Method for data conversion between stress analysis and three-dimensional models in pipeline design

A stress analysis and three-dimensional model technology, applied in the direction of electrical digital data processing, computer-aided design, special data processing applications, etc., can solve problems such as wasting time, increasing the error rate of calculation data input, reducing the quality of finished product design, etc., to achieve multiple solutions The effects of professional collaboration, reduction of repeated input, and improvement of design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

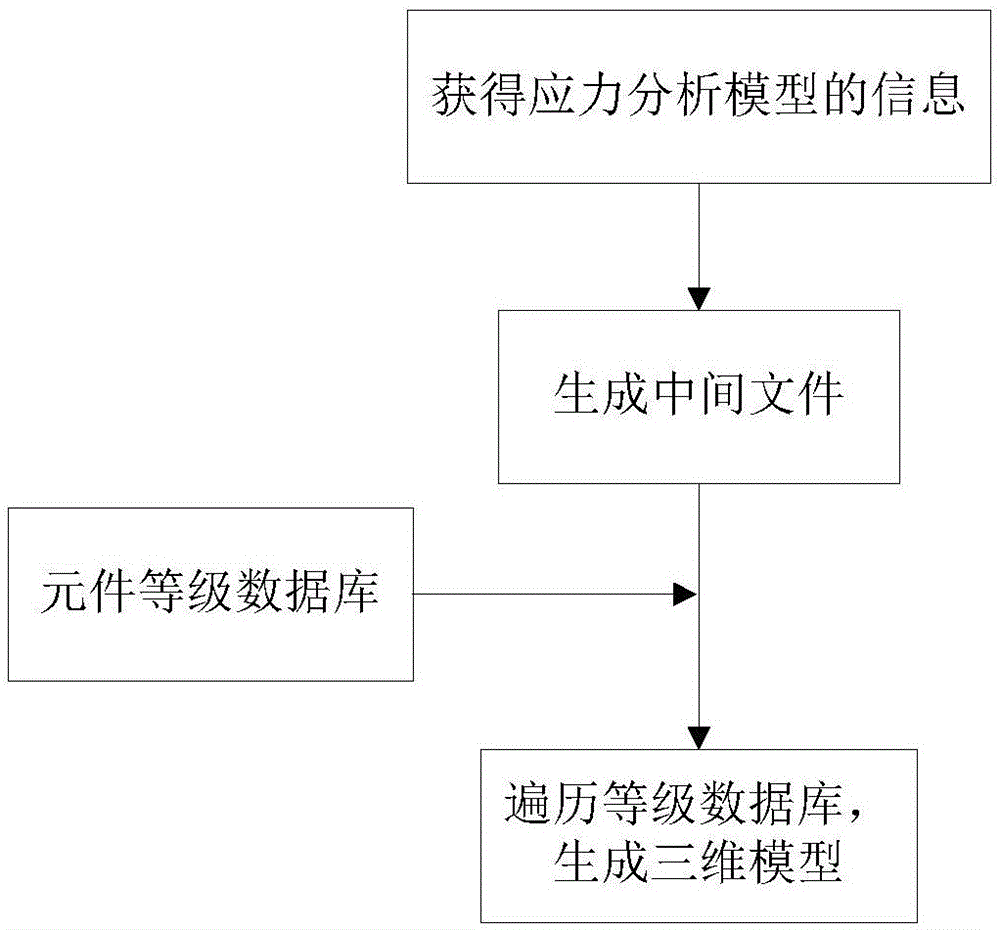

[0056] Such as figure 1 The data conversion method from stress analysis to three-dimensional model in the pipeline design of the present invention is shown, taking GLIF stress analysis software and PDMS three-dimensional model software as examples, the steps include:

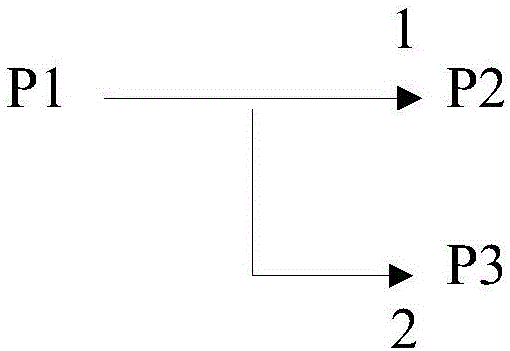

[0057] A. Establish a stress analysis model that meets the stress requirements. By traversing the stress analysis model, obtain the pipeline topology, the spatial coordinates and interrelationships of each component, and component parameters including various levels of information. The obtained component parameters include multiple parts, first of all the grades of pipes, hangers and false tees that appear in the corresponding pipelines, and each grade is followed by temperature, pressure, material and corresponding in PDMS software Attributes such as class names. Then list all the branches in the pipeline and the related properties of all the pipe fittings under the branch in sequence according to the order of...

Embodiment 2

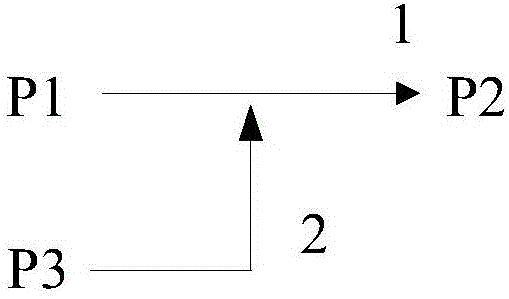

[0069] Such as Figure 9 In the shown pipeline design of the present invention, the data conversion method from three-dimensional model to stress analysis is taken as an example with PDMS three-dimensional model software and GLIF stress analysis software, and the steps include:

[0070] A. Use the grade name of the component as an index to establish a component grade database containing the parameters of each component. Different component grade names correspond to the corresponding data in the component grade database. The component grade database includes pipe wall thickness and outer diameter, pipe fitting weight, elbow bending radius and wall thickness, tee stress enhancement coefficient, large and small head outer diameter / small head outer diameter, pipe insulation under the corresponding grade name in the component grade database. Thickness, insulation layer bulk density and other parameter properties.

[0071] B. Establish the pipeline layout of the three-dimensional m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Bending radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com