Circular pig house with nested intake passages and exhaust passages and pig farming method

A technology of air outlet channel and air inlet channel, which is applied in the field of pig breeding, and can solve the problems of large odor in the pig house and its surroundings, inability to seal it, and failure to meet the standard for pork drug residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

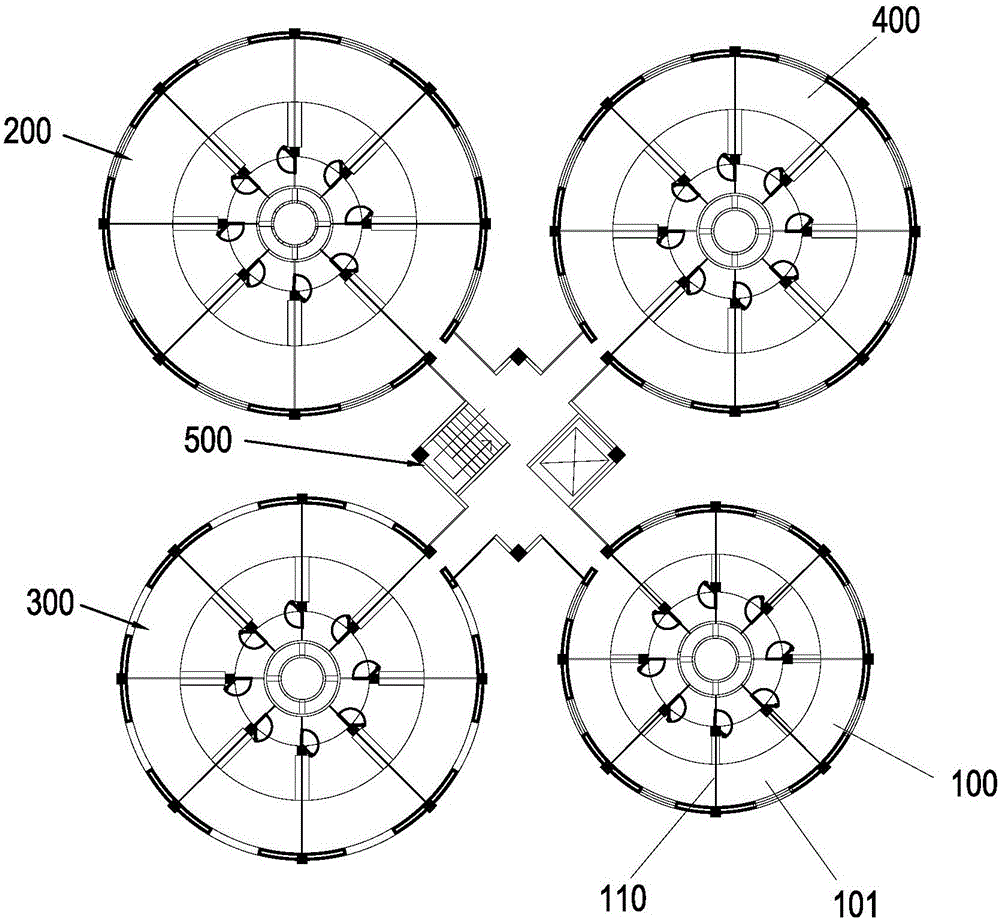

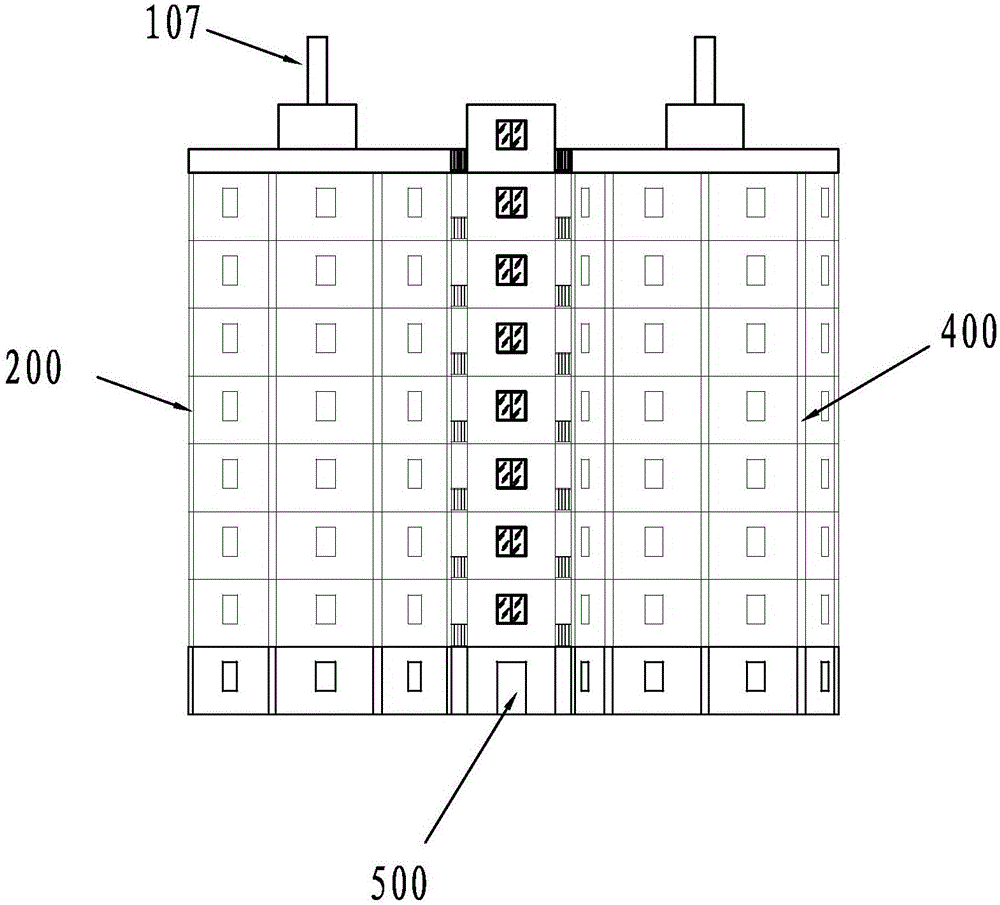

[0029] See figure 1 with figure 2 , The pig house of the present invention includes four cylindrical buildings, namely the first pig house 100, the second pig house 200, the third pig house 300 and the fourth pig house 400. These 4 pig houses are arranged as Square, and the shape and structure of