Dual-body electric grain discharge device

A grain unloading device, electric technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of large area occupation, single function, high cost, etc., and achieve the effect of compact and simplified structure, reasonable structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (Example 1, two-body electric grain unloading device)

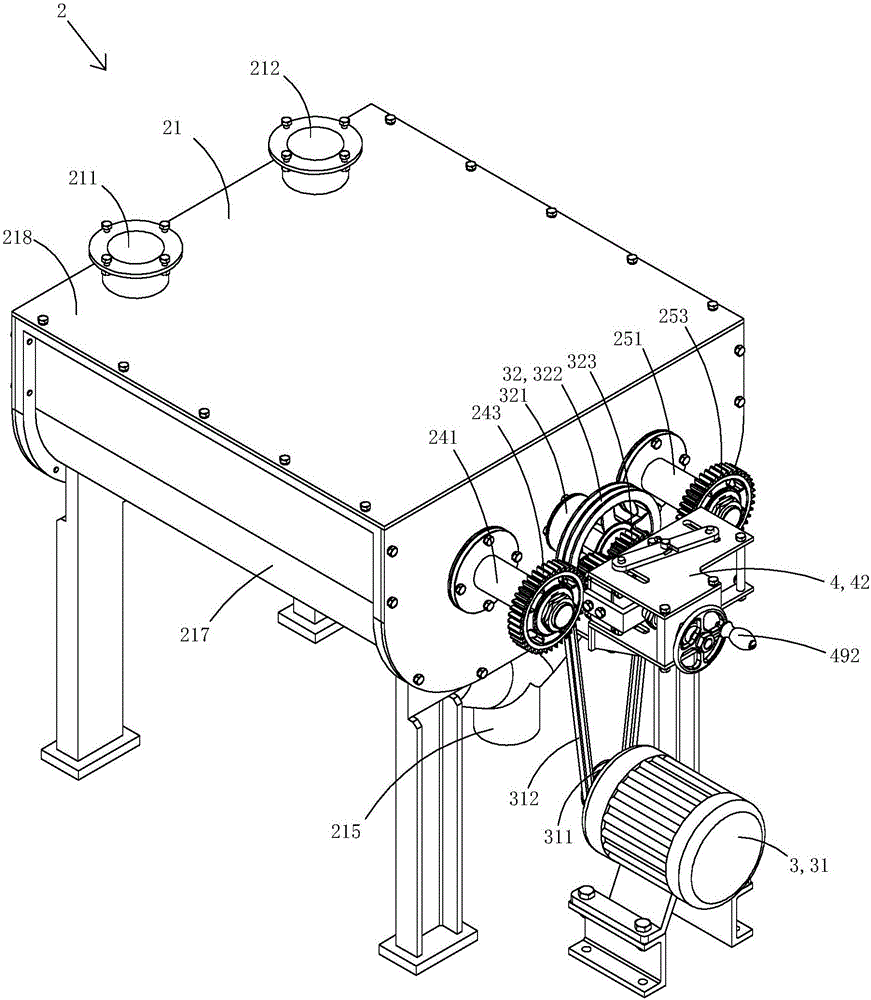

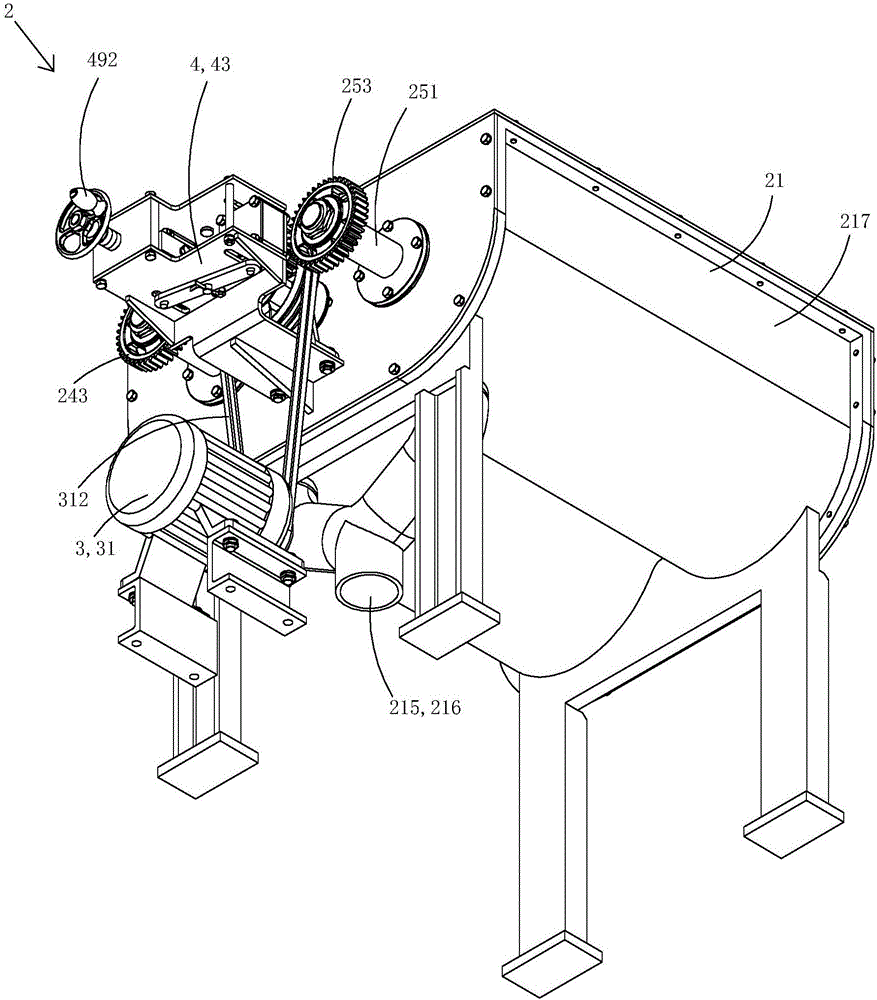

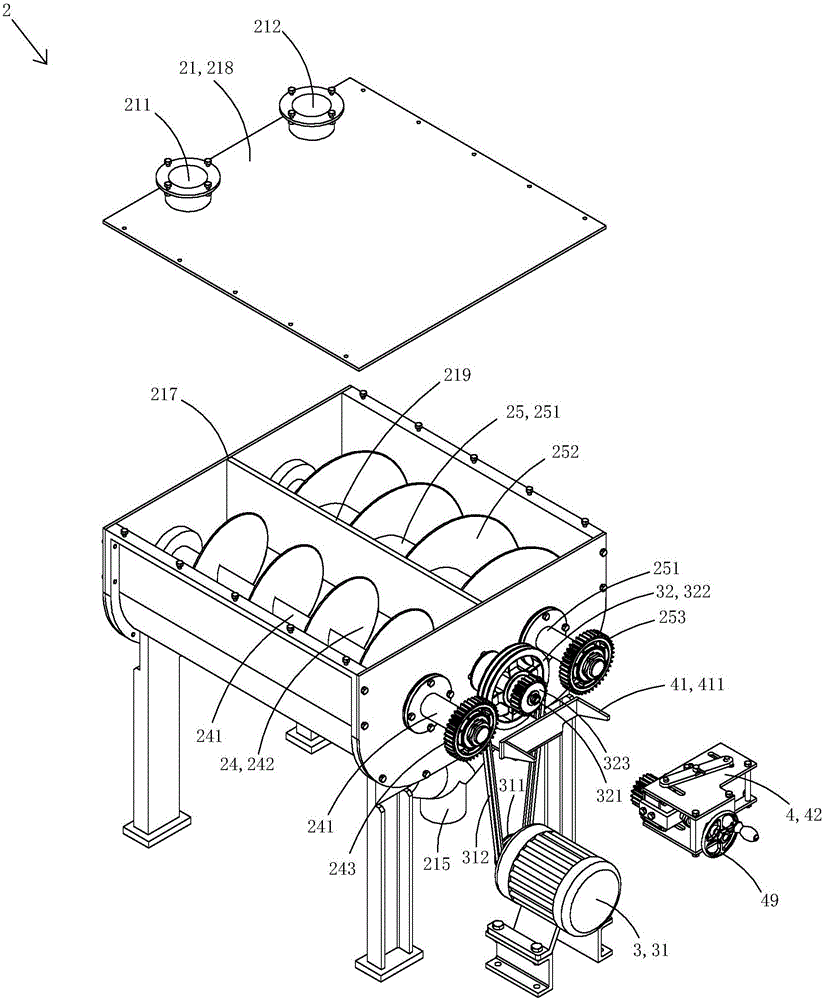

[0036] Figure 1 to Figure 10 One specific embodiment of the invention is shown.

[0037] This embodiment is a two-body electric grain unloading device, see Figure 1 to Figure 10 As shown, the electric grain unloading device 2 includes a box body 21 with a first grain unloading channel and a second grain unloading channel inside, a first auger 24 arranged in the first grain unloading channel, and a first auger 24 arranged in the second grain unloading channel The second auger 25 inside, and the driving device 3 for driving the first auger and the second auger to rotate.

[0038] The top of the box is provided with a first grain inlet 211 and a second grain inlet 212, and the bottom of the box is provided with a first grain outlet and a second grain outlet; the first grain inlet serves as the first grain unloading channel The import of the first grain outlet is used as the export of the first grain unloading cha...

Embodiment 2

[0068] (Example 2, two-body electric grain unloading device)

[0069] This embodiment is basically the same as Embodiment 1, the difference is that the driving mechanism 49 in this embodiment no longer uses a manual crank wheel, but a pulley is set on the driving screw 491, and a pulley is set on the frame body to drive the The reciprocating motor of the pulley drives the driving screw to reciprocate through the reciprocating rotation of the motor, so that this embodiment has an electric switching function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com