Catalyst for production of acetylene method vinyl acetate

A vinyl acetate and catalyst technology, applied in the field of acetylene gas phase method vinyl acetate synthesis, can solve problems such as low catalyst activity, and achieve the effects of improving activity and stability and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

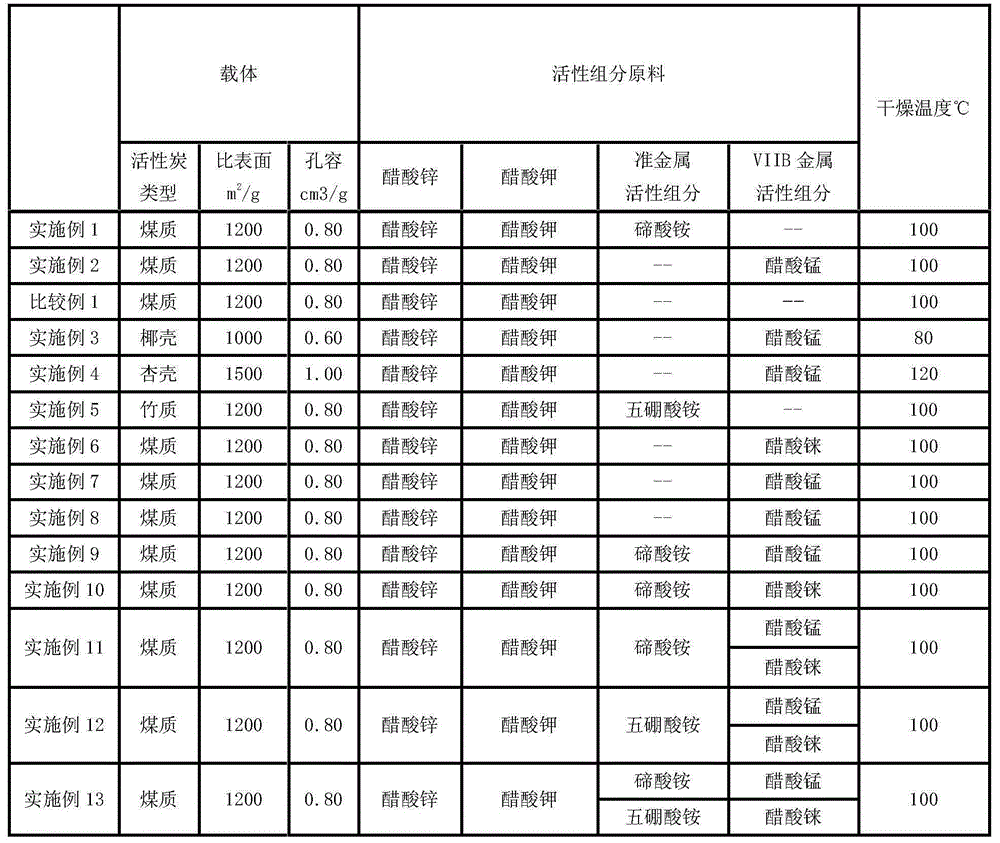

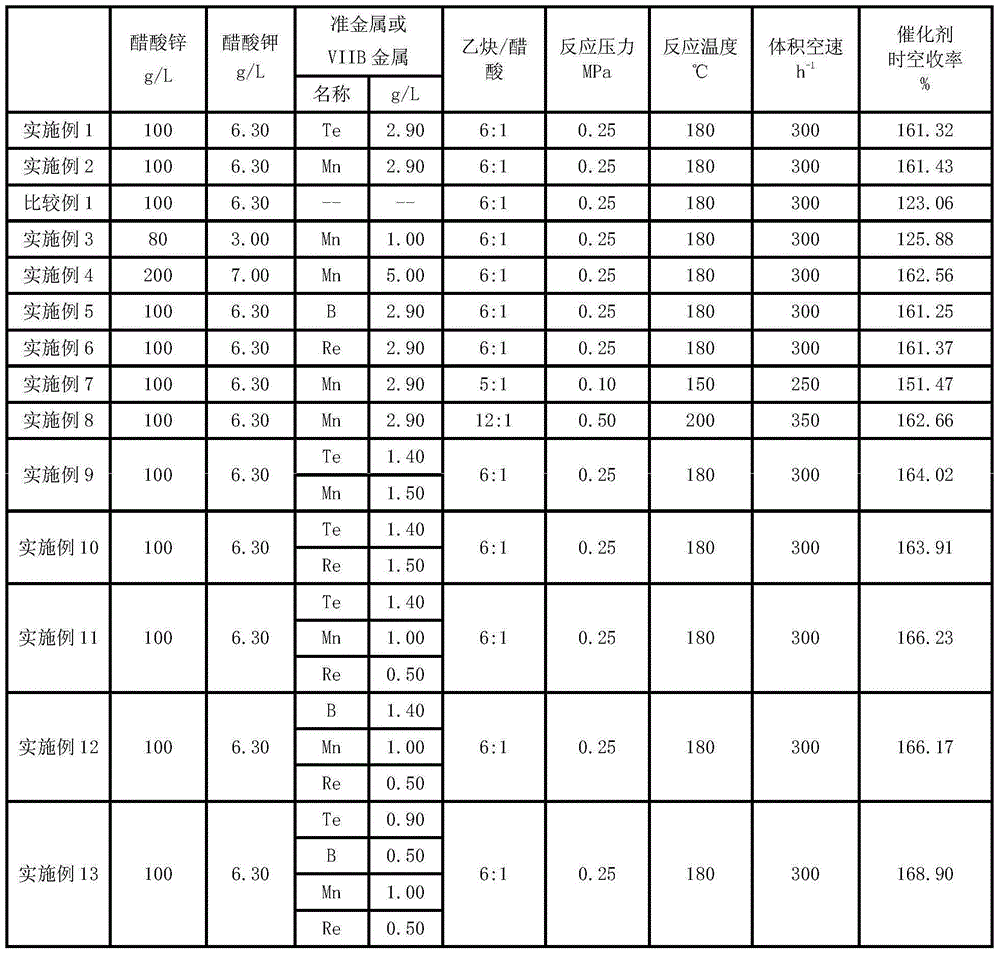

Examples

Embodiment 1

[0024] The preparation of catalyst: will contain 100g zinc acetate (Zn(OAc) 2 ), containing 6.30g potassium acetate (KOAc) and ammonium tellurate containing 2.90g Te ((NH 4 ) 2 TeO 4 ) is fully mixed and dissolved in an aqueous solution of acetic acid with a concentration of 60wt%, to obtain 350ml of impregnation solution, and 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200cm 2 / g of coal-based cylindrical activated carbon carrier was impregnated in the above impregnating solution, and dried at 100°C for 3 hours to obtain the catalyst. The Zn content of the catalyst was determined by ICP to be 100g / L, the K content to be 6.30g / L, and the Te content to be 2.90g / L.

[0025] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid...

Embodiment 2

[0029] The preparation of catalyst: will contain 100g zinc acetate (Zn(OAc) 2 ), containing 6.30g potassium acetate (KOAc) and manganese acetate (Mn(OAc) containing 2.90gMn 2 4H 2 O) fully mixed and dissolved in acetic acid aqueous solution with a concentration of 60wt%, to obtain 350ml of impregnation solution, 1L of 3mm in diameter, 2cm