Anti-bite integrated type cable

A cable and shape technology, applied in the direction of insulating cables, cables, conductors, etc., can solve the problems of poor flexibility of cable sheath materials, insufficient creep resistance, insufficient wear resistance, and poor heat dissipation performance of cable outer sheaths. It achieves the effect of convenient overall burying, high wear resistance and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

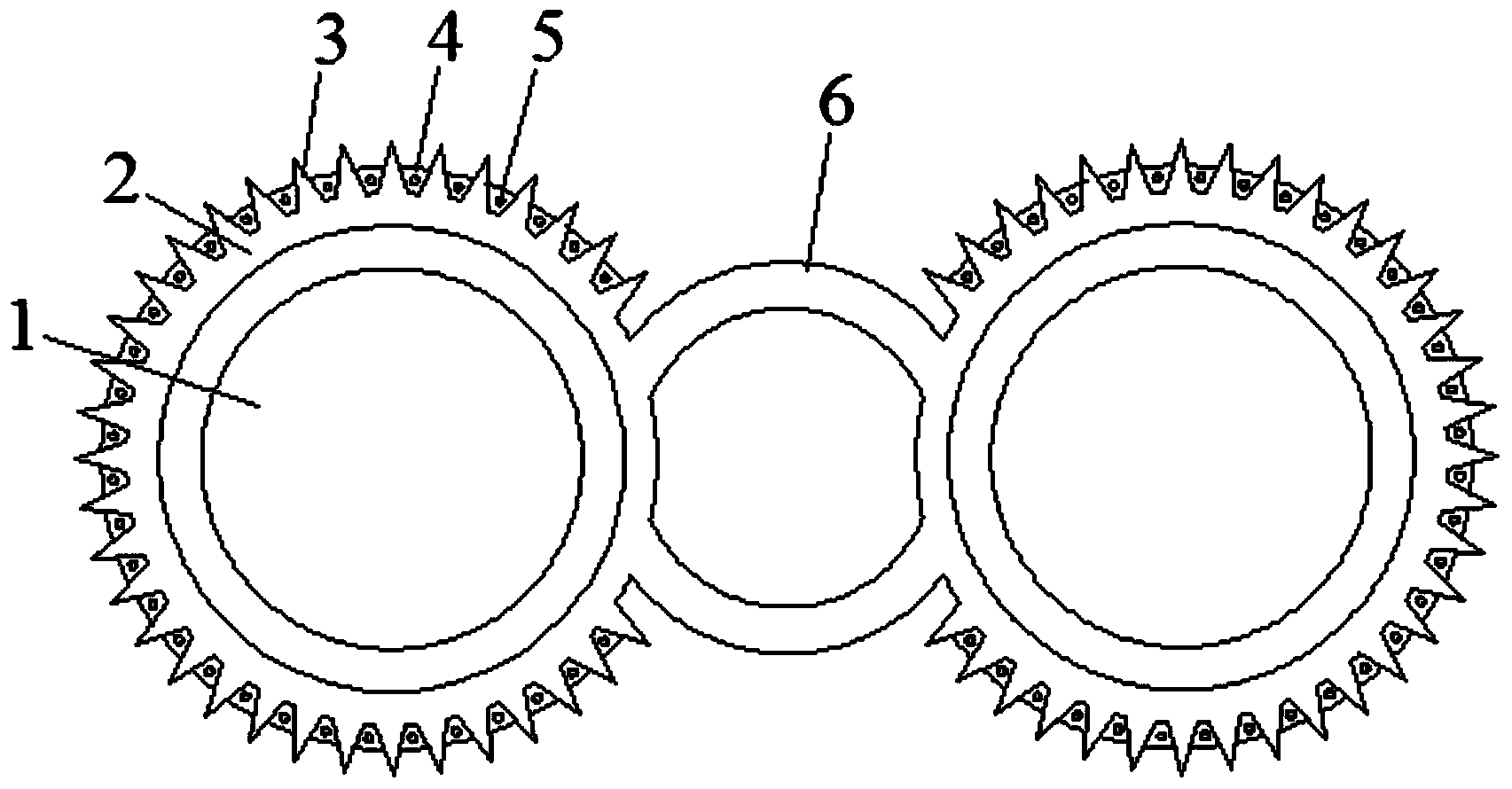

[0018] see figure 1 , an anti-bite conjoined cable, including two cables, the two cables respectively include a cable core 1 and a sheath 2 covering the outside of the cable core 1, and the outer periphery of the sheath 2 has an integrally formed multiple A spiky protrusion 3, there is a gap between two adjacent spiky protrusions, and a connecting rib 4 is integrally connected between the adjacent two spiky protrusions, the connecting rib 4 is respectively provided with an opening 5, two There is an insulating ring 6 integrally connected between the sheaths 2 of the cables.

[0019] In the present invention, the cable cores 1 of the two cables respectively include one conductor or multiple conductors twisted together. The material of sheath 2 is made of the following raw materials by weight (kg): polyvinyl chloride resin 70, polypropylene 20, polydicyclopentadiene 12, dioctyl phthalate 10, di-n-butyl sebacate 8, Acetylene carbon black 16, penta(isooctyl mercaptoacetate) anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com