Rain curtain desulfurization spray tower

A spray tower and rain curtain technology, applied in calcium/strontium/barium sulfate, separation methods, dispersed particle separation, etc., can solve the problems of high energy consumption, low energy consumption, easy nozzle blockage, etc., and reduce operation Low cost, low energy consumption, and the effect of solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

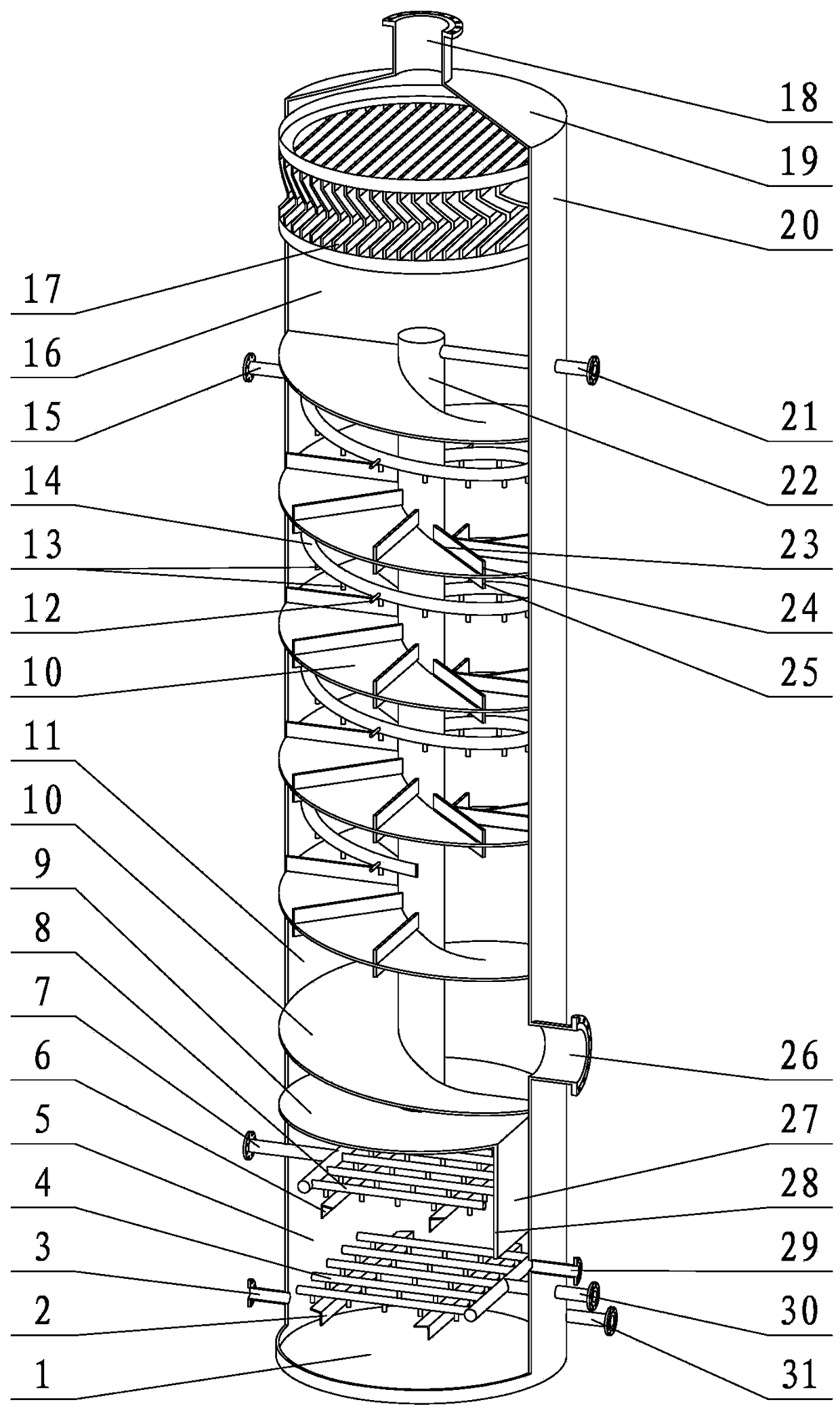

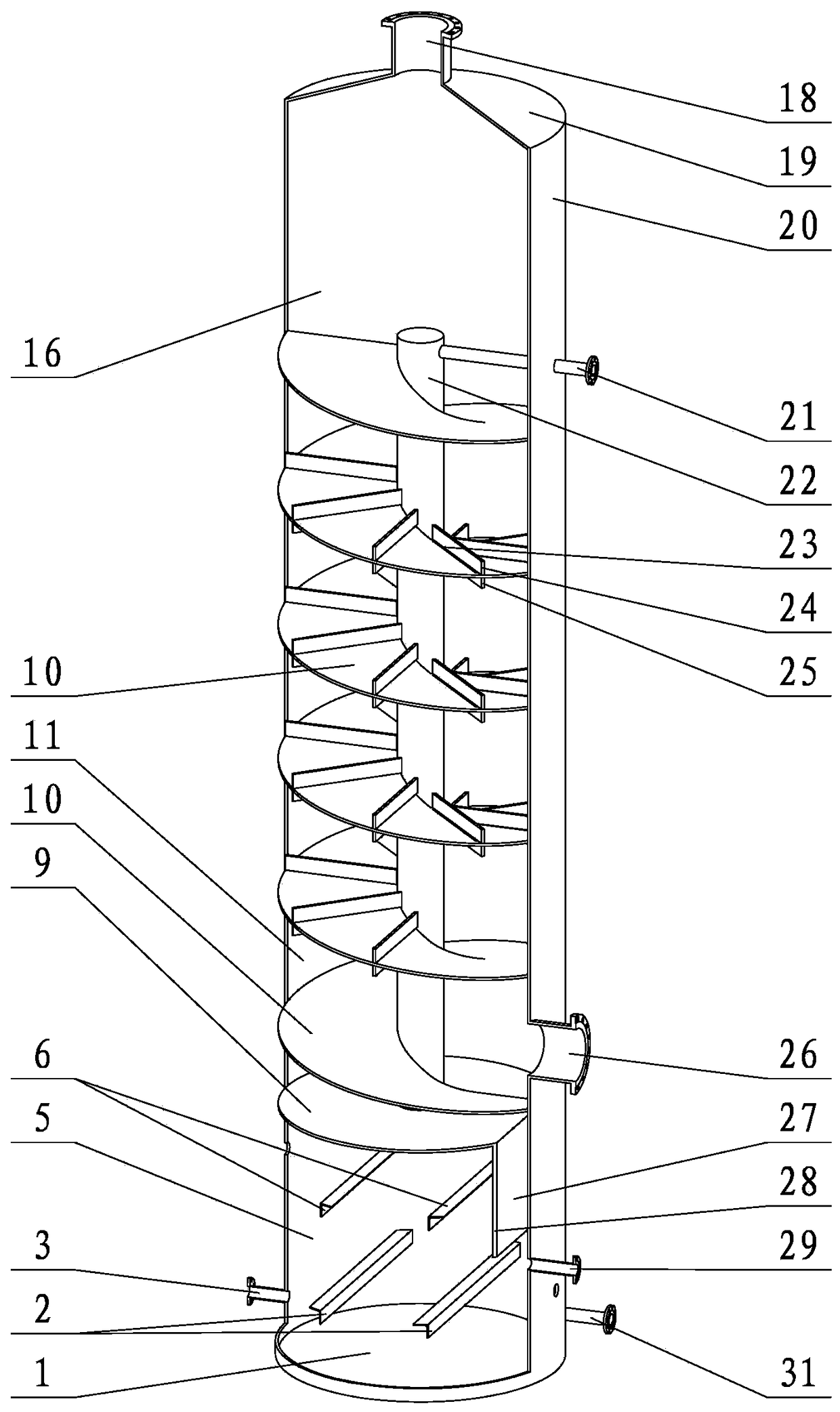

[0027] The present invention is further described below in conjunction with accompanying drawing.