in length, and 0.80cm in pore volume 3 / g, the specific surface area is 1200cm 2 / g of coal-based cylindrical activated carbon carrier was impregnated in the above impregnating solution, and dried at 100°C for 3 hours to obtain the catalyst. The Zn content of the catalyst measured by ICP is 100g / L, the K content is 6.30g / L, and the Mn content is 2.90g / L.

[0030] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction tem...

Embodiment 3

[0041] The preparation of catalyst: will contain 80g zinc acetate (Zn(OAc) 2 ), containing 3.00g potassium acetate (KOAc) and manganese acetate containing 1.00gMn (Mn(OAc) 2 4H 2 O) fully mixed and dissolved in acetic acid aqueous solution with a concentration of 60wt%, to obtain 350ml of impregnation solution, 1L of 3mm in diameter, 2cm in length, and 0.60cm in pore volume 3 / g, the specific surface area is 1000cm 2 / g cylindrical coconut shell activated carbon carrier was immersed in the above impregnating solution, and dried at 80° C. for 3 hours to obtain the catalyst. The Zn content of the catalyst measured by ICP is 80g / L, the K content is 3.00g / L, and the Mn content is 1.00g / L.

[0042] The synthesis of vinyl acetate: 30ml catalyst is packed in the miniature fixed-bed reactor, with N 2 After leak test, use N 2 Fully purge the system, after the system heats up, turn off the N 2 , cut into acetylene in turn, turn on the acetic acid pump, control the reaction tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Space-time yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com