Extrusion needle point and perforating needle

A technology for extruding needles and needle tips, which is applied in the direction of metal extrusion mandrels, etc., and can solve the problems of shortening the length of seamless pipes, complicated operations, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

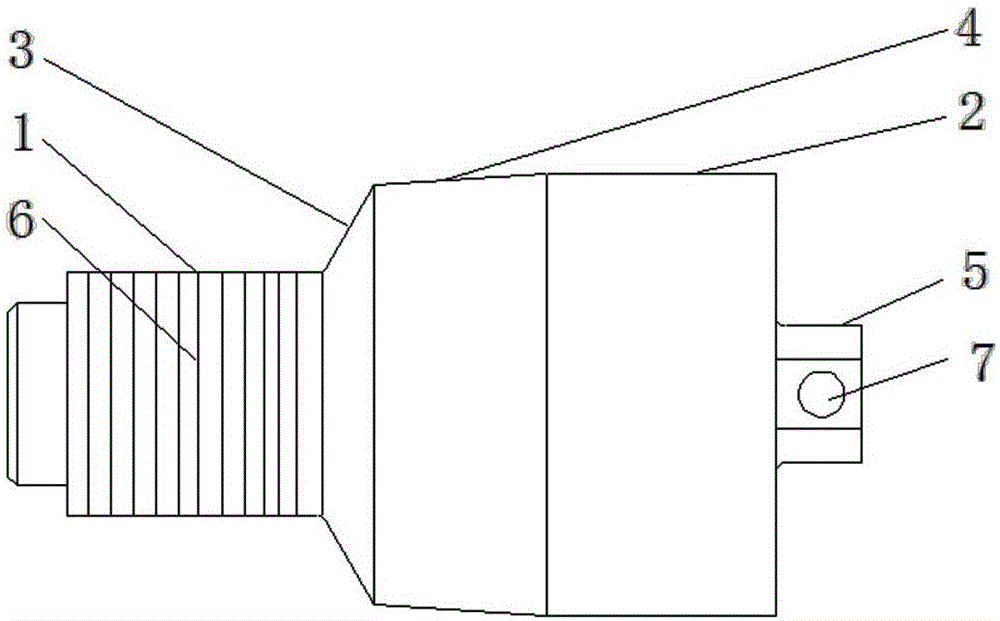

[0018] The core of this specific embodiment is to provide an extruding needle point, which can produce a seamless pipe with an inner hole size larger than the specification of the extruding needle on the premise of satisfying the fixed size length, which solves the problem of the existing technology. in the problem.

[0019] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

[0020] The extruding needle tip provided in this specific embodiment includes: a fixed section 1 , a working section 2 , and a tapered section 3 . Among them, the fixed section 1 is used to connect with the extrusion needle; the working section 2 is used to extrude the seamless pipe, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com