Cordierite honeycomb ceramic and preparation method thereof

A cordierite honeycomb and ceramic technology, which is applied in the field of ceramic processing, can solve the problems of high firing temperature, complicated manufacturing process, and high cost, and achieve the effects of low firing temperature, low cost, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

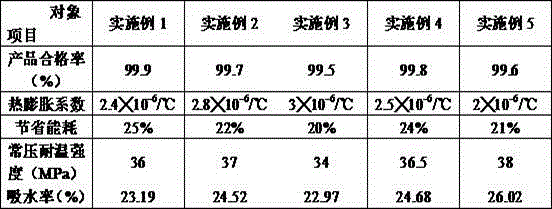

Examples

Embodiment 1

[0022] A kind of cordierite honeycomb ceramics is composed of base material and additive carboxymethyl cellulose, and the base material is chlorite MgO·Al 2 o 3 • 3SiO2 2 • 4H 2 O, clay Al 2 o 3 • 2SiO2 2 • 2H 2 O and quartz SiO 2 ; The weight percent of chlorite, clay and quartz in the base material is: chlorite 40%, clay 50%, quartz 10%; Main oxide in the described base material is: MgO, Al 2 o 3 , SiO 2 , the weight percentage of the main oxide is: MgO10%, Al 2 o 3 40%, SiO 2 50%.

[0023] The specific steps of the preparation method are as follows:

[0024] S1. Selection of raw materials: crush the hard base material chlorite, clay and quartz according to the formula, and then pass the crushed base material into the iron removal machine to remove the iron impurity ferric oxide;

[0025] S2, batching: batching the base material after step S1 according to the weight ratio of base material and additive carboxymethyl cellulose is 99%:1%, to form ceramic raw mater...

Embodiment 2

[0031] A kind of cordierite honeycomb ceramics is composed of base material and additive carboxymethyl cellulose, and the base material is chlorite MgO·Al 2 o 3 • 3SiO2 2 • 4H 2 O, clay Al 2 o 3 • 2SiO2 2 • 2H 2 O and quartz SiO 2 ; The percentage by weight of chlorite, clay and quartz in the base material is: 45% of chlorite, 50% of clay, 5% of quartz; in the base material, the main oxides are: MgO, Al 2 o 3 , SiO 2 , the weight percentage of main oxides is: MgO 14%, Al 2 o 3 31.5%, SiO 2 54.5%.

[0032] The specific steps of the preparation method are as follows:

[0033] S1. Selection of raw materials: crush the hard base material chlorite, clay and quartz according to the formula, and then pass the crushed base material into the iron removal machine to remove the iron impurity ferric oxide;

[0034] S2, batching: batching the base material after step S1 according to the weight ratio of base material and additive carboxymethyl cellulose is 99.5%:0.5%, to form ...

Embodiment 3

[0040] A kind of cordierite honeycomb ceramics is composed of base material and additive carboxymethyl cellulose, and the base material is chlorite MgO·Al 2 o 3 • 3SiO2 2 • 4H 2 O, clay Al 2 o 3 • 2SiO2 2 • 2H 2 O and quartz SiO 2 ; The weight percent of chlorite, clay and quartz in the base material is: chlorite 55%, clay 40%, quartz 5%; Main oxide in the described base material is: MgO, Al 2 o 3 , SiO 2 , the weight percentage of the main oxide is: MgO20%, Al 2 o 3 30%, SiO 2 50%.

[0041] The specific steps of the preparation method are as follows:

[0042] S1. Selection of raw materials: crush the hard base material chlorite, clay and quartz according to the formula, and then pass the crushed base material into the iron removal machine to remove the iron impurity ferric oxide;

[0043] S2, batching: batching the base material after step S1 according to the weight ratio of base material and additive carboxymethyl cellulose is 99.9%:0.1%, to form ceramic raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com