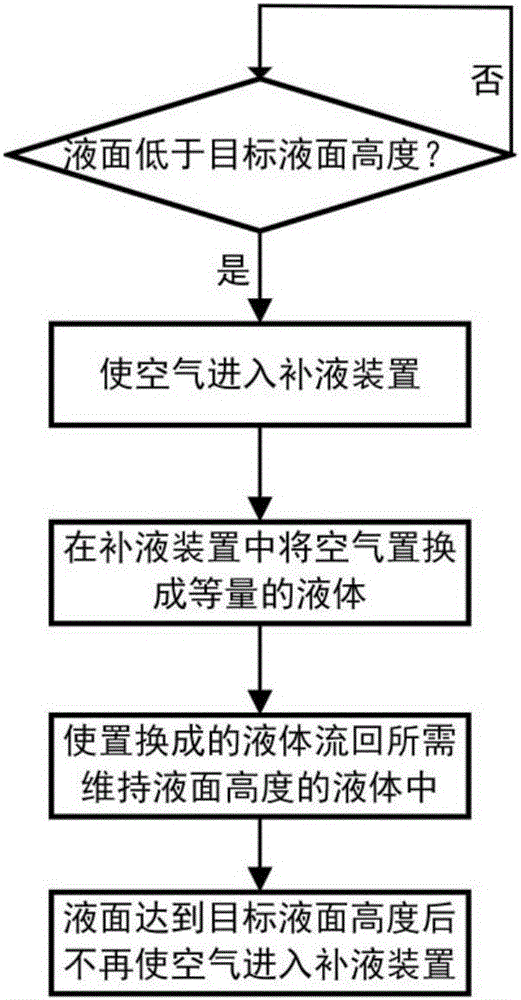

Liquid level automatic maintenance device and method

A technology of liquid level height and liquid replenishment device, which is applied in liquid level control, non-electric variable control, instruments, etc., can solve problems such as overflow and safety hazards, and achieve convenient installation, high stability and safety, and high maintenance accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

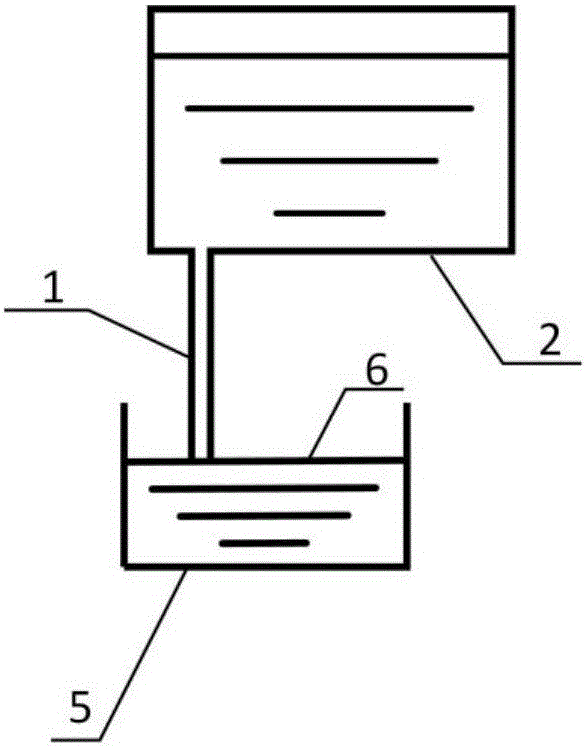

[0034] This embodiment provides a simple and convenient liquid level automatic maintenance device, its structure is as follows: figure 2 As shown, it includes a vent tube 1 and a sealed fluid replacement device 2 . The upper end of the vent pipe 1 is connected to the water outlet of the sealed fluid replacement device 2 , and the nozzle at the lower end of the vent pipe 1 is located at the target liquid level height 6 in the container 5 .

