Production method for iron furnace slag light building block

A production method, iron slag technology, applied in the field of iron slag light-duty block production, can solve the problems of high cost of design building mechanics, unit volume weight of masonry, large amount of steel, etc., to achieve small footprint and low production cost Low, weight-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Raw material formula: iron slag: 15%, chimney ash 15%, perlite 20%, 425# cement 50% to form a dry mix.

[0054] Per ton of dry mix: 2.4 cubic meters of polystyrene particles.

[0055] Mixing per ton of dry mix: add water at 24%.

[0056] 1.5% of various additives include: 1.5kg of hydroxypropyl methylcellulose, 0.4kg of dispersible latex powder, 9.2kg of early strength agent, 480ml of water reducing agent, and 800ml of air-entraining agent.

Embodiment 2

[0058] Raw material formula: iron slag: 20%, chimney ash 10%, perlite 15%, 425# cement 55% to form a dry mix.

[0059] Per ton of dry mix: 2.6 cubic meters of polystyrene particles.

[0060] Mixing per ton of dry mix: add water at 26%.

[0061] Various additives 2% include: 1.5kg of hydroxypropyl methylcellulose, 0.5kg of dispersible latex powder, 10kg of early strength agent, 500ml of water reducing agent, and 900ml of air-entraining agent.

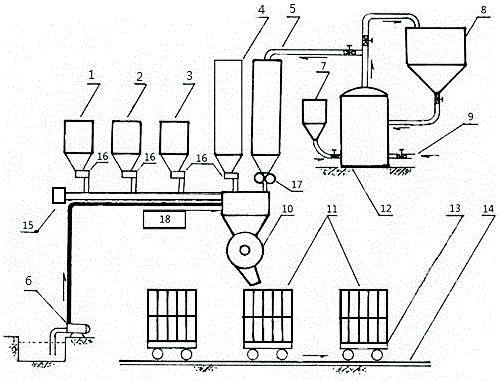

[0062] Referring to the accompanying drawings, the production system includes: iron slag hopper 1, chimney ash hopper 2, perlite hopper 3, cement silo 4, polystyrene particle silo 5, water pump 6, polystyrene raw material silo 7, polystyrene primary Expansion silo 8, steam pipe 9, mixer 10, mold combination 11, polystyrene particle extruder 12, mold car 13, light rail 14, scraper conveyor 15, electronic scale 16, volumetric meter 17, additive storehouse 18.

[0063] The outlets of the iron slag hopper 1, the chimney ash hopper 2, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com