Variable-rigidity flexible drive joint

A joint and stiffness technology, which is applied in the field of variable stiffness and compliant drive joints, can solve problems such as human safety threats, achieve the effects of reducing accidental injuries, improving contact safety, and expanding applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

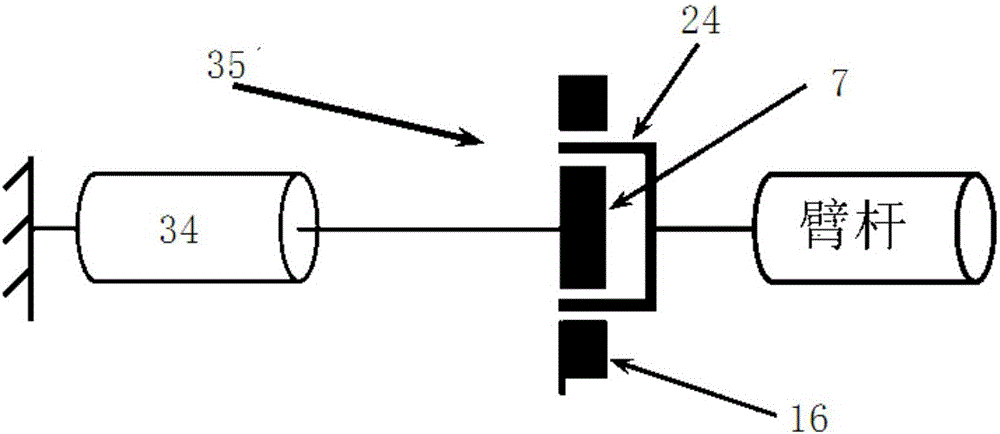

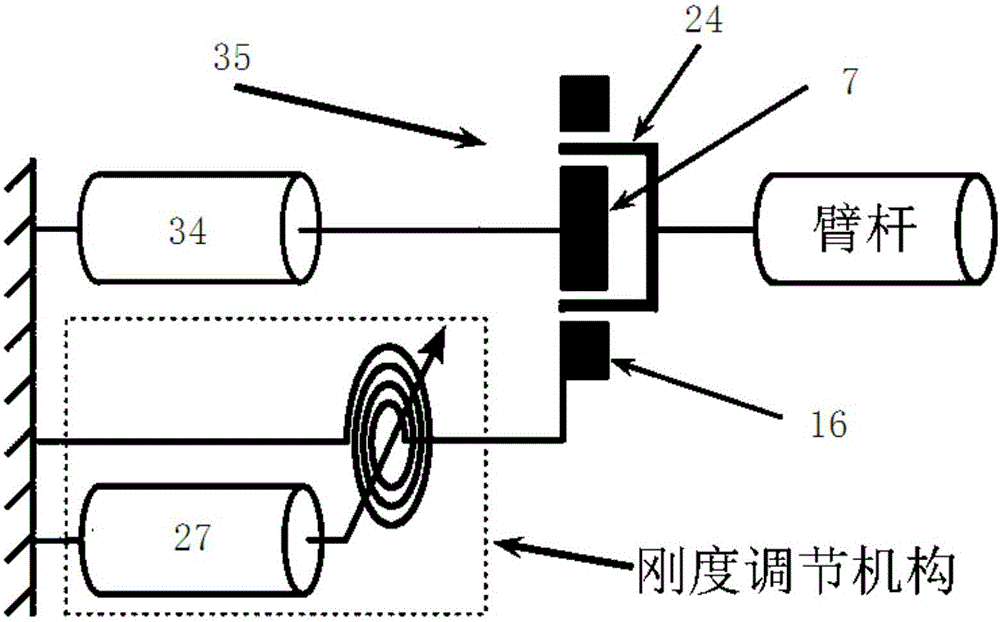

[0030] Stiffness adjustment motor 27 drives planetary reducer 4 to rotate, planetary reducer 4 drives small spur gear 5 to rotate synchronously through shaft hole, small spur gear 5 meshes with large spur gear 6, and large spur gear 6 is fixed to drive disc 7 by screws 8 , and rotate on the fixed shaft 25 through the bearing 33, wherein the fixed shaft 25 is fixed on the motor casing 2 by the screw 26. The outer ring of the drive disc 7 cooperates with the inner ring of the joint housing 3 through the bearing 19 . Have 4 chutes on the driving disc 7, and the profile curve of the chutes is a constant speed helix.

[0031] The rotation of the chute will drive the movement of the slider 21 through the bearing 22, the slider 21 is fixedly connected with the ball spline sleeve 12, the ball spline sleeve 12 is connected with the ball spline 13 through the screw 14, and the whole can be moved along the spline shaft 11. Linear sliding, one end of the spline shaft 11 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com