Energy-saving double-circulation desulfurization system

A desulfurization system, dual-cycle technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of low adjustment accuracy, unstable performance, poor energy saving effect, etc., to achieve a simple and reliable system and complete control logic matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

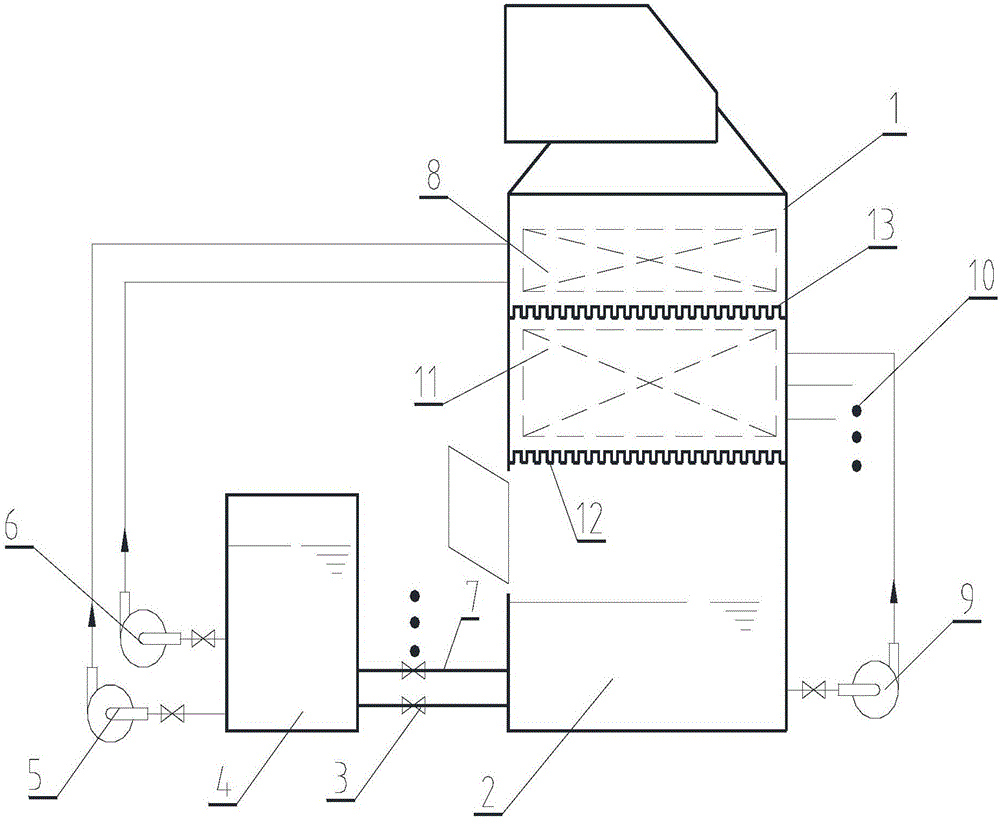

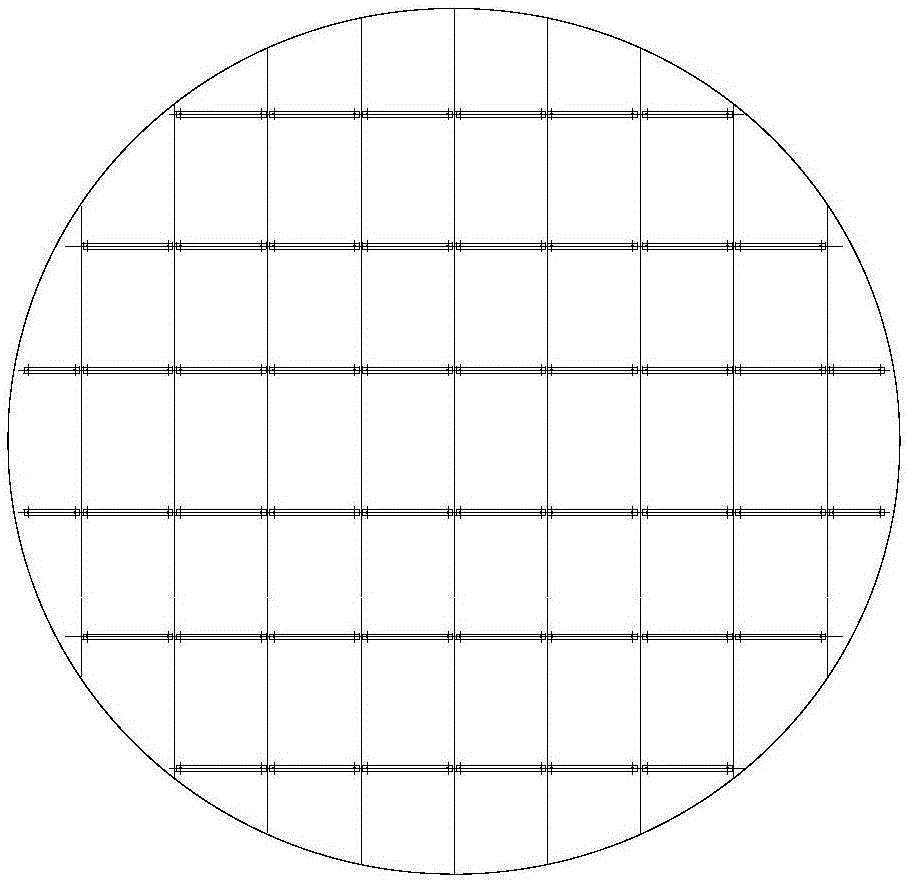

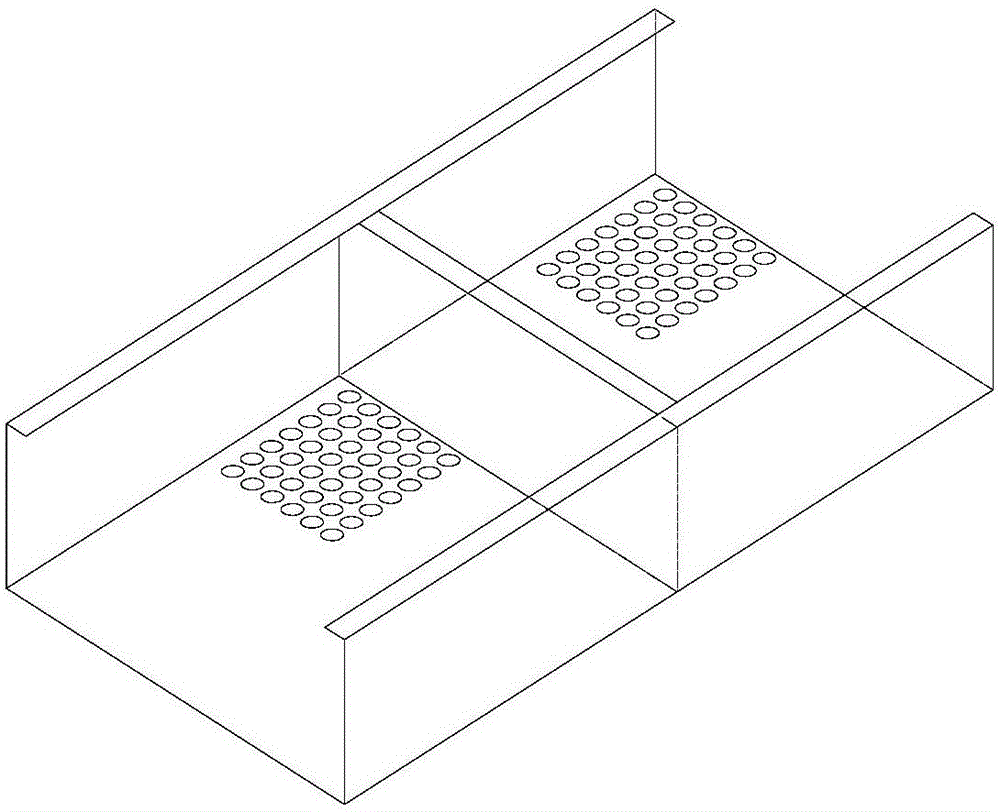

[0015] This energy-saving dual-cycle desulfurization system includes an absorption tower 1, an absorption tower pulp pool 2, and an outer pulp pool 4. The absorption tower pulp pool 2 and the tower outer pulp pool 4 are connected in an array multi-channel manner. The top of the tower 1 is provided with an absorption tower spray layer 11, and the absorption tower slurry pool 2 is connected with multiple absorption tower slurry circulation pumps 10; the absorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com