Sliding intermediate supporting system for forced-cooling sliding column of spiral ship unloader

A technology of intermediate support and ship unloader, which is applied in loading/unloading, transportation, packaging, packaging, etc. It can solve the problems of lack of screw blades at the connecting shaft, large vibration and noise of the screw blades and is not suitable for empty vehicle operation, etc., to achieve extended The effect of long service life, small vibration and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

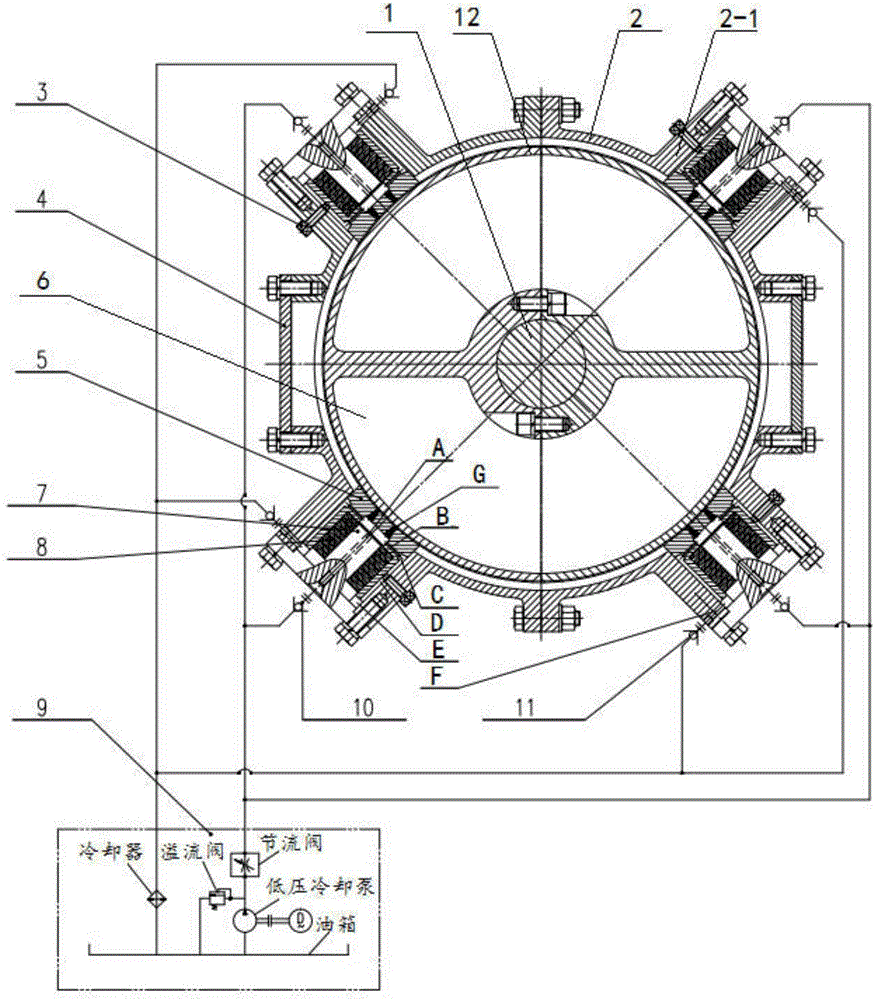

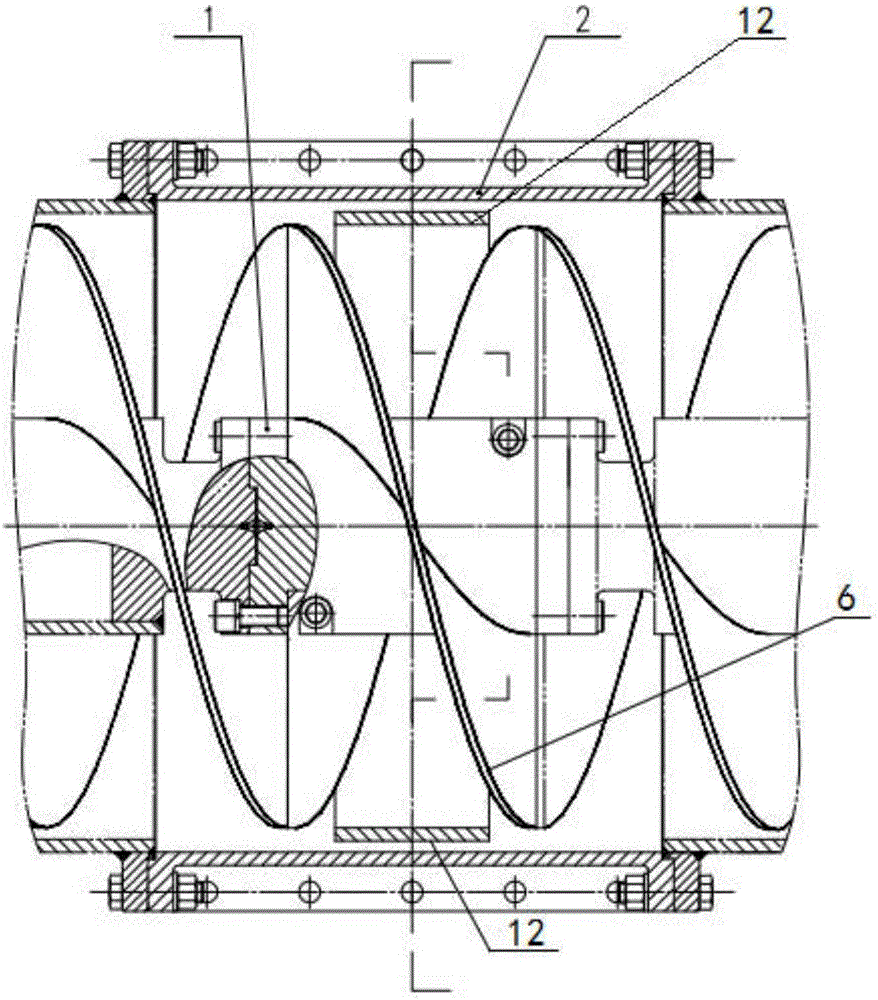

[0016] like figure 1 , 2 As shown in the figure, a sliding intermediate support system for forced cooling sliding columns of a screw ship unloader includes a connecting shaft 1, a supporting outer tube 2, a guide screw 3, a window cover plate 4, an empty stomach sliding column 5, a double-headed spiral leaf 6, and a spring core Shaft 7, Belleville spring 8, external heat exchange unit 9, the outer circumference of the blade of the double-headed spiral blade 6 is connected to two thin-walled semi-cylindrical tubes 12 through casting or welding, and the central axis of the double-headed spiral blade 6 is Two thick-walled semi-cylindrical tubes, two half-walled semi-cylindrical tubes are combined and fastened on the journal of the connecting shaft 1 to form a small section of a complete double-ended screw shaft, and two thin-walled semi-cylindrical tubes 12 on the outer periphery of the double-ended screw blade 6 are combined It is a complete cylindrical tube; the two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com