Vacuum boiling cutting removing device

A technology of vacuum boiling and vacuum generation, which is applied in the direction of dust removal, metal processing machinery parts, maintenance and safety accessories, etc., to achieve good chip removal effect, improve emission compliance rate, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

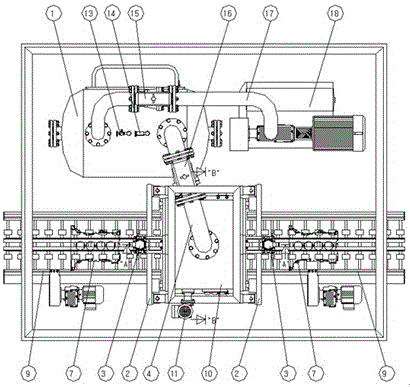

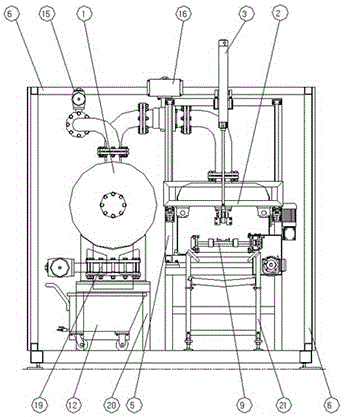

[0027] Such as Figure 1-Figure 6 The shown vacuum boiling chip removal device includes the workpiece 7 which is transported through the transmission mechanism and placed in the workpiece warehouse 10. The cavity of the workpiece warehouse 10 is a tunnel-type cavity formed by plate welding, and the two ports of the workpiece warehouse 10 are connected to the warehouse. The door sealing mechanism and the workpiece warehouse 10 are connected with a vacuum generating mechanism.

[0028] The vacuum generating mechanism includes a vacuum pump 18 connected to the sealed isolation tank 1 through the pipeline 17, and the sealed isolation tank 1 is connected to the workpiece warehouse 10 through the external pipeline 4 of the workpiece warehouse. The pipeline 4 is equipped with a workpiece warehouse air extraction automatic control valve 16 , and a workpiece warehouse air injection automatic control valve 24 is installed between the workpiece warehouse air extraction automatic control ...

Embodiment 2

[0039] The structural connections and working process of the vacuum boiling chip removal device in this embodiment are the same as those in Embodiment 1, and the different technical parameters are: during operation, the vacuum degree of the isolation tank 1 is set to 25 mbar.

Embodiment 3

[0041] The structural connections and working process of the vacuum boiling chip removal device in this embodiment are the same as those in Embodiment 1 and Embodiment 2, and the different technical parameters are: during operation, the vacuum degree of the isolation tank 1 is set to 50 mbar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com