Intelligent measuring repair device

An intelligent measurement and equipment technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve problems such as affecting the trimming effect, complex structure, and unsatisfactory trimming effect of thin parts flatness, etc. The effect of the shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

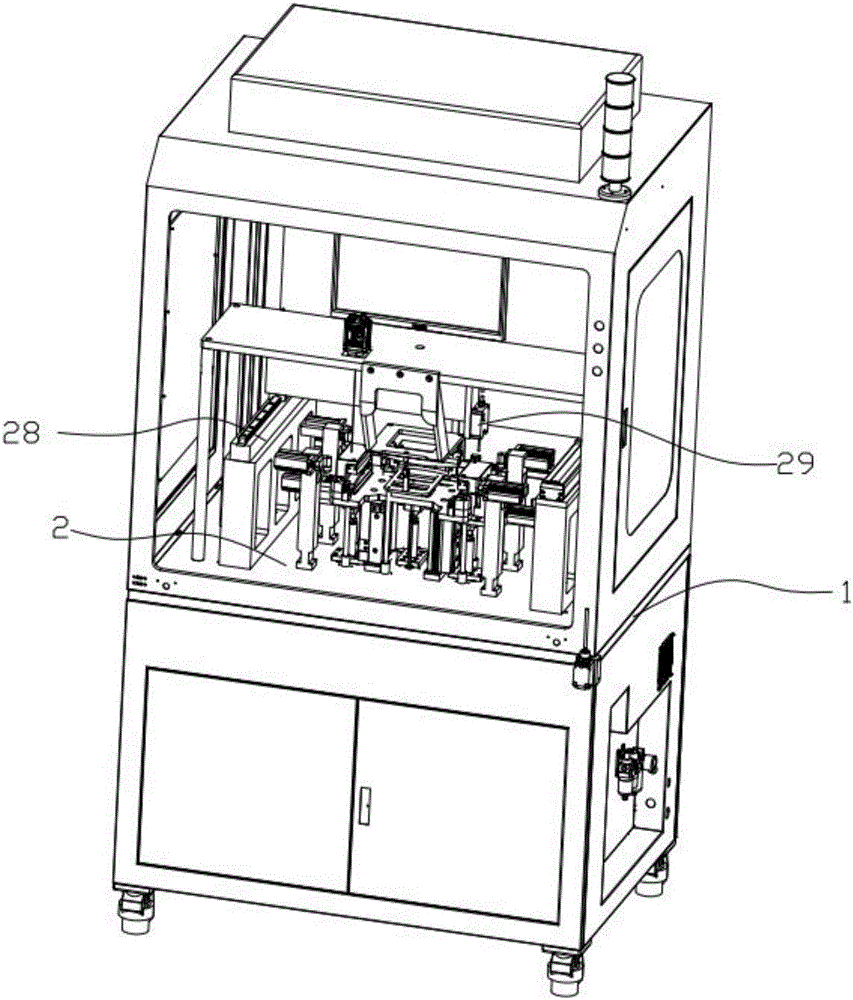

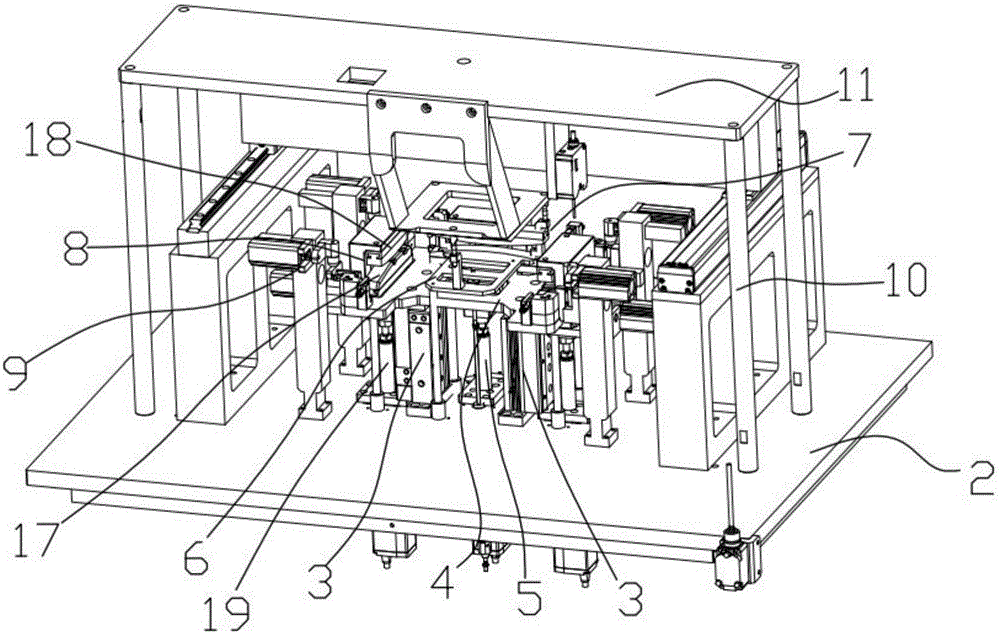

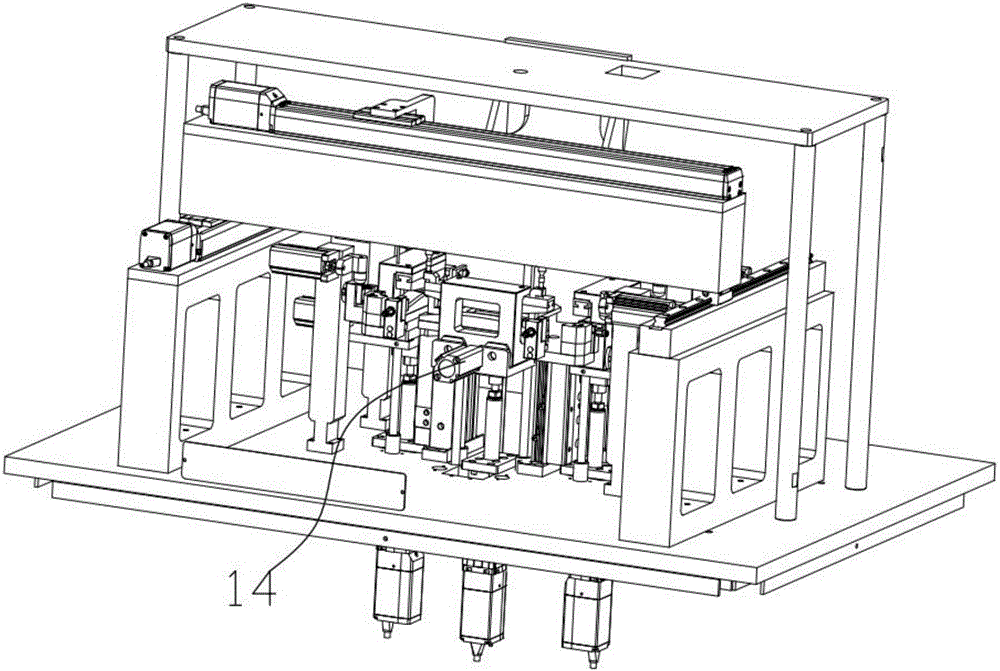

[0024] Such as figure 1 , figure 2 , image 3 As shown, the present invention proposes a kind of intelligent measurement and repair equipment, including a casing 1, a workbench 2 is provided on the casing 1, a support mechanism, a shaping mechanism, and a positioning mechanism 9 are arranged on the workbench 2, wherein , the support mechanism includes a column 10 fixed on the workbench 2, and the column 10 is provided with a mounting plate 11,

[0025] Described shaping mechanism comprises two support blocks 3, and described support block 3 is provided with carrying mechanism, and described carrying mechanism comprises bottom plate 4, and the bottom of described bottom plate 4 is provided with first air cylinder 5, and described first air cylinder 5 passes through The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com