A salted egg quantitative distribution device

A quantitative distribution and salted egg technology, which is applied in transportation, packaging, loading/unloading, etc., can solve the problems of no quantitative distribution of salted eggs, high labor costs, and high labor intensity, so as to save labor, reduce production costs, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

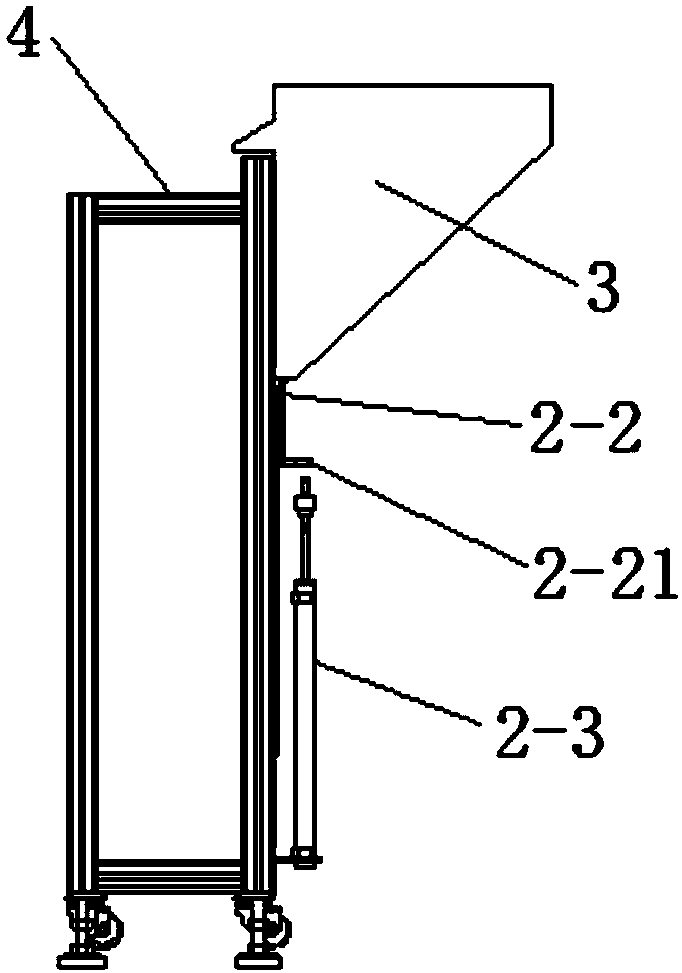

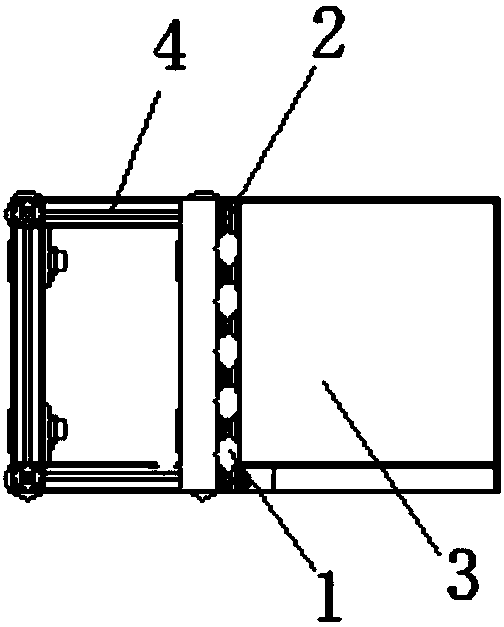

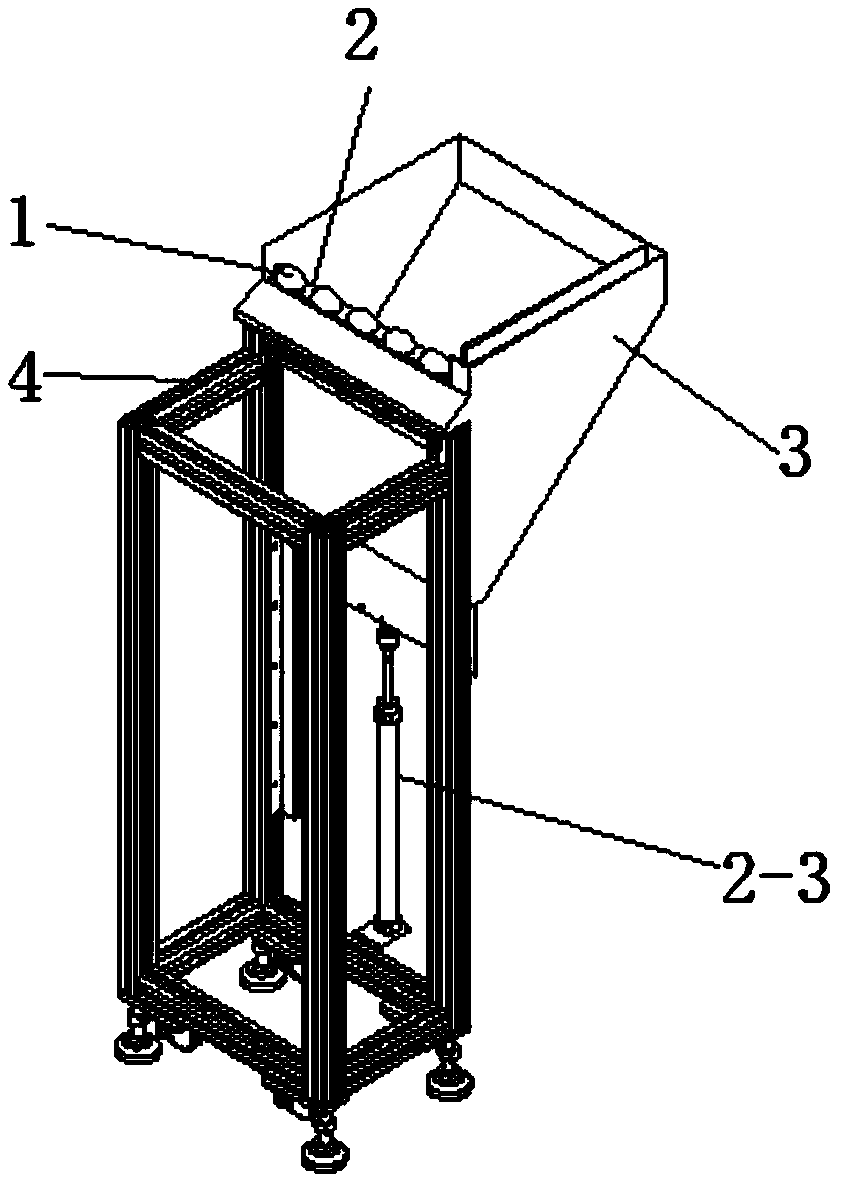

[0022] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

[0023] see Figure 1-Figure 10 , a salted egg quantitative distribution device of the present embodiment includes a frame 4, a salted egg box 3 for accommodating salted eggs 1, and a quantitative distribution mechanism 2, wherein the quantitative distribution mechanism 2 includes a moving plate 2-2 , the first drive mechanism 2-3 that drives the movement plate 2-2 to move up and down, the turning plate 2-1 that is connected to the upper end of the movement plate 2-2 and the second drive mechanism 2 that drives the turning plate 2-1 to turn over -4; the salted egg box 3 is fixed on one side of the frame 4, the moving plate 2-2 is arranged on the side near the frame 4 in the salted egg box 3, and the moving plate 2-2 is connected with the salted egg The distance between the side plates close to the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com