Automatic bar loading device

An automatic feeding and bar material technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of labor consumption, poor safety, low efficiency, etc., and achieve the effect of solving time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

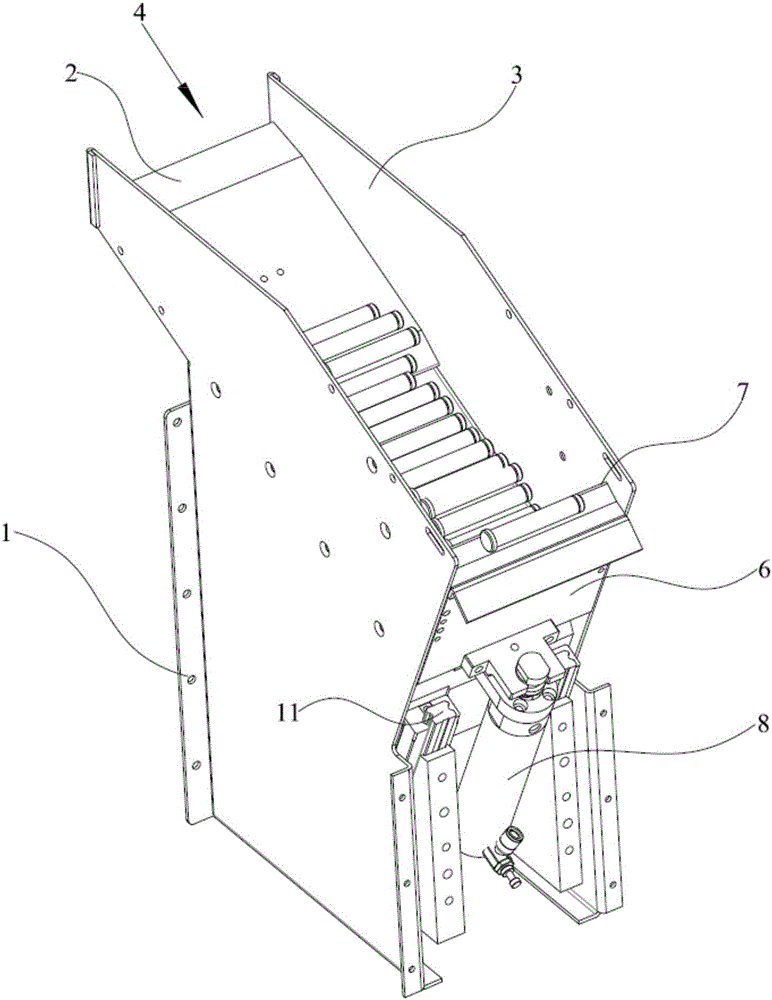

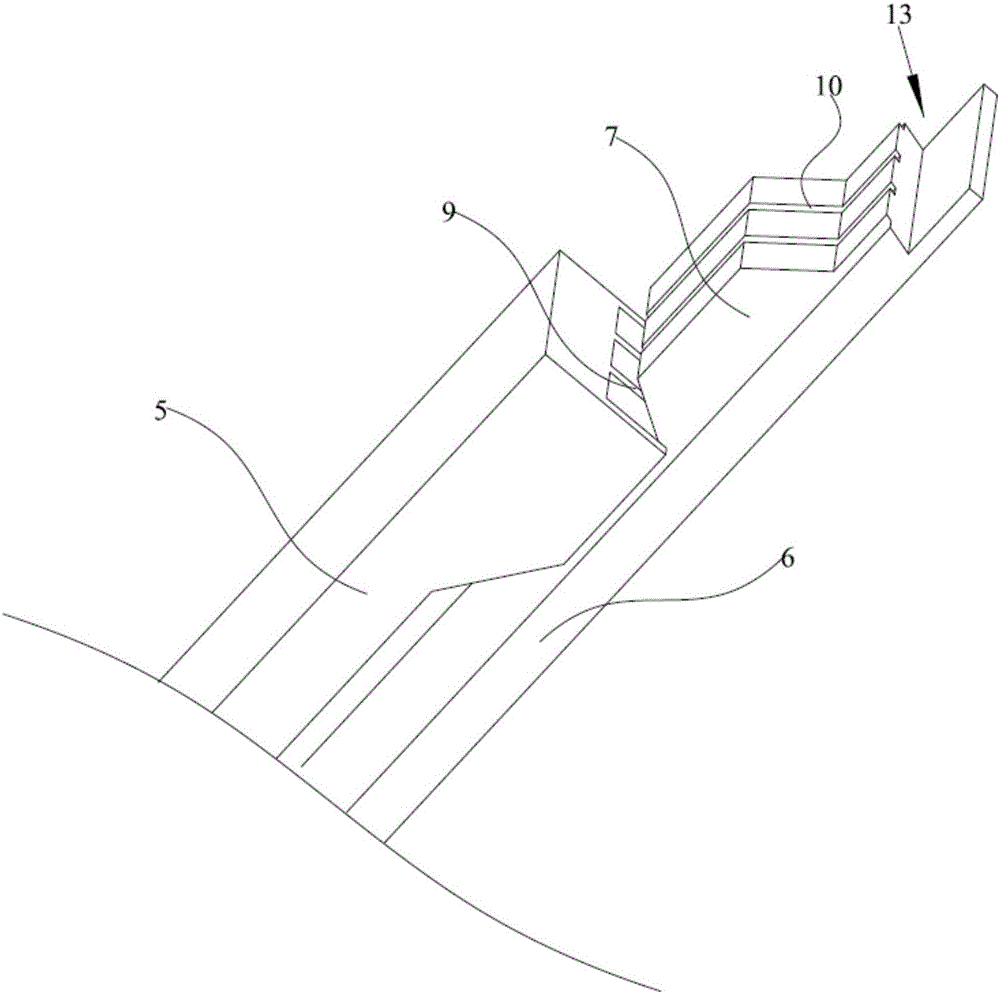

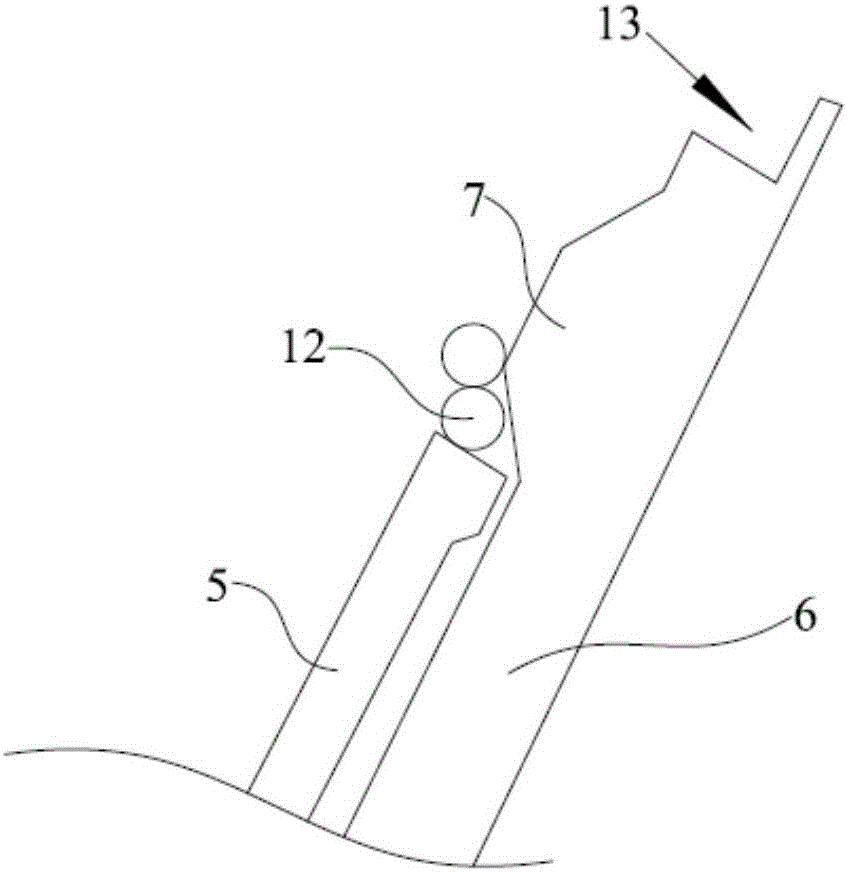

[0027] like Figure 1-Figure 5 As shown, this specific embodiment provides a kind of bar stock 12 automatic feeding device, comprises frame 1, is provided with feeding channel 4 on frame 1, and one end of feeding channel 4 is provided with pusher plate 5 obliquely, pusher plate 5 The side far away from the feeding channel 4 is provided with a material blocking plate 6 in parallel, and the pushing plate 5 is connected with a drive mechanism 8. Driven by the driving mechanism 8, the pushing plate 5 slides along the material blocking plate 6, and on the material blocking plate 6 A boss 7 is provided, and the boss 7 matches the top surface of the pushing plate 5, so that when the pushing plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com