Novel polishing fixing jig for small and medium single liquid crystal display panels

A liquid crystal panel and fixed fixture technology, which is applied to surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as high fragmentation rate, increased factory operating costs, and fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

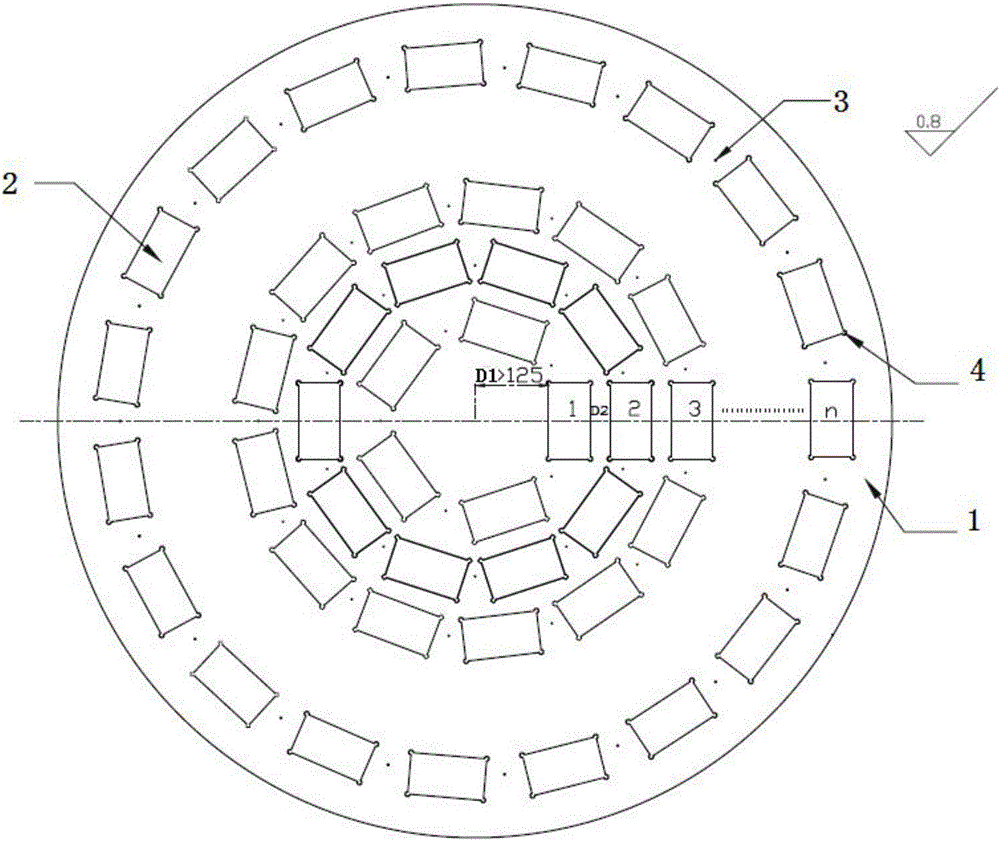

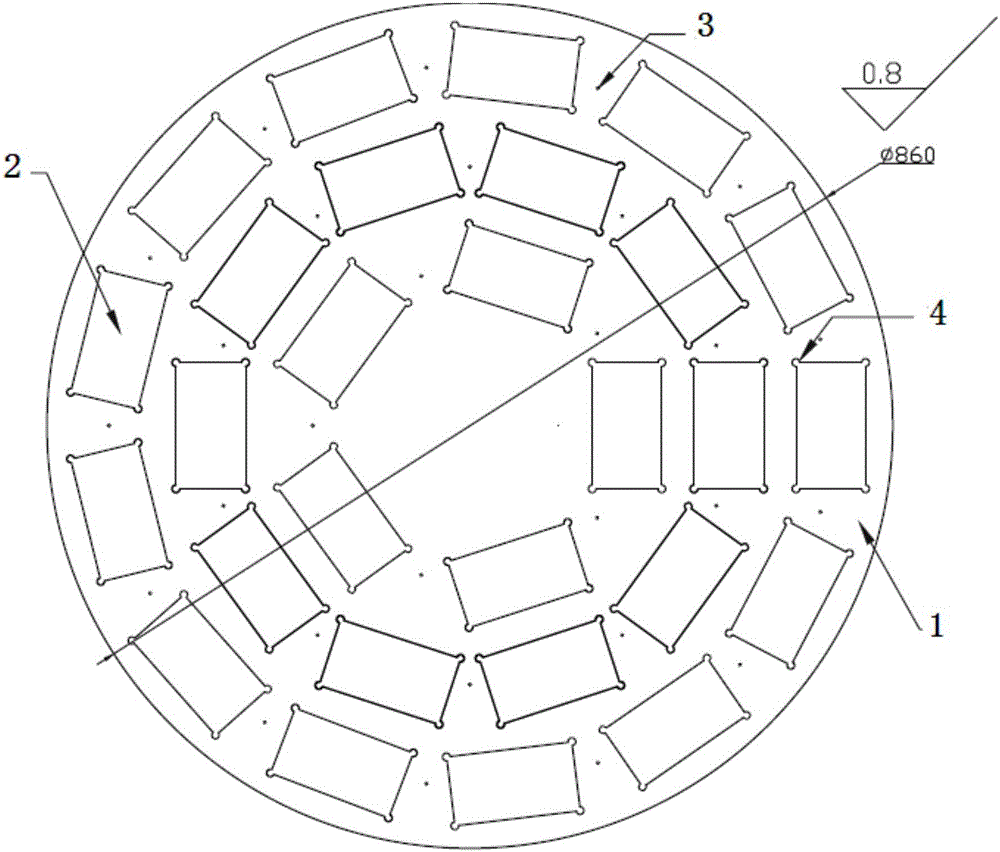

[0020] Figure 1~2 Among them, 1 is a thin plastic plate, 2 is a rectangular limiting groove, 3 is an exhaust through hole, and 4 is a radian groove.

[0021] Such as figure 1 As shown, the new small and medium-sized single-chip liquid crystal panel polishing and fixing fixture includes a plastic sheet 1, and the plastic sheet is provided with a rectangular limiting groove 2 for placing the liquid crystal panel, and the rectangular limiting groove 2 is shaped like a plastic sheet The center is the center of the circle and arranged in an equally divided annular matrix, and exhaust through holes 3 are arranged between adjacent slots in each annular matrix.

[0022] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com