Grinding technology and device for wheel groove finishing broach with equal cutting angles

A technology of wheel groove broach and fine broach, which is applied in the field of grinding technology of wheel groove broach, which can solve the problems of short service life, affecting the service life of wheel groove broach, and inconsistent broaching amount, so as to reduce the cutting force , Conducive to the effect of chip curling and low error value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

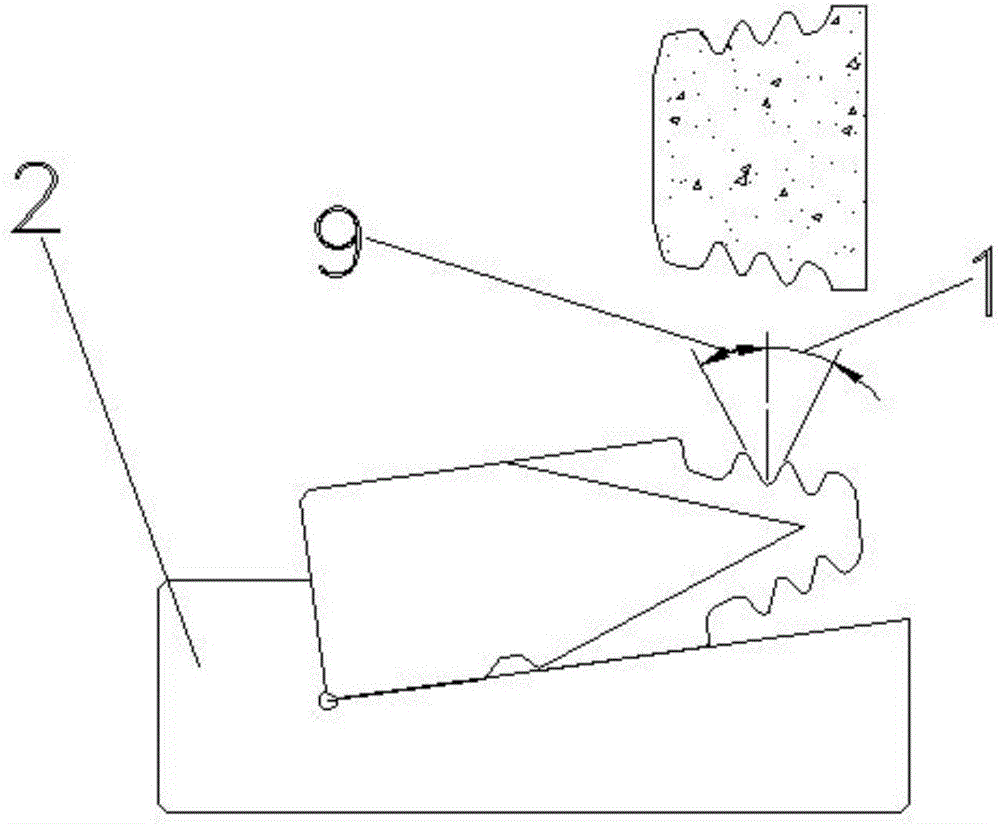

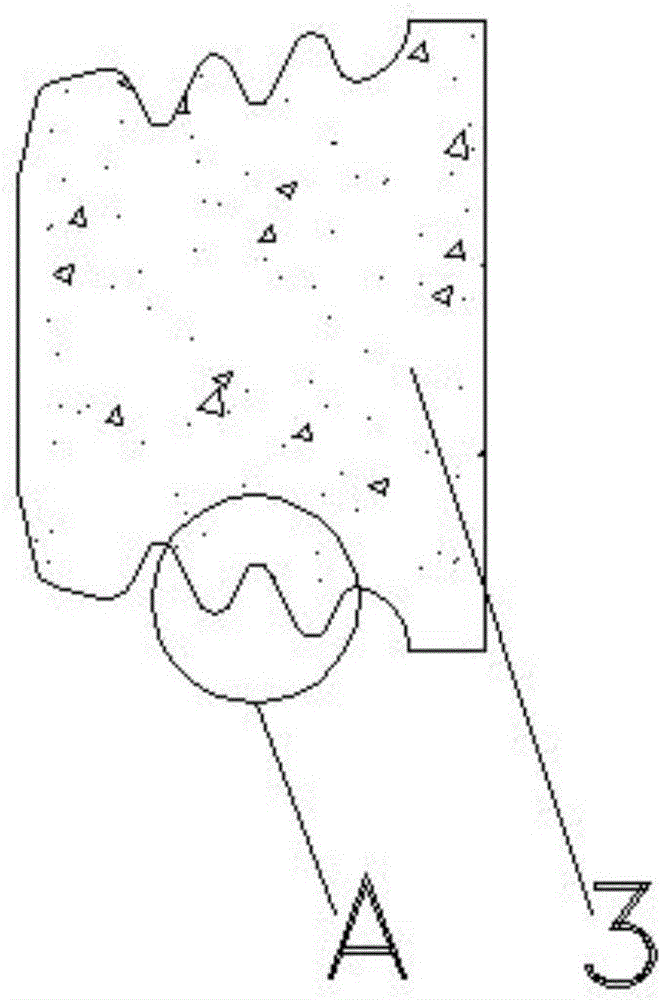

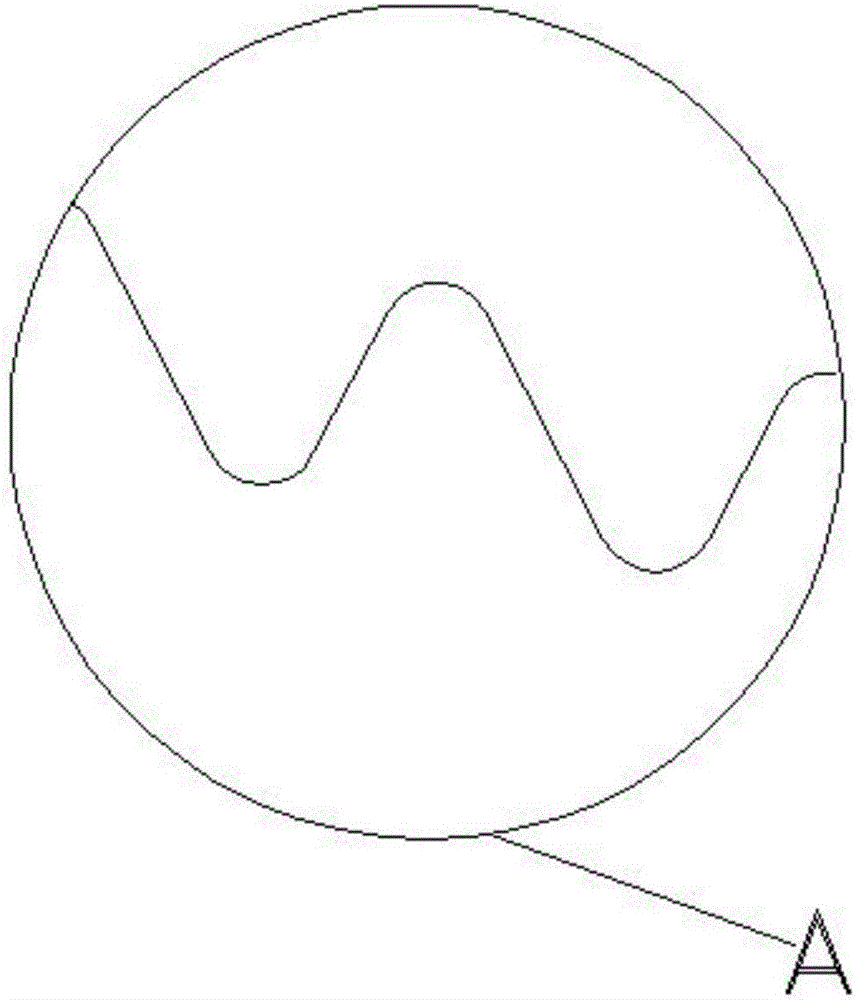

[0036] Example. A wheel groove fine broach grinding process with equal cutting angle, which is composed of figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 shown, including the following steps,

[0037] a. Based on the fact that the tooth profile angle 1 of the working surface of the fir tree tooth profile of the wheel groove broach is equal to the tooth profile angle 9 of the non-working surface of the fir tree tooth profile of the wheel slot broach, adjust the sinusoidal magnetic table 2 to the rated angle, adjust The angle range of the sinusoidal magnetic table 2 is 0 to 30 degrees, preferably 3.5 degrees; then the wheel groove broach is fixed on the sinusoidal magnetic table 2; the tooth profile angle 1 of the fir tree tooth profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com