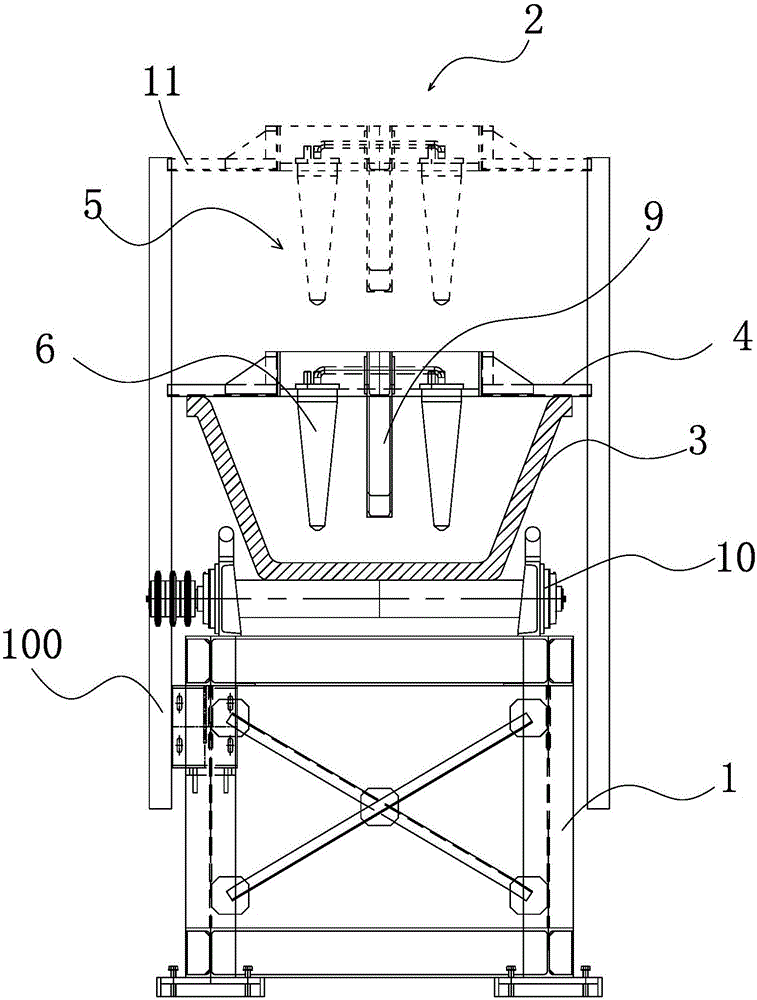

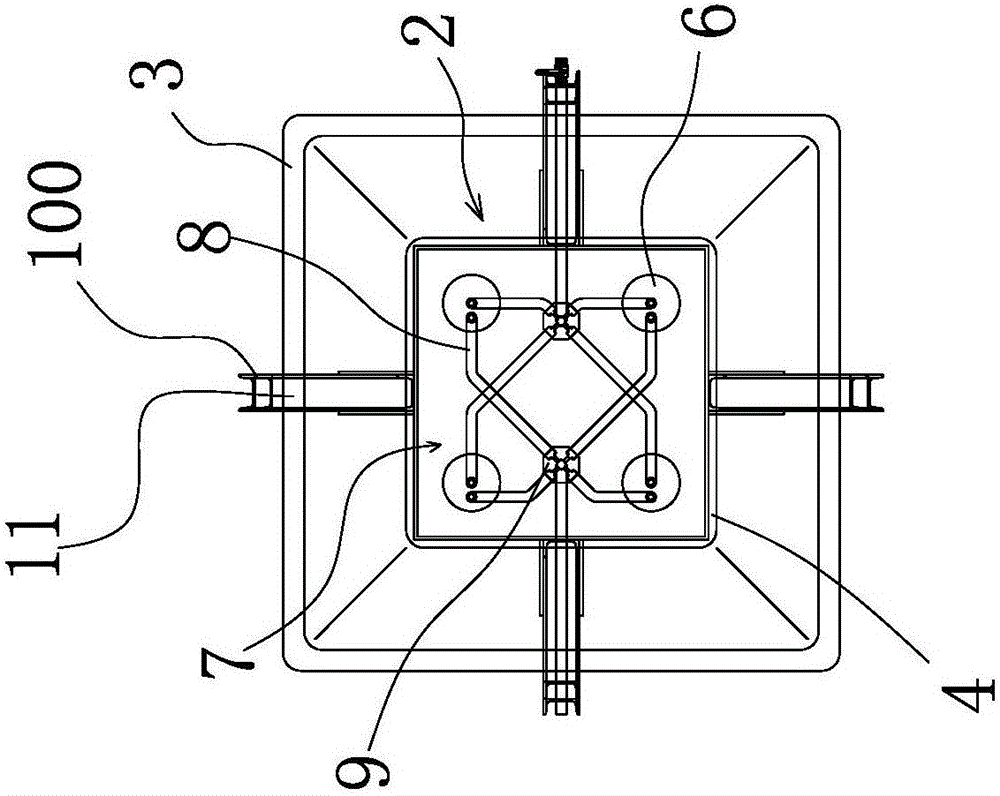

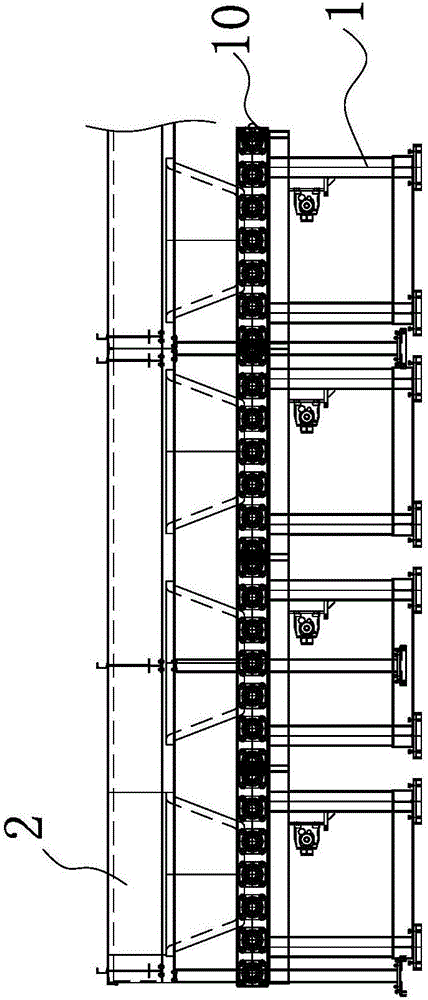

[0025] Such as figure 1 with figure 2 As shown, a calcium carbide cooling preforming mechanism includes a frame 1, and the frame 1 is provided with a preforming mechanism 2 that can be lifted along the vertical direction. When the preforming mechanism 2 has a molten When the calcium carbide hopper 3 is used, the preforming mechanism 2 can be inserted into the calcium carbide in the hopper 3 when it descends, and can be pulled out from the calcium carbide in the hopper 3 when the preforming mechanism 2 rises, so that the calcium carbide in the hopper 3 can form The shape of the preforming mechanism 2.

[0026] In this embodiment, the preforming mechanism 2 can be in various shapes. When the calcium carbide is in a molten state, it is inserted into the calcium carbide and placed for several minutes. The specific placement time is determined according to the process. After the calcium carbide is slightly cooled, it will transform from a molten state to a solid state. At this t...

Embodiment 2

[0031] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 with figure 2 As shown, the preforming assembly 5 includes at least one preforming column 6, the length of the preforming column 6 matches the depth of the hopper 3, and the cross-sectional area of the preforming column 6 gradually increases from the bottom to the top. The cross-section of the preformed column 6 can be polygonal, circular or elliptical, etc. As a preferred solution, the outer wall of the preformed column 6 should have a smooth arc, which is easy to pull out from the calcium carbide.

[0032] The working principle of this embodiment is: the shape of the preformed column 6 is easy to insert into calcium carbide, which is convenient for insertion and extraction, and improves the stability of work. 3 causing damage.

Embodiment 3

[0034] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 1 with figure 2 As shown, the preforming assembly 5 includes several preforming columns 6 , the axis lines of the several preforming columns 6 are not on the same plane, and the length of the preforming columns 6 matches the depth of the hopper 3 . The cross-sectional area of the preformed column 6 gradually increases from the bottom to the top.

[0035] The preforming mechanism 2 is fixedly connected with a calcium carbide separating mechanism 7 that can separate the calcium carbide in the hopper 3 when the preforming mechanism 2 is inserted into the hopper 3. When the preforming mechanism 2 is pulled out from the hopper 3, the hopper 3 The calcium carbide in the form forms a shape corresponding to the calcium carbide separation mechanism 7, that is, the shape of the calcium carbide separation mechanism 7 is also retained in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com