Method for preparing super-amphiphobic aluminum surface

An aluminum surface, super-amphiphobic technology, applied in the direction of metal material coating process, can solve the problems of poor product stability, difficult mass production, poor super-amphiphobic surface stability, etc., to achieve good stability, low cost, anti- Good effect of self-cleaning and anti-impedance cream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing a super amphiphobic aluminum surface, which specifically includes the following steps:

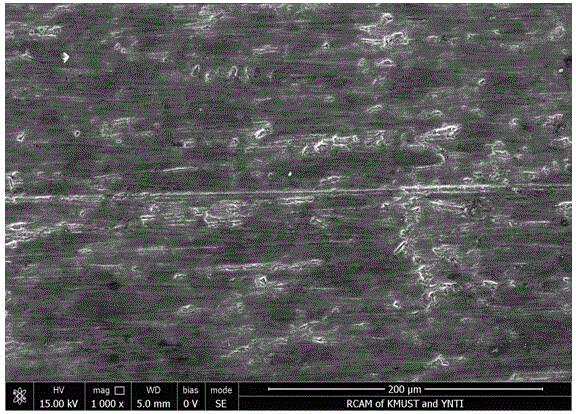

[0023] (1) Pre-treatment: use 400#, 800#, 1200# SiC sandpaper to grind the aluminum sheet horizontally and vertically in order to remove the oxide layer and some oil stains on the surface; after polishing, put the aluminum sheet into ethanol for 30 minutes, and then use ethanol , Ultrasonic cleaning with distilled water for 5 minutes;

[0024] (2) Etching: Put the aluminum sheet into NaCl and CuSO with a concentration of 0.6mol / L 4 Etched in the mixed solution for 6 minutes, and ultrasonically cleaned with distilled water for 10 minutes after etching;

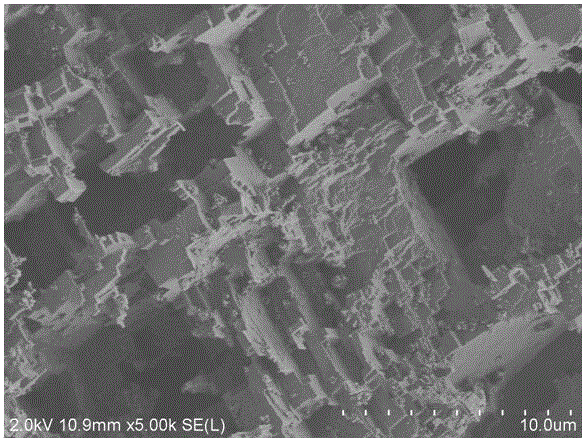

[0025] (3) Construct micro / nano structures: put the cleaned aluminum sheet into boiling distilled water for 7 minutes, and dry at 80°C for 15 minutes after the water bath;

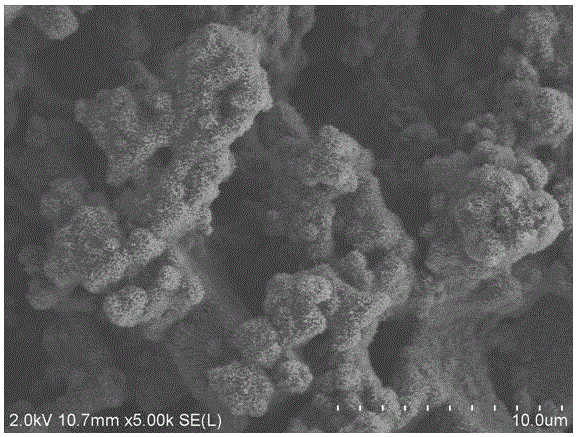

[0026] (4) Low surface energy modification: Soak the dried aluminum sheet in an ethanol solution of 1H, 1H, 2H,...

Embodiment 2

[0028] This embodiment provides a method for preparing a super amphiphobic aluminum surface, which specifically includes the following steps:

[0029] (1) Pre-treatment: Use 800#, 1200#, 1500# SiC sandpaper to polish the aluminum sheet horizontally and longitudinally in turn to remove the oxide layer and some oil stains on the surface. After polishing, soak the aluminum sheet in ethanol for 30 minutes, then ultrasonically clean it with ethanol and distilled water for 5 minutes respectively;

[0030] (2) Etching: Put the aluminum sheet into NaCl and CuSO with a concentration of 0.8mol / L 4 Etched in the mixed solution for 3 minutes, and ultrasonically cleaned with distilled water for 10 minutes after etching;

[0031] (3) Construct micro / nano structures: put the cleaned aluminum sheet into boiling distilled water for 15 minutes, and dry at 80°C for 10 minutes after the water bath;

[0032] (4) Low surface energy modification: Soak the dried aluminum sheet in an ethanol solutio...

Embodiment 3

[0034] This embodiment provides a method for preparing a super amphiphobic aluminum surface, which specifically includes the following steps:

[0035] (1) Pre-treatment: use 1200#, 1500#, 2000# SiC sandpaper to polish the aluminum sheet horizontally and vertically in sequence to remove the oxide layer and some oil stains on the surface. After polishing, soak the aluminum sheet in ethanol for 30 minutes, then ultrasonically clean it with ethanol and distilled water for 5 minutes respectively;

[0036] (2) Etching: Put the aluminum sheet into NaCl and CuSO with a concentration of 1mol / L 4 Etched in the mixed solution for 4 minutes, and ultrasonically cleaned with distilled water for 10 minutes after etching;

[0037] (3) Construct micro / nano structures: put the cleaned aluminum sheet into boiling distilled water for 12 minutes, and dry at 80°C for 10 minutes after the water bath;

[0038] (4) Low surface energy modification: Soak the dried aluminum sheet in an ethanol solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com