New stamping mold

A stamping forming and mold technology, which is applied in the field of new stamping forming molds, can solve problems such as the deviation of the verticality of the bottom surface of the workpiece and the vertical surface, and achieve the effects of convenient maintenance and replacement, simple structure, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

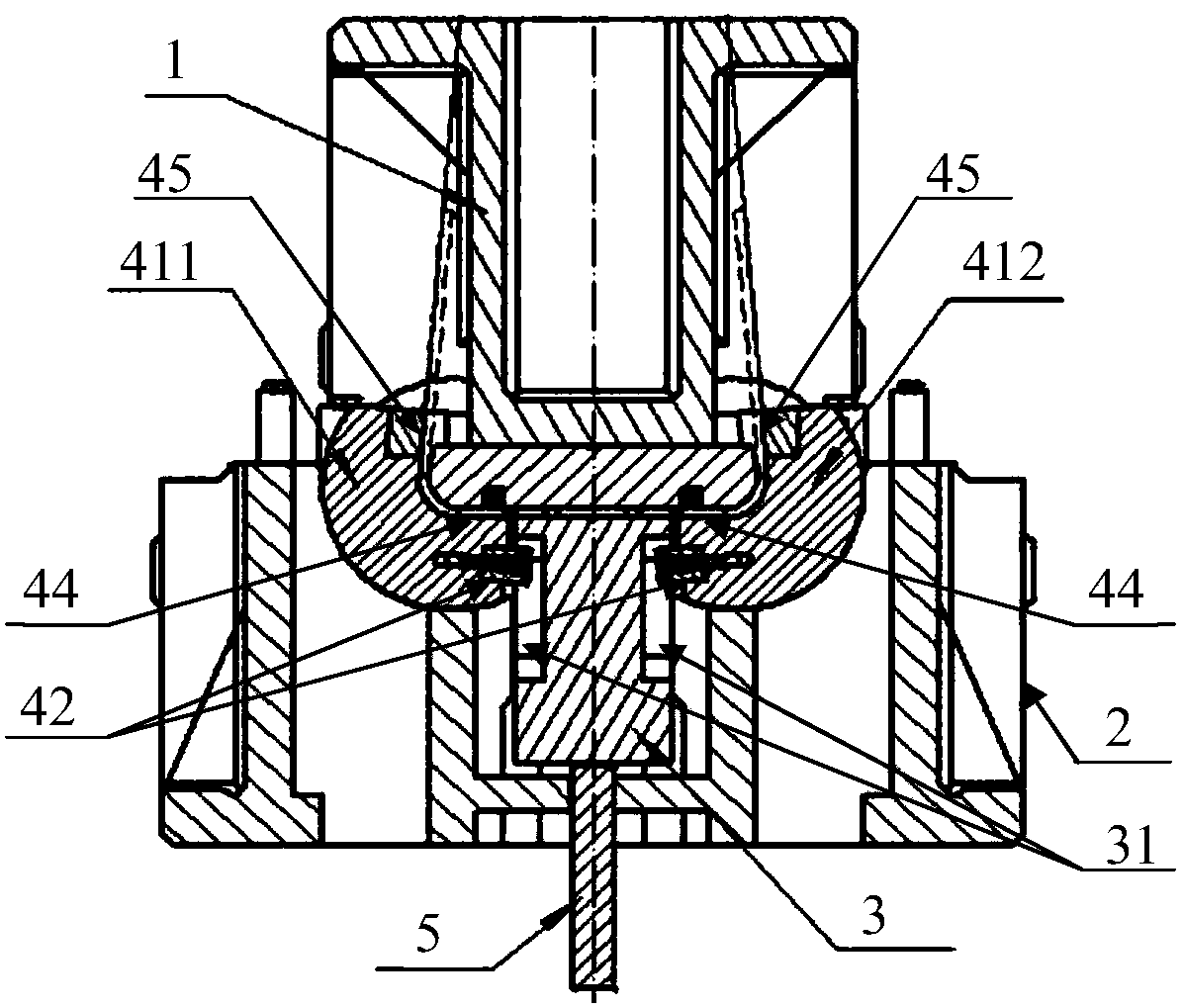

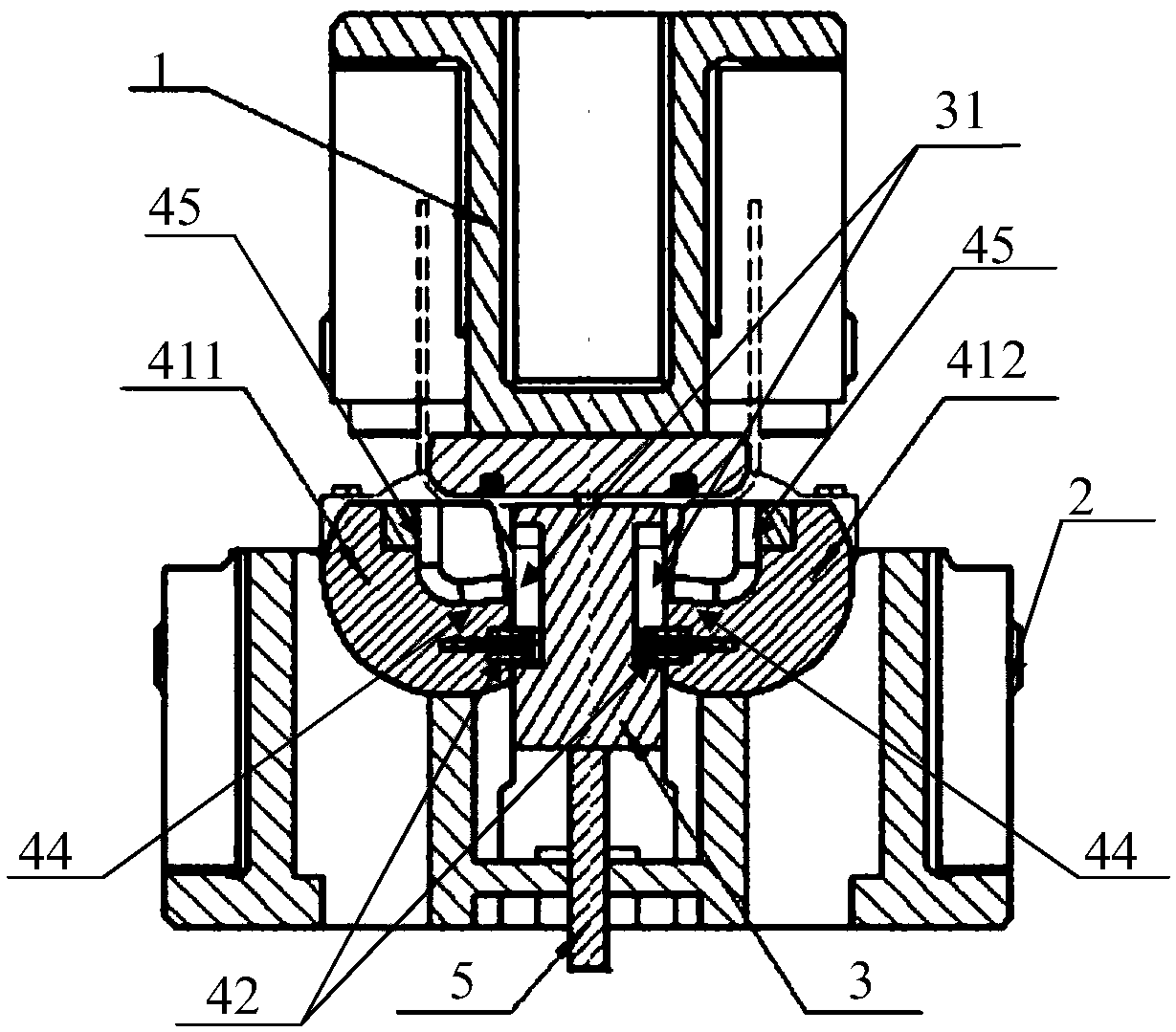

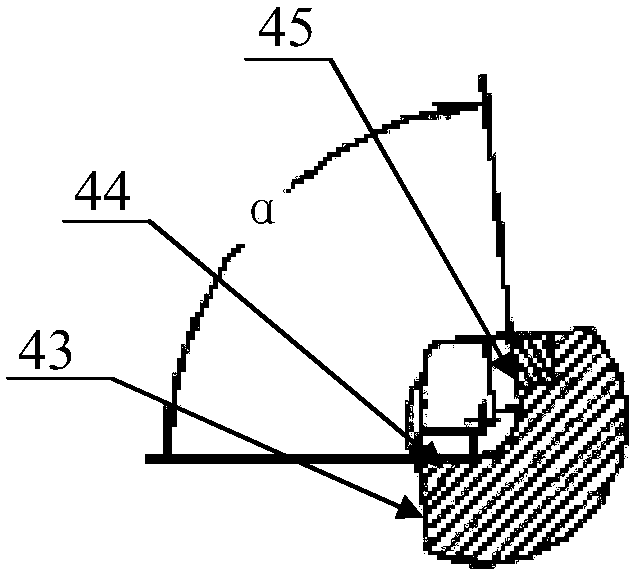

[0022] Such as figure 1 As shown, a novel stamping mold includes an upper mold 1, a lower mold base 2 and a lower mold installed in the lower mold base 2. The device and the left concave module 411 and the right concave module 412 that are symmetrically distributed on both sides of the ejector core 3 and are movably installed on the lower mold base 2 for angular rotation, the left concave module 411 and the right concave module 412 are facing the ejector core 3. One side on both sides is a concave module positioning surface 43, and the middle part of the concave module positioning surface 43 is symmetrically fixed with a positioning block 42, respectively. The elongated positioning groove 31 that moves up and down inside, the concave surface of the left concave module 411 and the right concave module 412 includes a supporting surface 44 adjacent to the concave module positioning surface 43 and a folding edge adjacent to the upper edge of the concave module. curved surface 45,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com