Nb-containing stainless steel soldering strip and soldering flux for monolayer strip electro-slag surfacing

A single-layer strip and stainless steel technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of deterioration of welding workability, difficulty in slag removal, corrosion resistance of a large amount of residue, etc., and achieve slag removal Easy, excellent surfacing welding process performance, and beautiful weld bead formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

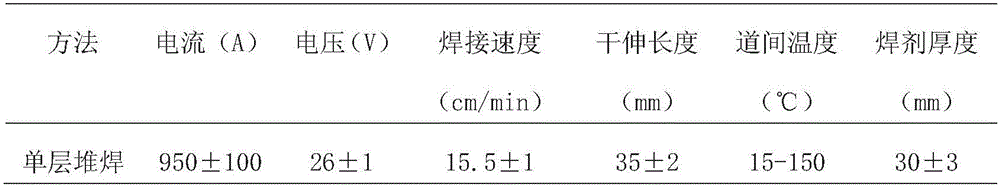

Embodiment 1

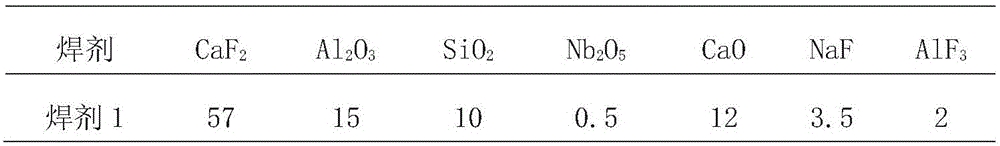

[0086] In order to achieve the purpose of the present invention, the present invention provides a kind of Nb-containing stainless steel single-layer electroslag surfacing welding strip and flux, including welding strip and flux. The flux in this embodiment is marked as flux 1, flux 1 chemical group The specific weight percentages of the components are shown in Table 1 below. The chemical components in Table 1 are sintered at 650° C. to 850° C. to prepare flux 1. The sum of the weight percentages of the chemical components of flux 1 is 100%.

[0087] Table 1 Flux 1 Chemical Component Weight Percentage (%)

[0088]

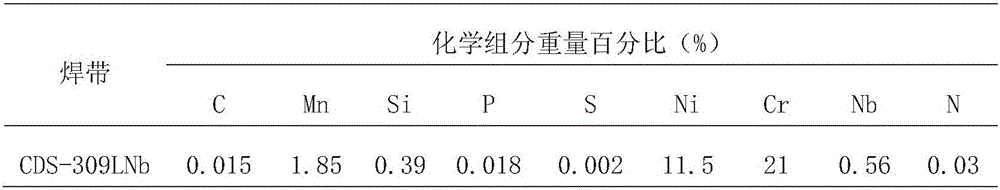

[0089] The welding strip is marked as CDS-309LNb, and the chemical composition weight percentage of welding strip 1 is shown in Table 2: the sum of the chemical composition weight percentages of the welding strip is 100%, and the balance is Fe and other unavoidable impurities. The preparation process of CDS-309LNb is as follows: the chemical components in Table 2...

Embodiment 2

[0107] In order to achieve the purpose of the present invention, the present invention provides a kind of Nb-containing stainless steel single-layer electroslag surfacing welding strip and flux, the preparation of the flux is the same as in Example 1, except that the weight of the chemical components of the flux Percentage, the flux in the present embodiment is marked as flux 2, and the specific weight percentage of described flux 2 chemical components is as follows table 7:

[0108] Table 7 Solder 2 Chemical Component Weight Percentage (%)

[0109]

[0110] The sum of the weight percentages of the chemical components of the flux 2 is 100%.

[0111] The chemical composition weight percent of the welding strip in this embodiment and the preparation of the welding strip are all the same as in Example 1, and the overlay welding process parameters in this embodiment are also the same as in Example 1, except that the flux 2 The performance of surfacing welding process is shown ...

Embodiment 3

[0123] In order to achieve the purpose of the present invention, the present invention provides a kind of Nb-containing stainless steel single-layer electroslag surfacing welding strip and flux, the preparation of the flux is the same as in Example 1, except that the weight of the chemical components of the flux Percentage, the flux in the present embodiment is marked as flux 3, and the specific weight percentage of described flux 3 chemical components is as follows table 11:

[0124] Table 11 Soldering flux 3 chemical composition weight percent (%)

[0125]

[0126] The sum of the weight percentages of the chemical components of the flux 3 is 100%.

[0127] The chemical composition weight percent of the welding strip in this embodiment and the preparation of the welding strip are all the same as in Example 1, and the overlay welding process parameters in this example are the same as in Example 1, except that the welding flux 3 The welding process performance is shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com