each building are consistent. There is a passage and auxiliary facility building 500 in the middle of the four pig house buildings, and the passage and auxiliary facility building 500 has an elevator room 501 and a step room 502.

[0030] The first pigsty building 100, the second pigsty building 200, the third pigsty building 300, and the fourth pigsty building 400 form a breeding unit with the passage and auxiliary facility building 500.

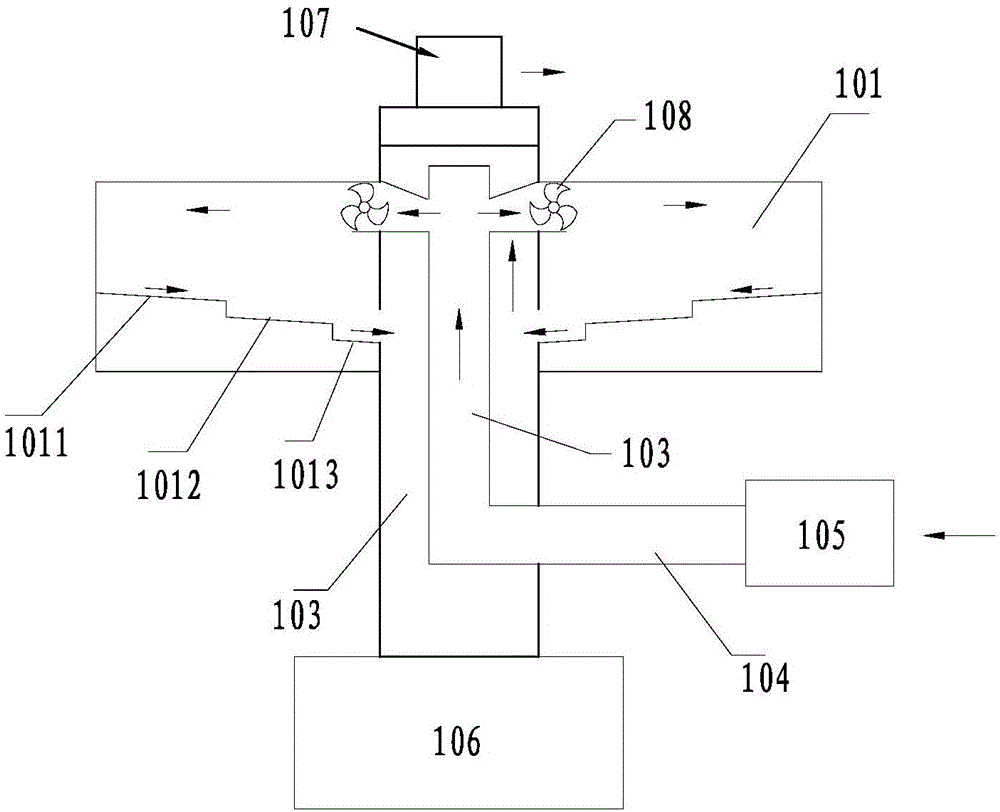

[0031] In all the examples, the cylindrical building has 8 floors, each floor is 3.9 meters high, the bottom layer collects feces and urine, treats air, and 2-8 floors raise pigs. The "outside" refers to the direction from the center of the circle to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com