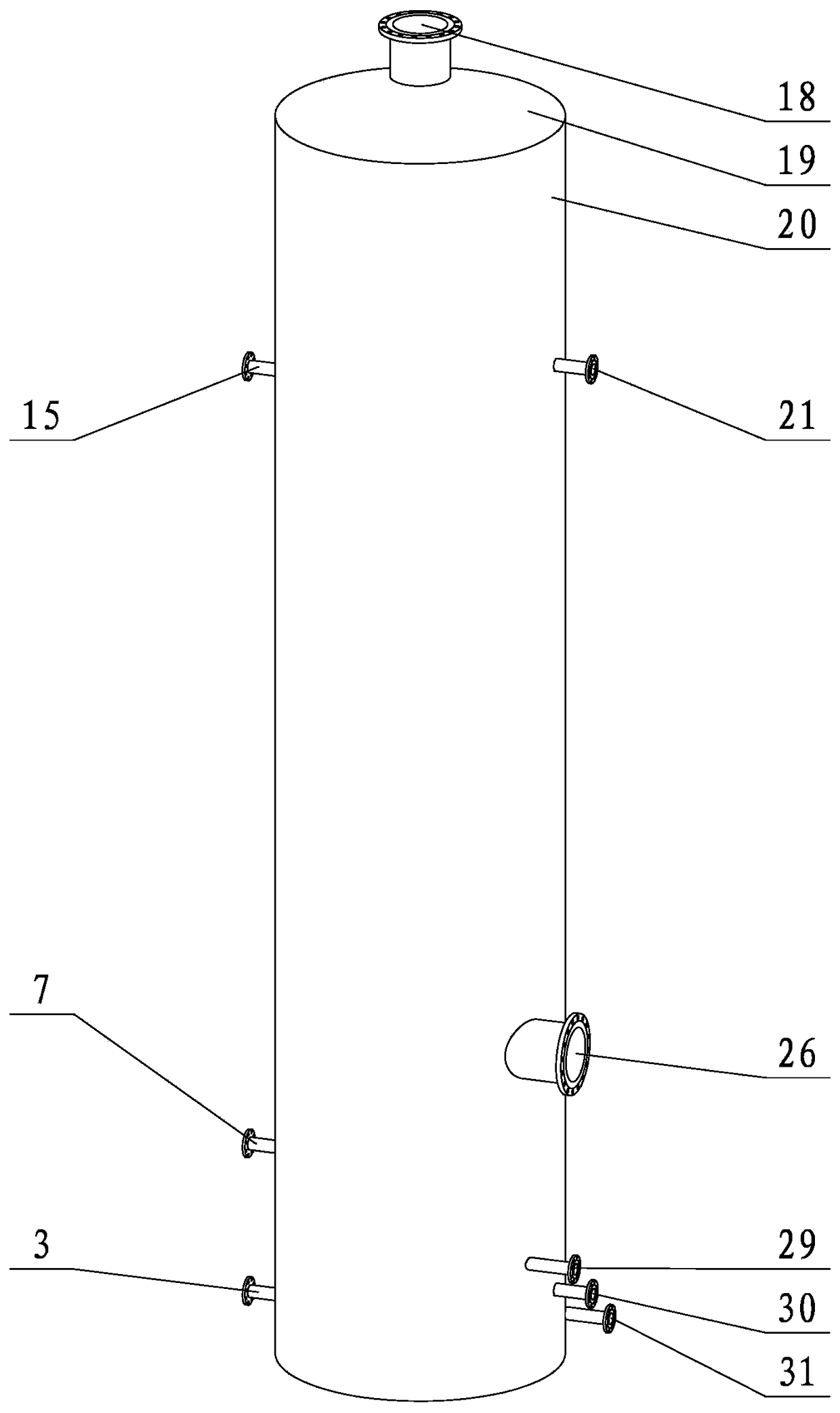

[0028] refer to Figure 1 to Figure 13 , The rain curtain desulfurization spray tower includes a tank body, a pulse stirring water distribution pipe 4, an oxidation cloth air pipe 8, a partition part, a central exhaust pipe part, a spiral tray part, a spray pipe part, and a demister 17. The inner cavity of the tank is sequentially installed with a pulse stirring water distribution pipe 4, an oxidation distribution air pipe 8, a partition part, a central exhaust pipe part, a spiral tray part, a spray pipe part, and a demister 17 from bottom to top.

[0029] The tank body is welded together by the tank body bottom plate 1, the tank body cylinder body 20, the tank body top plate 19, and the flue gas outlet pipe 18 sequentially from bottom to top. The tank body 20 is cylindrical.

[0030] The bottom of the radially inner side of the tank body 20 is sequentially welded with a lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com