Screw rotor with variable pitch and variable meshing clearance

A technology of variable meshing clearance and variable pitch, applied in rotary piston pumps, rotary piston machines, rotary piston/oscillating piston pump components, etc. Unstable, liquid hammer and other problems, to solve the pressure surge or even liquid hammer, increase safety and reliability, and improve volumetric efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

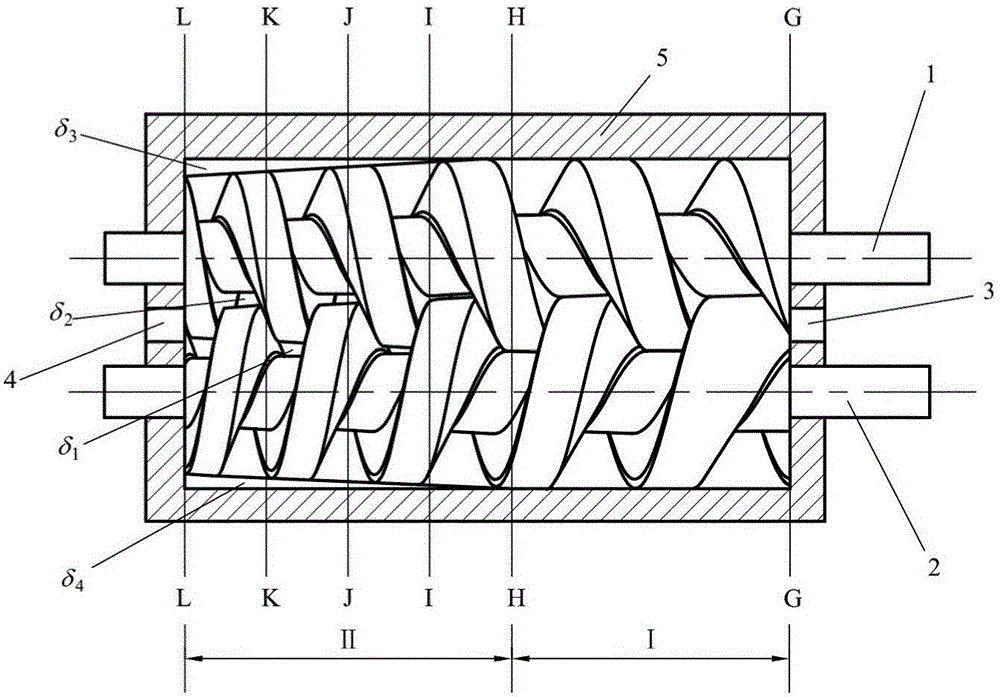

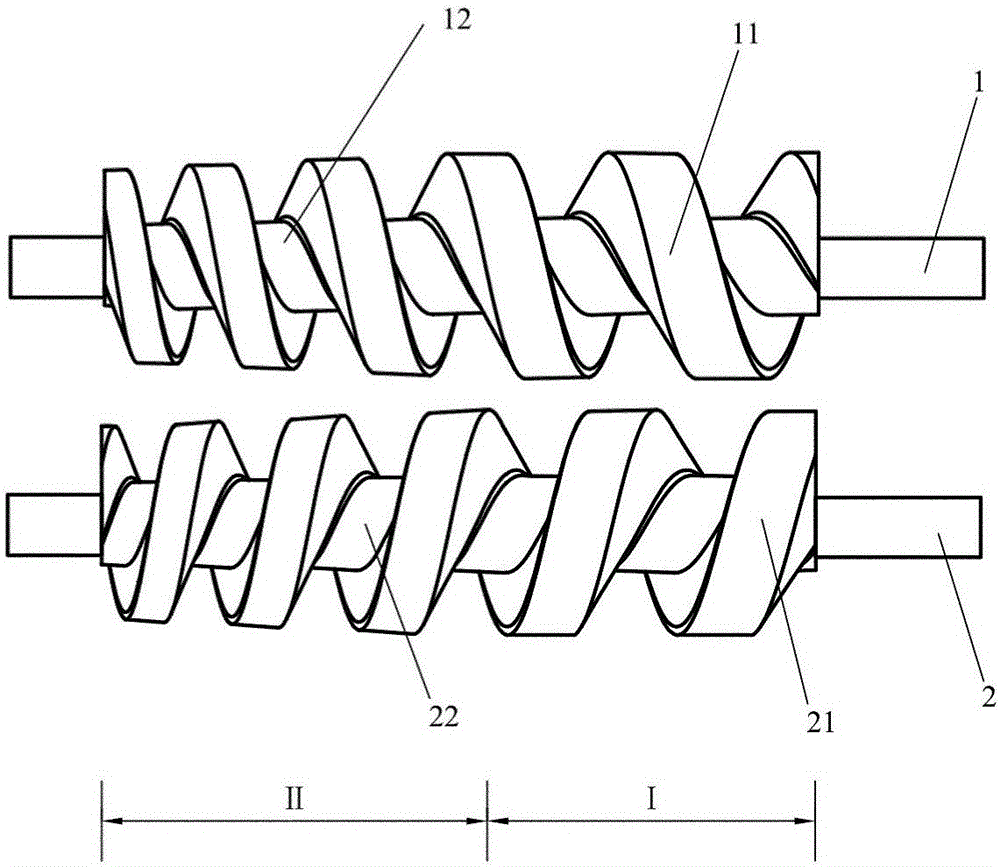

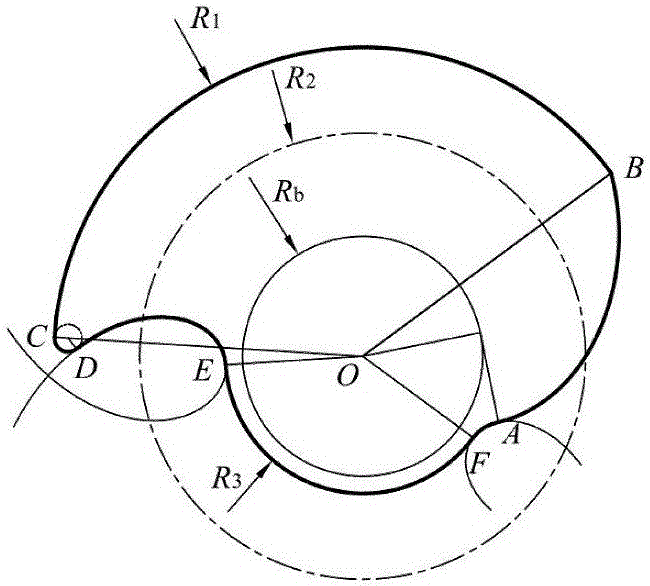

[0040] Such as figure 1 As shown, it is the meshing diagram of the screw rotor with variable pitch and variable meshing gap in operation; the right-handed screw rotor (1) and the left-handed screw rotor (2) that mesh with each other during work are both variable-pitch screw rotors, in the shell ( 5) to achieve meshing; the screw rotor is composed of a suction section (I) and a compression discharge section (II), and the two sections are smoothly connected; the suction section (I) of the screw rotor is connected to the suction port (3), and the compression discharge section ( Ⅱ) Connect the discharge port (4); the suction section (I) of the two screw rotors has no meshing clearance; the compression discharge section (II) of the two screw rotors has meshing clearance and is conical, the closer to the discharge section At the exit (4), the outer diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com