Portable multi-directional steel mesh spacing locator

A kind of steel mesh, portable technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of poor spacing positioning effect, complex processing, layout, narrow applicable surface, etc., to achieve assembly, disassembly and positioning. The steps are simple and clear, the cost is low, and the effect is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

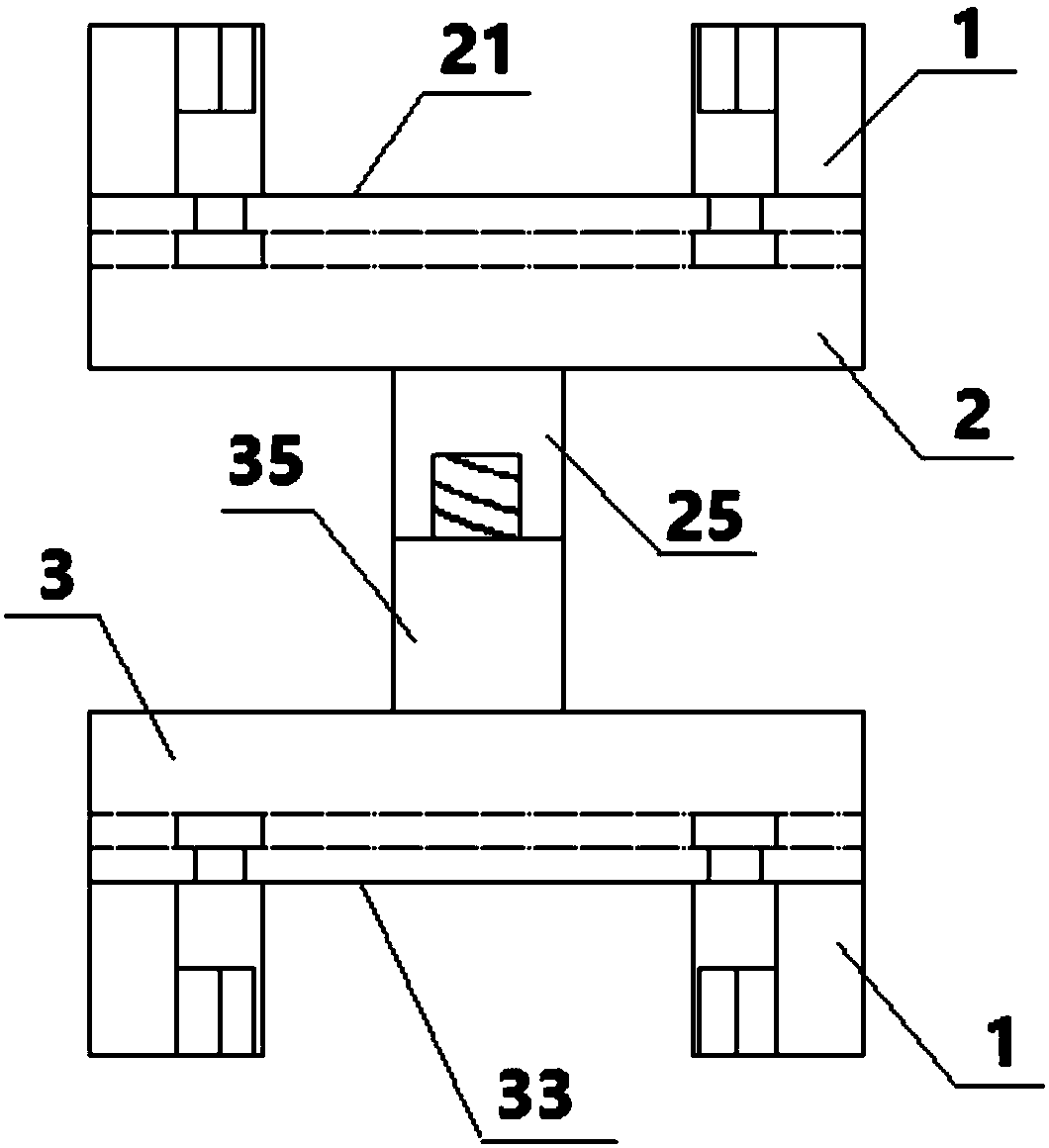

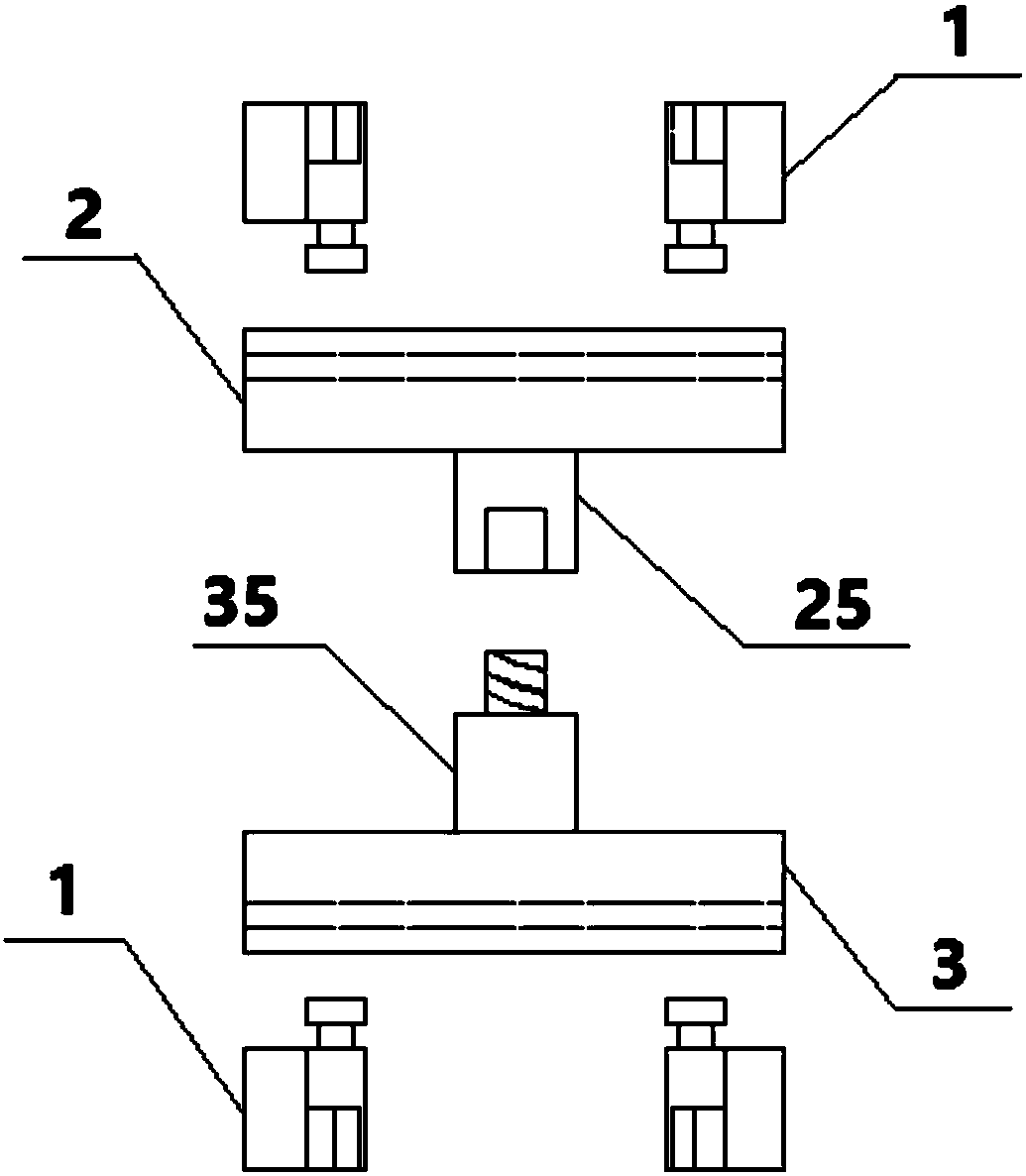

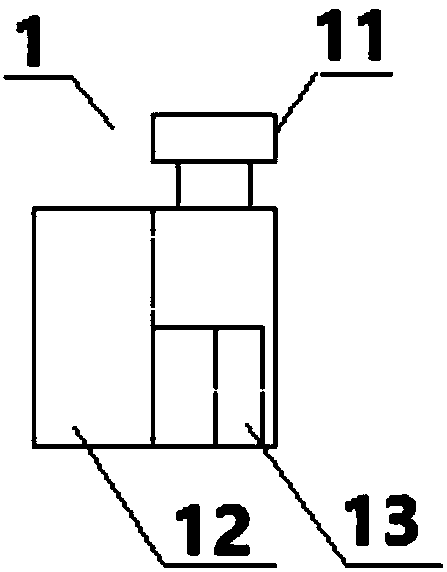

[0061] Such as Figure 1-2 As shown, it includes a positioning clamp 1, a hole connection plate 2 and a head connection plate 3;

[0062] Such as Figure 6-8 As shown, one side of the hole connection plate 2 is the hole connection plate chute surface 21, the hole connection plate chute surface 21 is provided with the hole connection plate chute 22, the hole connection plate chute 22 is in a square and diagonal distribution, the hole connection Disc chute 22 is provided with open notch 221, and the other side of hole connection disc 2 is connection hole surface 23, and connection hole surface 23 is provided with hole connection disc boss 25, and hole connection disc boss 25 is provided with connection hole 24. The connection hole 24 is opened on the top surface of the hole connection plate boss 25, and the inner wall of the connection hole 24 is provided with internal threads (not shown in the figure);

[0063] Such as Figure 9-11 As shown, one side of the head connection p...

Embodiment 2

[0070] Such as Figure 12-13 As shown, it includes a positioning clamp 1, a hole connection plate 2 and a head connection plate 3;

