Circulation loop-type flow corrosion testing apparatus, and testing method

A technology of flow corrosion and circulation loop, which is applied in the direction of measuring devices, testing wear resistance, instruments, etc., can solve the problem that the critical characteristics of flow corrosion cannot be quantitatively tested, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

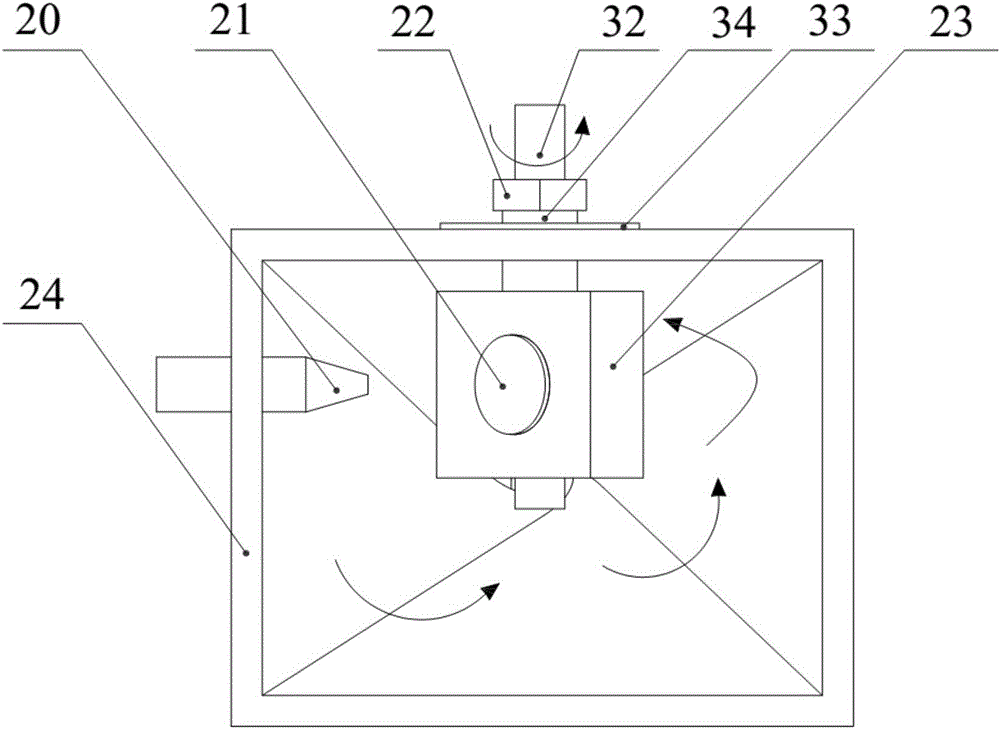

[0036] like figure 1 As shown, the present invention includes a slurry kettle 35, a liquid phase circulation assembly, a gas phase assembly, a solid phase assembly, and a test pipe section 24. The inside of the slurry kettle 35 is filled with a test medium 5, and the bottom of the slurry kettle 35 is provided with a motor 1 and a motor 1 The end is connected with one end of the stirring shaft through a coupling 2, and the other end of the stirring shaft is equipped with a stirring blade 4 for stirring the test medium 5 in the slurry kettle 35, and the rotation center axis of the stirring shaft and the cylinder of the slurry kettle 35 rotate The central axes coincide, and the other end of the stirring shaft is circumferentially arranged with 2n-1 (n=2 or 3) stirring blades 4, such as 3 or 5 stirring blades, and the stirring blades 4 are driven by the rotation of the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com