Preparation method of high-sound-absorption ultralight high-strength GMT composite board

A composite sheet and high-absorption technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of insufficient air infiltration, product design freedom and NVH performance backwardness, etc., to reduce the amount of materials , degree of freedom and NVH performance improvement, and the effect of mechanical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

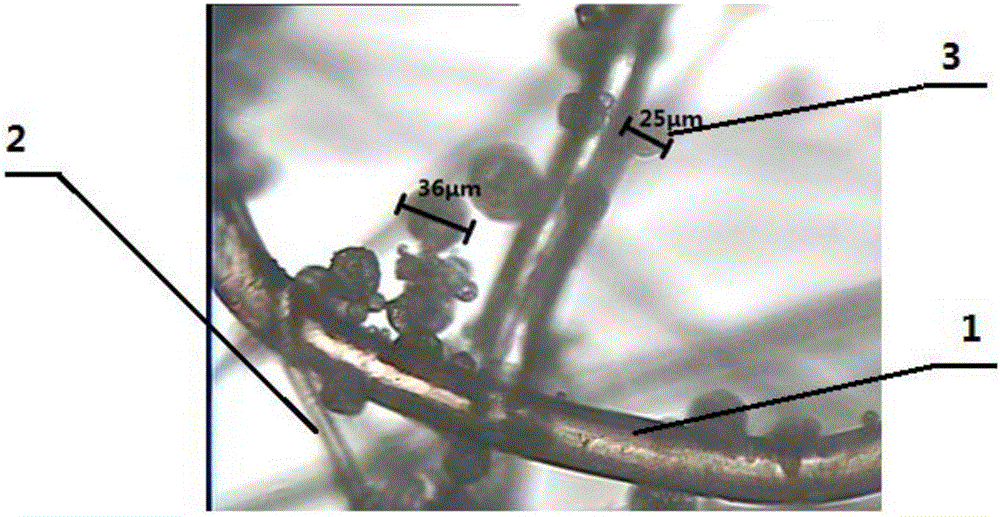

[0036] A high-sound-absorbing ultra-light and high-strength GMT composite sheet for preparing automobile bottom guards, which consists of thermoplastic polypropylene fibers as a bonding matrix, glass fibers as a reinforcing material, and the expansion of the sheet can be adjusted by changing the lattice point connection mode between the glass fibers Specific efficacy of microsphere foaming agent 3 composition, such as figure 1 As shown, and made into ultra-light and high-strength GMT composite sheet for automobile bottom guard plate by hot pressing, the surface density of the composite sheet is 1000g / m 2 . Its specific preparation method comprises the following steps:

[0037] (1) 60wt% thermoplastic polypropylene fibers and 40wt% glass fibers are uniformly mixed in proportion, and through carding, laying and needle punching, a blended composite fiber mat is obtained;

[0038] (2) The blended composite fiber felt is passed through the water-based mixture made of 3wt% water-s...

Embodiment 1

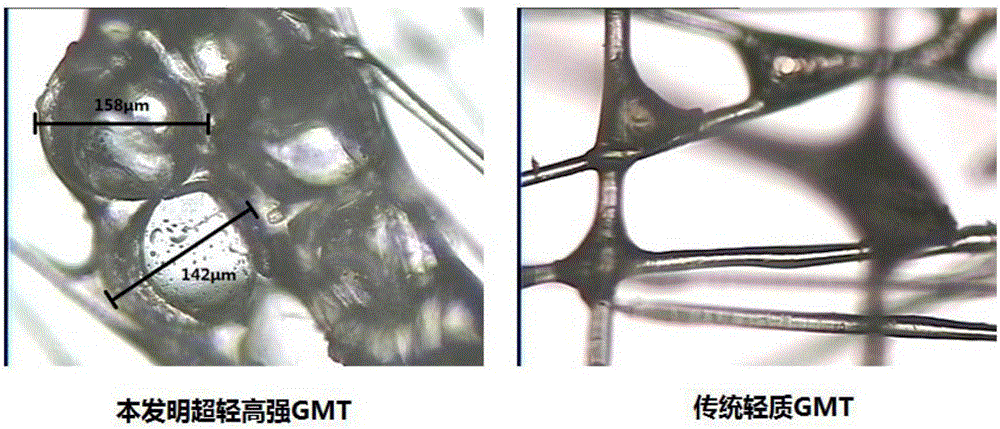

[0064] Example 1 Introduce microsphere foaming agent 3 inside the existing light-weight GMT composite board felt net. The introduction of microsphere foaming agent 3 makes the connection mode between glass fibers more diverse. In addition to traditional point connections, microspheres The foaming agent 3 binds the glass fibers around it as a connecting bridge, and the microsphere foaming agent 3 is connected to each other again, as figure 2 As shown, these diverse connection methods have fundamentally changed the internal felt network structure of the composite board, so the prepared bottom protection product has significantly improved mechanical properties compared with Comparative Example 1 at the same density, and compared with the traditional high-density GMT composite board. The mechanical properties of ratio 2 are equivalent, so that it can reduce the amount of its own materials and achieve the purpose of ultra-lightweight under the premise of ensuring the safety and str...

Embodiment 2

[0066] A high-sound-absorbing ultra-light and high-strength GMT composite sheet for preparing automotive roof components, which is composed of thermoplastic ES fiber as a bonding matrix, plant fiber as a reinforcing material, and the expansion ratio of the sheet can be adjusted by changing the connection mode between the two lattice points of the reinforcing fiber Composed of 3 effective microsphere foaming agents, and made into ultra-light and high-strength GMT composite sheets for automobile roofs by hot pressing, the surface density of the composite sheets is 600g / m 2 . Its specific preparation method comprises the following steps:

[0067] (1) 48wt% thermoplastic ES fiber and 52wt% plant fiber are mixed evenly in proportion, and the blended composite fiber mat is obtained through carding, laying and needle punching;

[0068] (2) The blended composite fiber felt is passed through a water-based mixture made of 8wt% water-soluble acrylate polymer, 5wt% aluminate coupling age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com