[0071] The positioning and clamping part 1 of this embodiment is also a magnet positioning and clamping part, and its structure is exactly the same as that of the positioning and clamping part in Embodiment 1, and will not be repeated here.

[0072] Such as Figure 14-15 As shown, one side of the hole connection plate 2 is the hole connection plate chute surface 21, the hole connection plate chute surface 21 is provided with the hole connection plate chute 22, the hole connection plate chute 22 is in a square and diagonal distribution, the hole connection The disk chute 22 is provided with an open notch 221, and the other side of the hole connection disk 2 is a connection hole surface 23. In this embodiment, the connection hole 24 is directly arranged in the hole connection disk 2, and the opening of the connection hole 24 is arranged on On the...

Embodiment 3

[0078] Such as Figure 18 As shown, this embodiment is the assembly of the portable multi-directional steel mesh spacer in embodiment 1. The assembly of this embodiment requires a fixing member 6 to fix and position the clamping member 1 .

[0079] The structure of the fixture 6 is as Figure 19 As shown: the fixed part 6 includes a fixed connection plate 61 and four slidable connectors 62; one side of the fixed connection plate 61 is a fixed connection plate chute surface 612, and the fixed connection plate chute surface 612 is provided with a fixed connection plate chute 611 , the chute 611 of the fixed connecting plate is distributed in a square and diagonal, and the chute 611 of the fixed connecting plate is a closed chute; The lower part of the "L"-shaped raised connection part 621 of the sliding connector is provided with a circular slider 622 for the slidable connector, and the circular slider 622 for the slidable connector is arranged in the chute 611 of the fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com