Bearing pad oil supply device with servo valve

A technology of oil supply device and servo valve, which is applied in the direction of engine lubrication, lubricating oil control valve, engine components, etc., which can solve the problems of inability to meet the requirements of working condition adjustment, the maintenance and operation burden of power plants, and the drift of the setting value of the oil pump outlet flow limiting valve and other issues, to achieve the effect of ensuring reliability, ensuring operation requirements, and preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

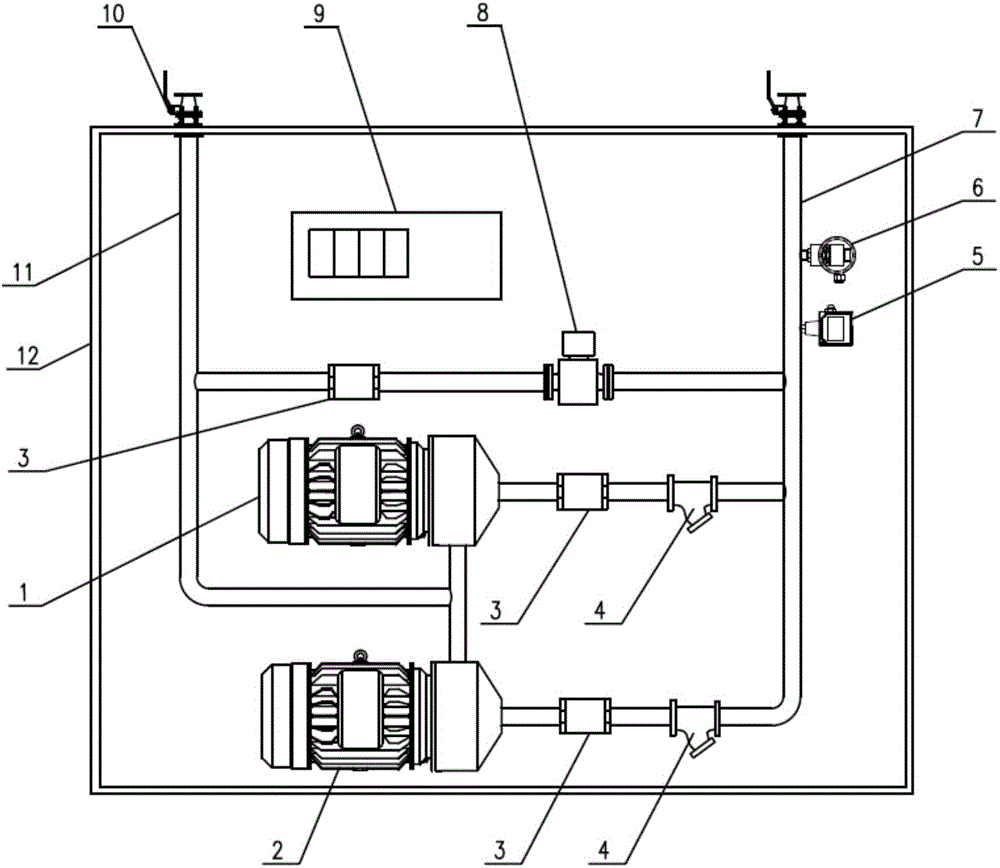

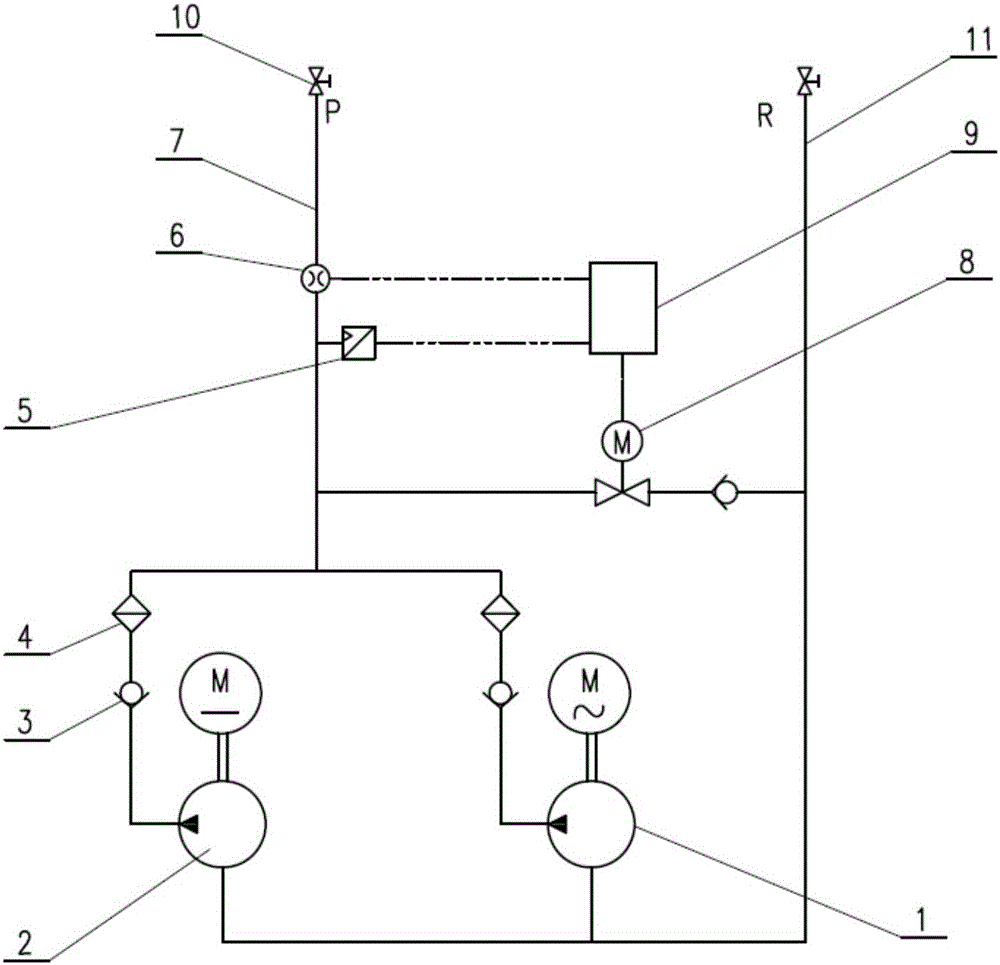

[0013] According to attached figure 1 As shown, all the components of a bearing pad oil supply device with a servo valve are installed in a cabinet body 13 with a closed frame structure, which is helpful for installation and maintenance. The bearing pad oil supply device adopts AC motor oil pump unit 1 and DC oil pump unit 2 as In the main and backup units, the AC motor is given priority in normal application, and the DC motor is started in the case of maintenance or AC failure. Since the initial stage of unit startup requires high pressure to inject lubricating oil into the gap between bearing bushes, the oil port of servo valve 8 will be controlled by The fully open position is gradually closed to prevent the oil pump from starting under pressure to cause impact on the motor and power supply. During the pressure building operation stage, the programmable controller 9 calculates the corresponding oil delivery volume according to the design value and the pressure curve. Feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com