Array substrate, manufacturing method thereof and LCD (Liquid Crystal Display)

An array substrate and pixel array technology, which is applied in the field of VA liquid crystal display and liquid crystal display, can solve the problems of insufficient display LCMargin, poor picture display effect, insufficient elastic compression, etc., so as to avoid the loss of transmittance, improve competitiveness, The effect of increasing the contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will describe in detail with reference to the accompanying drawings, the array substrate and its manufacturing method, and the liquid crystal display of the present invention.

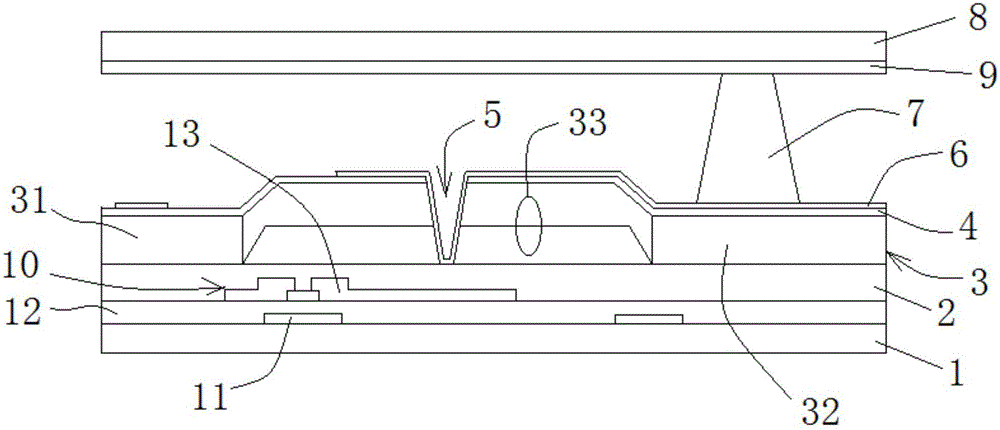

[0032] combine figure 1 , the array substrate proposed by the present invention will be described in detail.

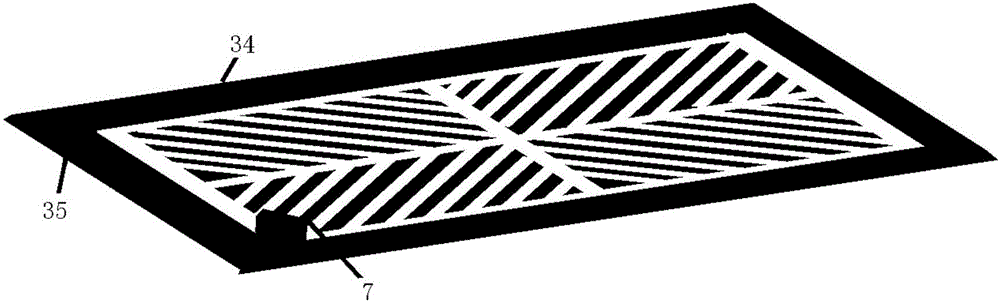

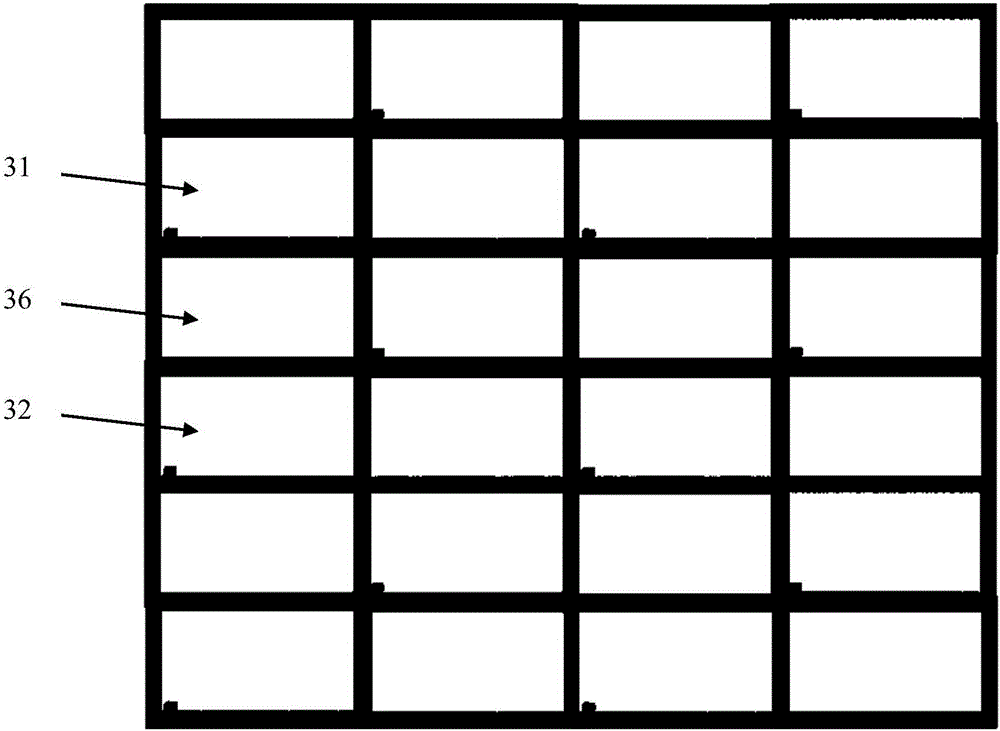

[0033] The array substrate proposed by the present invention, from bottom to top, is a glass substrate 1 containing a thin film transistor array, a first passivation layer 2, a red, green and blue pixel array layer 3, a second passivation layer 4, via holes 5, a second passivation layer A transparent conductive layer 6 , in the red, green and blue pixel array layer 3 , red and blue resist stacks 33 are arranged between pixels.

[0034] The thin film transistor includes a first metal layer 11, a gate insulating layer 12, an active layer, an ohmic contact layer, and a second metal layer 13 from bottom to top, and the first metal layer includes a gate electrode and an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com