Conveying device for heating furnace

A technology of conveying device and heating furnace, applied in lighting and heating equipment, furnace, charge and other directions, can solve the problems of surface damage of steel pipes, collision of steel pipes with each other, large impact, etc., and achieve uniform heating state, stable conveying rate, and conveying rate. and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

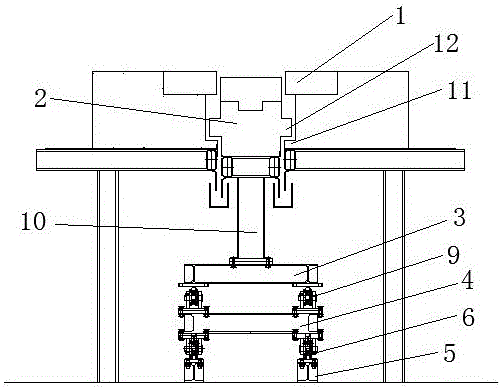

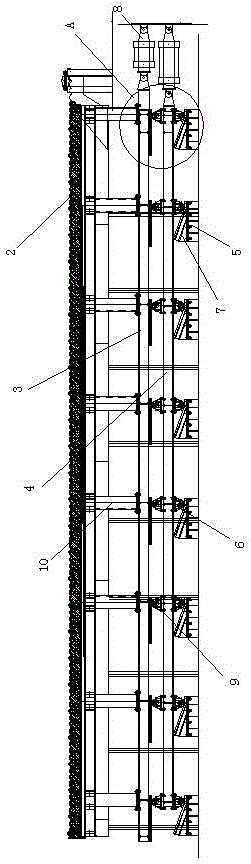

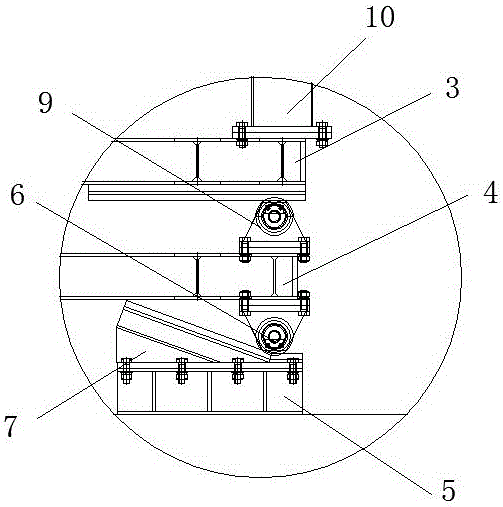

[0022] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention includes a supporting table 1 and a conveying table 2, a first moving rack 3, and a second moving rack 4 arranged parallel to each other. The conveying table 2 is fixed above the first moving rack 3, and the first moving rack 3 is slidably arranged above the second moving frame 4, there are more than three linearly aligned sliding seats 5 arranged under the second moving frame 4, and the bottom of the second moving frame 4 is provided with more than three first sliding seats that cooperate with the sliding seats 5. A pulley 6, the sliding seat 5 is provided with an inclined platform 7, and the inclined surface of the inclined platform 7 is set toward the first pulley 6, and the ends of the first moving frame 3 and the second moving frame 4 are connected with a telescopic cylinder 8 for pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com