Machining device capable of improving feeding efficiency of clutch coil shell

A processing equipment and clutch technology, applied in metal processing equipment, turning equipment, turning equipment, etc., can solve the problems of affecting the processing quality, occupying a large space of equipment, and existing safety, so as to reduce the labor intensity of workers, occupy less space for equipment, Reduce the effect of powerplants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

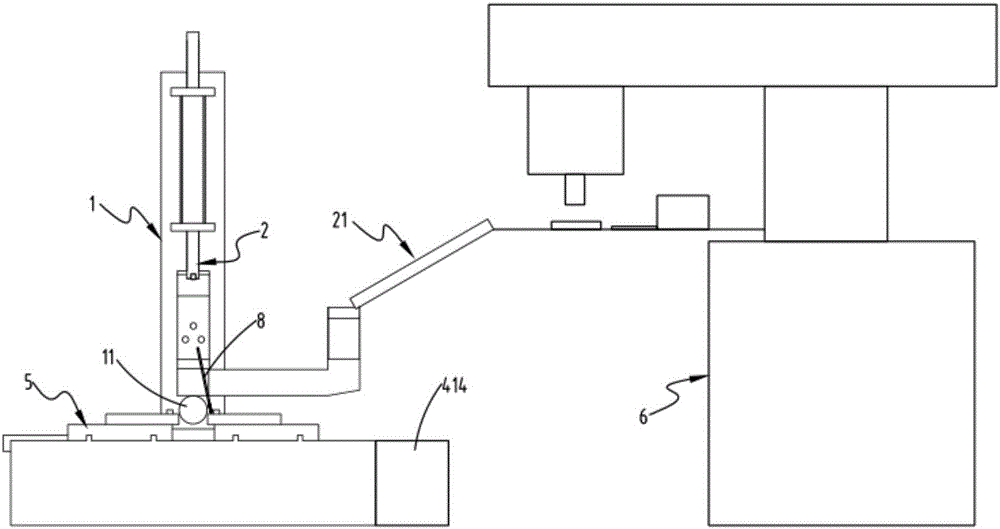

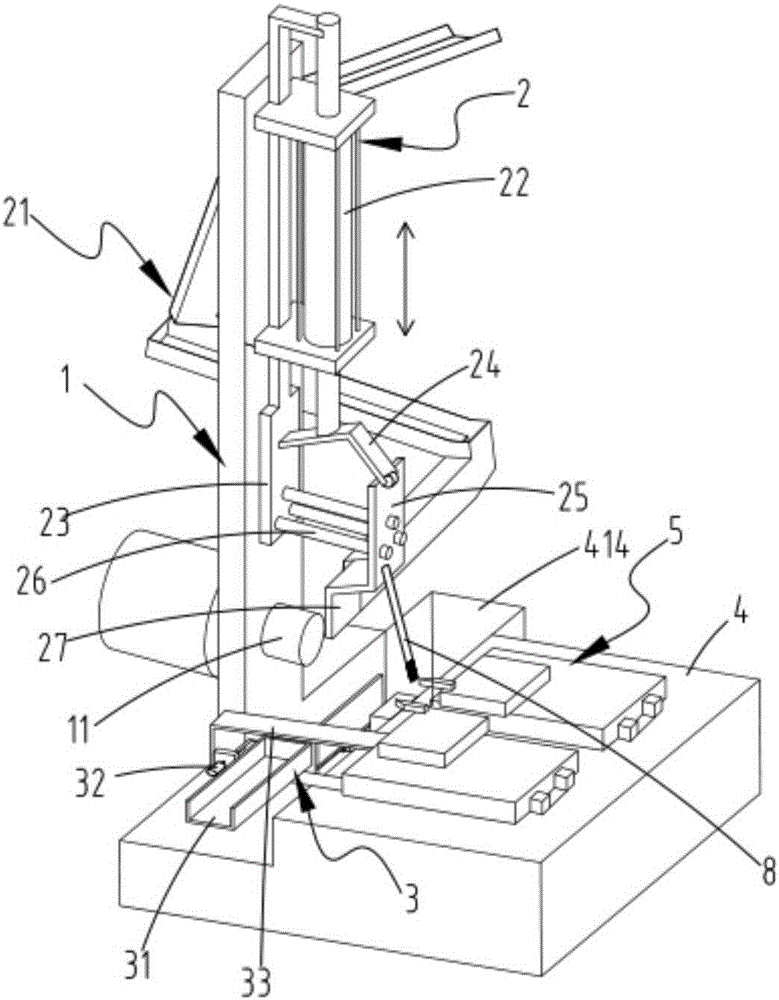

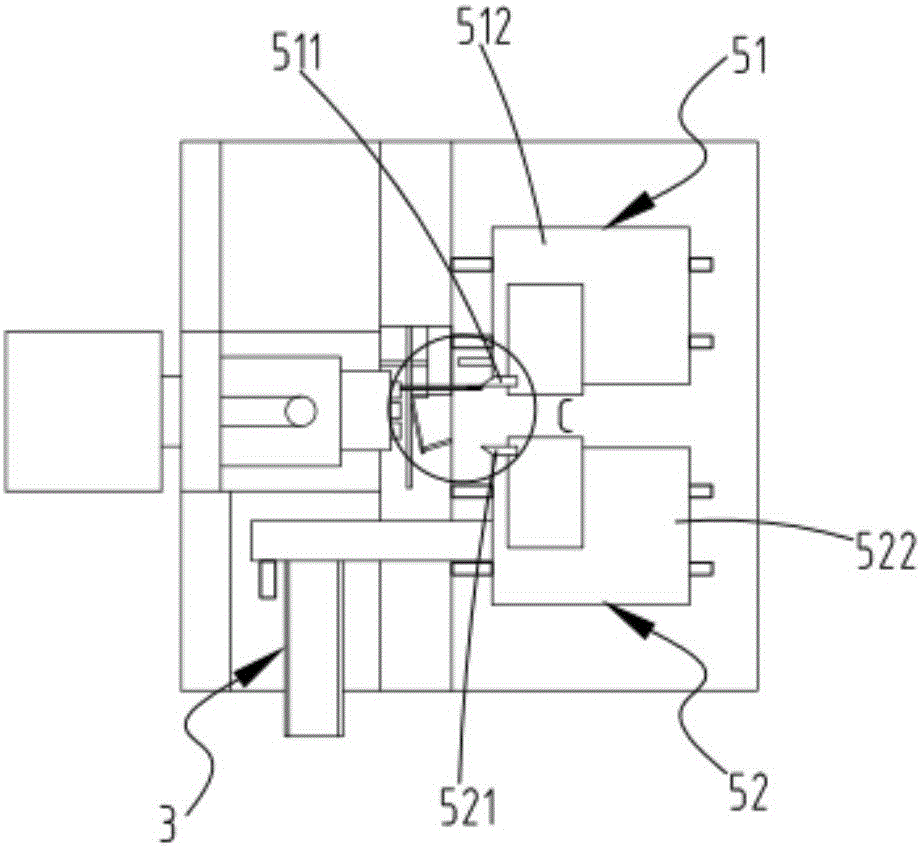

[0033] Such as figure 1 As shown, the present invention provides a processing equipment for improving the feeding efficiency of the clutch coil housing, including a frame 1, a main shaft 11 mounted on the frame 1 for driving the coil housing to rotate, and for sending the coil housing to The feeding mechanism 2 on the main shaft 11, the blanking mechanism 3 for the coil housing output after processing and the turning device 5 installed on the workbench 4, such as figure 2 As shown, the feeding mechanism 2 includes a feeding channel 21, a first driving cylinder 22 and a sliding plate 23 vertically installed on the frame 1, and the end of the piston rod of the first driving cylinder 22 is connected with an L-shaped connecting rod. Rod 24, one end of L-shaped connecting rod 24 is fixedly connected with sliding plate 23, and the other end slides and fits and connects a guide plate 25, and this guide plate 25 is arranged on the sliding plate 23 by a plurality of guide pillars 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com