[0035] The sealed liquid replenishment device 2 is a closed water tank, and the water outlet is at the bottom of the device, and the water outlet remains below the liquid level during the maintenance of the liquid level. Place the sealed liquid replenishment device 2 at a high place so that the liquid level therein is higher than the target liquid level height 6, and the liquid in the sealed liquid replenishment device 2 that is higher than the target liquid level is subjected to downward gravity to make the air pressure in the sealed liqu...

Embodiment 2

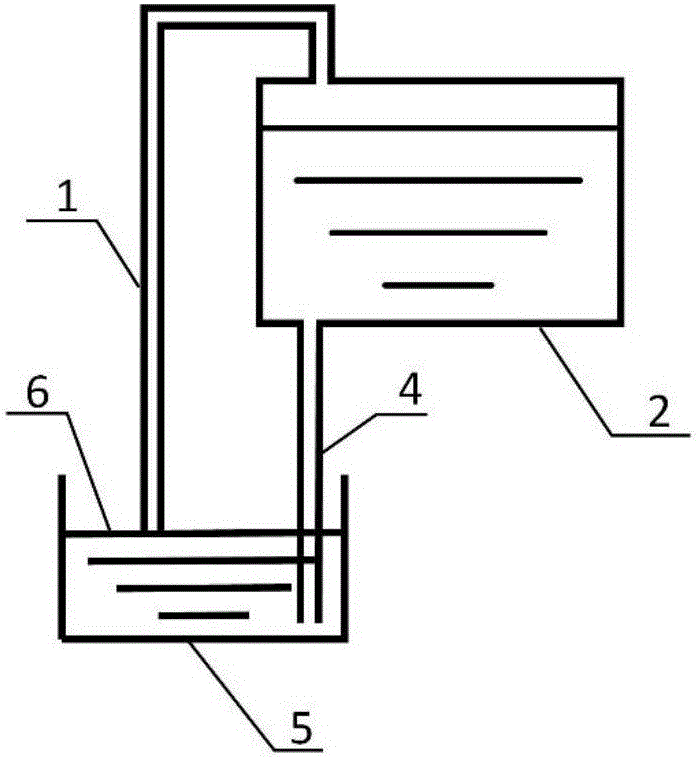

[0038] This embodiment provides a liquid level automatic maintenance device that separates air intake and liquid addition. The device is as follows: image 3 As shown, it includes a vent pipe 1 , a sealed fluid replacement device 2 and a first water outlet pipe 4 . The ventilation pipe 1 is connected with the upper air inlet of the sealed liquid replenishment device 2 , and the water outlet of the sealed liquid replenishment device 2 is connected with the top (water inlet) of the first water outlet pipe 4 .

[0039] The nozzle at the lower end of the vent pipe 1 is located at the target liquid level 6 in the container 5 .

[0040] The sealed liquid replenishment device 2 is a closed water tank, and the water outlet is at the bottom of the device, and the water outlet remains below the liquid level during the maintenance of the liquid level. Place the sealed liquid replenishment device 2 at a high place so that the liquid level in it is higher than the target liquid level heig...

Embodiment 3

[0045] This embodiment provides a liquid level automatic maintenance device that is easy to place, and its structure is as follows: Figure 4 As shown, the device includes a ventilation pipe 1 , a sealed liquid replenishment device 2 , a water pump 3 , a second water outlet pipe 7 and a water replenishment pipe 8 .

[0046]The nozzle at one end of the ventilation tube 1 is located at the target liquid level 6 in the container 5 , and the other end communicates with the air inlet at the top of the sealed liquid replacement device 2 . The sealing liquid replenishing device 2 is a gas washing bottle used in reverse. One end of the second outlet pipe 7 enters from the water outlet of the sealing liquid replenishing device 2 and extends below the liquid level in the device, and the other end is connected to the water inlet of the water pump 3 . What water pump 3 adopted is micro gear pump, and the rotating speed of gear pump is adjustable. The water outlet of the replenishment pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com