Programmed type sewage lifting pump station

A technology for lifting sewage and lifting pumps, which is applied to waterway systems, water supply devices, and drainage structures, etc. Increase fluidity and avoid the effect of accumulation and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

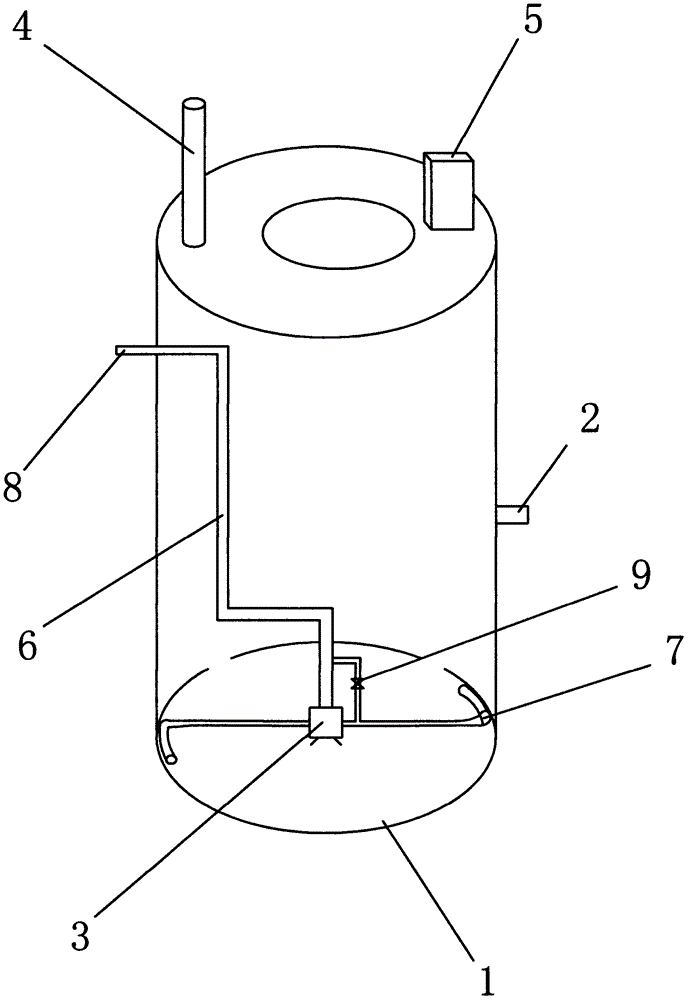

[0010] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0011] refer to figure 1 As shown, the program-controlled sewage lifting pump station of the present invention includes a cylinder body 1, the side wall of the cylinder body 1 is provided with a water inlet 2 and a water outlet 8, the bottom of the cylinder body 1 is provided with a lifting pump 3, and the top of the cylinder body 1 is provided with There is an exhaust pipe 4 and a control box 5. The control box is equipped with PLC control circuit boards and switches and other components. The lift pump 3 is connected to the water outlet 8 through the drain pipe 6. Of course, since the lift pump is relatively mature equipment, its specific The structure has multiple, also can have multiple changes, and the structure of the present invention is all applicable.

[0012] The present invention also includes a sewage flushing pipe 7, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com