Laser drilling waste collecting mechanism

A laser drilling machine and waste collection technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of damage to the optical system, waste material inhalation, poor safety, etc., to ensure normal operation, cleanliness, and reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

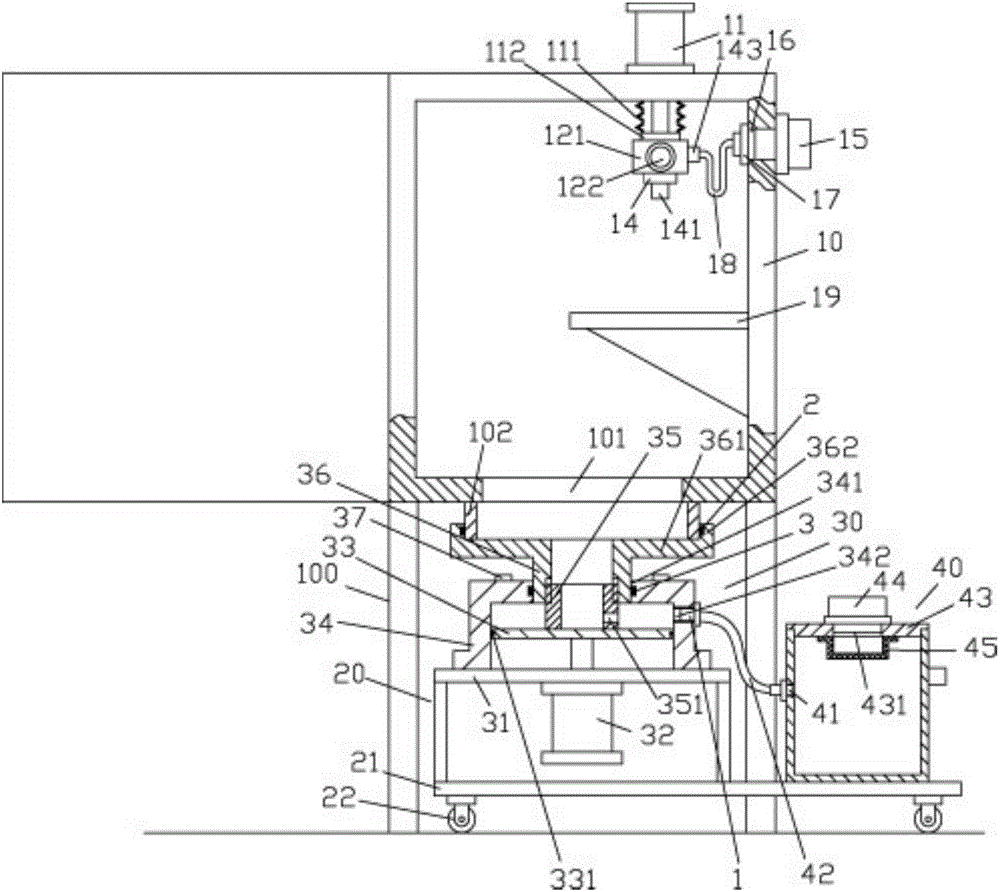

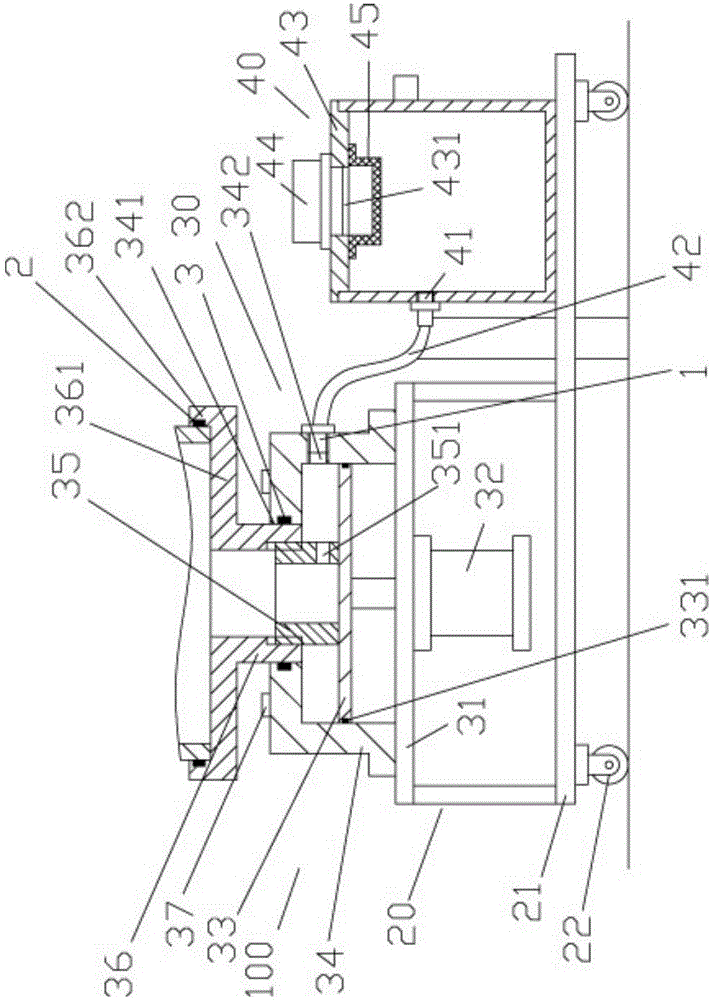

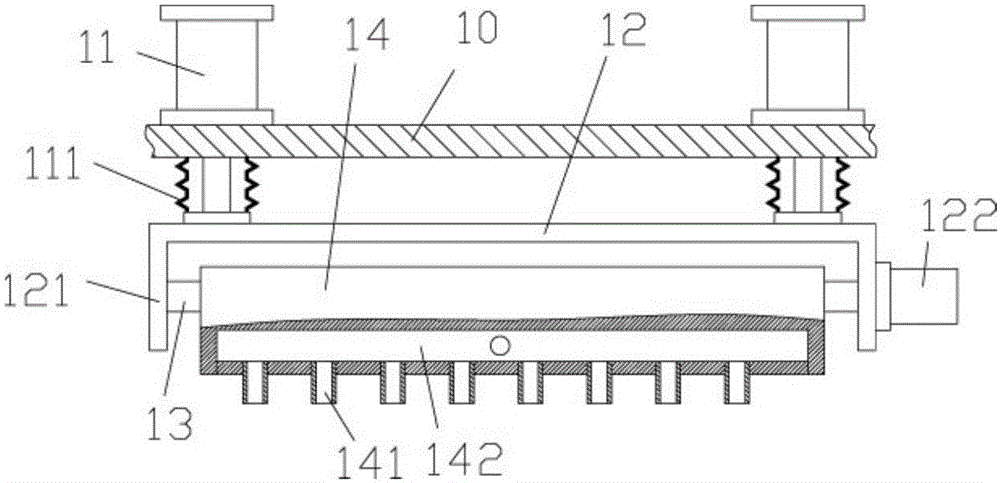

[0028] Examples, see e.g. Figure 1 to Figure 3 As shown, a laser drilling waste collection mechanism includes a laser drilling frame 100, the upper part of the laser drilling frame 100 is a processing box 10, and at least two telescopic cylinders are fixed on the top plate of the processing box 10 11. The push rod of the telescopic cylinder 11 passes vertically downward through the top plate of the processing box 10 and is fixed with a rotating connecting frame 12. The rotating rod 13 is under the rotating connecting frame 12, and the two ends of the rotating rod 13 are hinged on the rotating connecting frame. On the vertical plates 121 that both sides of 12 have, on the outer wall of one of the vertical plates 121, a rotation adjustment motor 122 is fixed, and the output shaft of the rotation adjustment motor 122 is a spline shaft, and the spline shaft is sleeved on the rotating rod 13 In the spline hole that one end of the blower has, the blowing box body 14 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com