Painting mixing apparatus for painting manufacturing

A control device and paint mixing technology, applied in control/adjustment systems, multiple fluid ratio control, ratio control, etc., can solve the problems of low efficiency, labor-intensive, inability to deploy paints for lacquer painters, etc., and achieve enhanced The effect of deployment, improving deployment efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

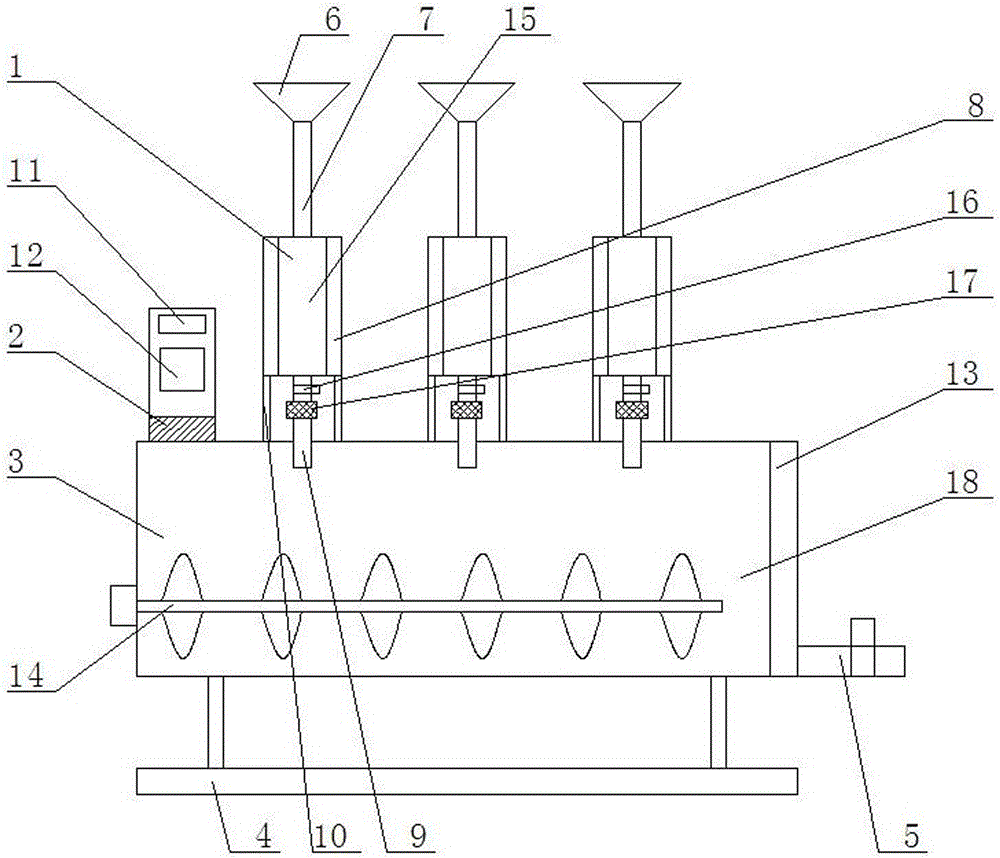

[0016] like figure 1 As shown, a paint mixing device for lacquer painting production includes a feeding device 1, a control device 2, a blending device 3, a support seat 4, and a discharge pipe 5. The top of the device 3 and the right end of the control device 2 are equipped with three feeding devices 1, the right side of the blending device 3 is equipped with a discharge pipe 5, and the bottom end of the blending device 3 is equipped with a support seat 4; Material pipe 7, transfer storage box 8, feed pipe 9, support frame 10, the lower end of the feed hopper 6 is connected to the transfer storage box 8 through the feed pipe 7, and the bottom end of the transfer storage box 8 passes through the support frame The device 10 is at the upper end of the blending device 3, and the middle of the bottom end of the transfer storage box 8 is connected to the blending device 3 through the feed pipe 9; the control device 2 is connected to control the feeding device 1 and the blending dev...

Embodiment 2

[0018] like figure 1 As shown, the transparent observation window 15 is installed on the front side of the transfer storage bin 8 .

Embodiment 3

[0020] like figure 1 As shown, an electric control valve 16 and a flow meter 17 are installed on the feed pipe 9 from top to bottom; the electric control valve 16 and flow meter 17 are all connected to the control device 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com