Method for preparing secondary perovskite solar cell

A technology of solar cells and secondary calcium, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of recycling and reuse of batteries polluted by Pb elements, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

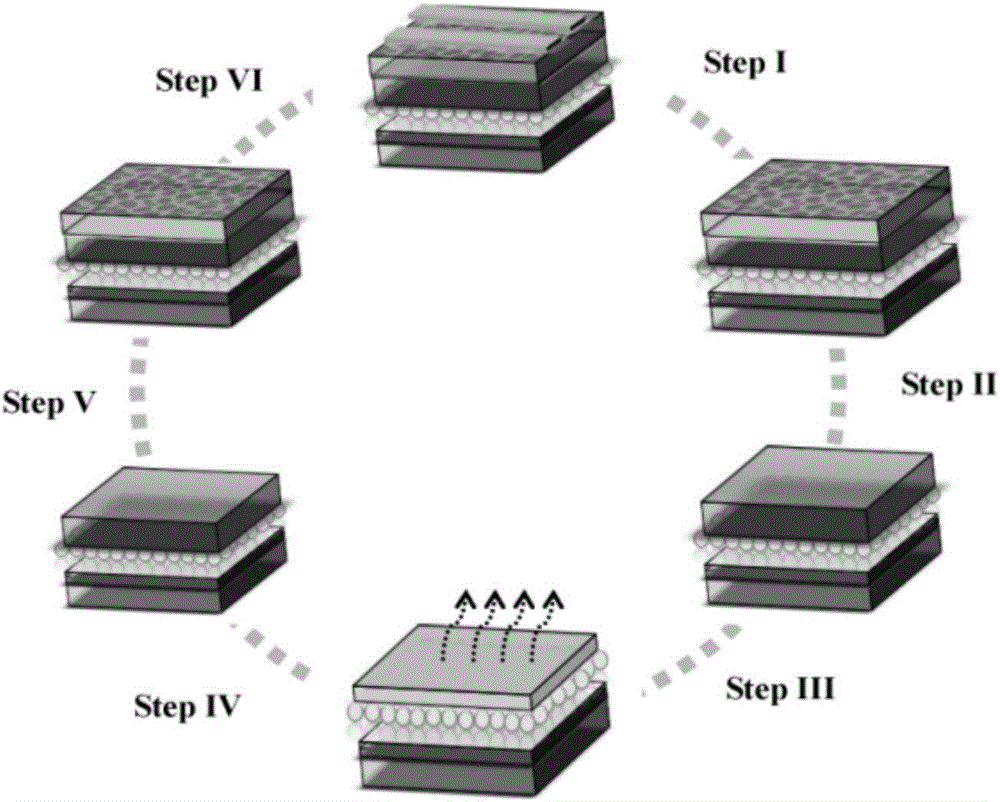

Image

Examples

Embodiment 1

[0028] To recycle porous perovskite battery structure: glass / transparent conductive film / dense TiO 2 / Porous TiO 2 / perovskite CH 3 NH 3 PB 3 / Hole transport layer [2,2,7,7-tetrakis(N,N-di-p-methoxyphenlamine)-9,9′-spiro-bifluorene](spiro-MeOTAD) / Ag as an example,

[0029] Concrete preparation steps are as follows:

[0030] (1) Use adhesive tape to remove metallic silver;

[0031] (II) Submerge the battery substrate with the metal electrodes removed in the chlorobenzene solution, dissolve and remove the hole transport layer spiro-MeOTAD; the chlorobenzene solution adopts pure chlorobenzene;

[0032] (III) Perovskite material CH 3 NH 3 PB 3 Decompose into solid PbI by heating at 250 degrees for 10 minutes 2 and the volatile gas methylammonium iodide CH 3 NH 3 I;

[0033] (IV) by spin-coating methylammonium iodide CH 3 NH 3 I, solution secondary growth of the corresponding perovskite film CH 3 NH 3 PB 3 ;

[0034] (V) preparation of hole transport layer spiro-...

Embodiment 2

[0040] To recycle porous perovskite battery structure: glass / transparent conductive film / dense TiO 2 / Porous TiO 2 / perovskite CH 3 NH 3 PbBr 3 / hole transport layer P 3 HT / Ag as an example,

[0041] Specific steps are as follows:

[0042] (1) Use adhesive tape to remove metallic silver;

[0043] (II) Immerse the battery with the metal electrode removed in the chlorobenzene solution, dissolve and remove the hole transport layer P 3 HT; Chlorobenzene solution adopts pure chlorobenzene;

[0044] (III) Perovskite material CH 3 NH 3 PbBr 3 PbBr decomposed into solid state by heating at 250 degrees for 30 minutes 2 and the volatile gas methylammonium iodide CH 3 NH 3 Br;

[0045] (IV) by spin-coating methylammonium iodide CH 3 NH 3 Br solution, the secondary growth of the corresponding perovskite film CH 3 NH 3 PbBr 3 ;

[0046] (V) preparation of hole transport layer spiro-MeOTAD;

[0047] (VI) Evaporate Ag electrodes.

[0048] The first step of recovering ...

Embodiment 3

[0052] To recycle planar perovskite cell structure: glass / transparent conductive film / dense TiO 2 / CH 3 NH 3 PB 3 / hole transport layer P 3HT / Ag as an example,

[0053] Specific steps are as follows:

[0054] (1) Use adhesive tape to remove metallic silver;

[0055] (II) Immerse the battery with the metal electrode removed in the chlorobenzene solution, dissolve and remove the hole transport layer P 3 HT; Chlorobenzene solution adopts pure chlorobenzene;

[0056] (III) Perovskite material CH 3 NH 3 PB 3 Decompose into solid PbI by heating at 250 degrees for 30 minutes 2 and the volatile gas methylammonium iodide CH 3 NH 3 I;

[0057] (IV) by soaking methyl ammonium iodide CH 3 NH 3 I, secondary growth of the corresponding perovskite film CH 3 NH 3 PB 3 ;

[0058] (V) preparation of hole transport layer spiro-MeOTAD;

[0059] (VI) Evaporate Ag electrodes.

[0060] The first step of recovering the Ag electrode and the second step of the hole transport layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com