DOPO-modified cyclophosphazene fire retardant and preparation and application thereof

A DOPO-CH2OH, flame retardant technology, applied in the direction of flame retardant fibers, textiles and papermaking, chemical instruments and methods, etc., can solve the problem of affecting the physical and mechanical properties of the matrix, the large amount of flame retardants added, and the large amount of flame retardants used and other issues, to achieve the effect of environmental protection, good flame retardancy, and halogen-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] DOPO-CH 2 Preparation of OH

[0029] Add DOPO 216g (1.0mol) and ethanol 600mL into a four-neck flask (1L) equipped with a mechanical stirrer, reflux condenser, addition funnel and thermometer, heat the reaction mixture to 70°C, and add 36 90g (1.1mol) of ~38% formaldehyde aqueous solution was added in about 30 minutes. The reactant was heated to 80° C., kept for 6 hours, cooled, filtered with suction, washed, and dried to obtain a white solid product.

[0030]

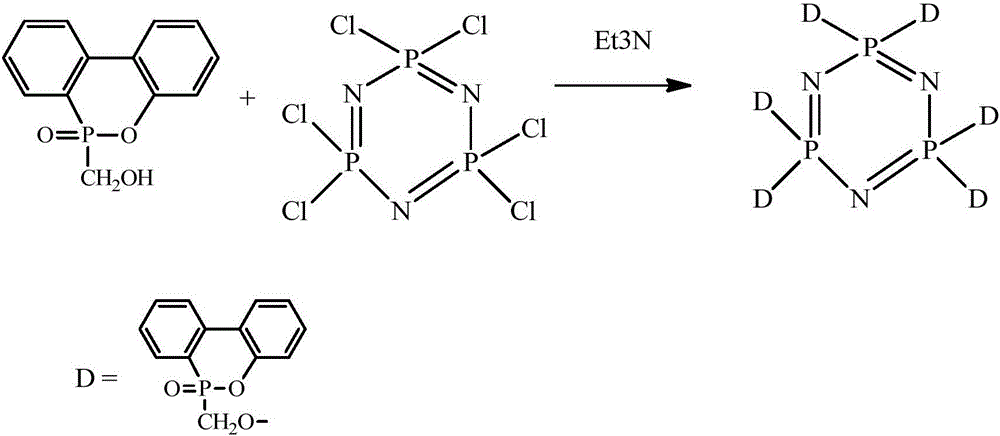

[0031] (2) Preparation of DOPO modified cyclophosphazene flame retardant (DOPO-TPN)

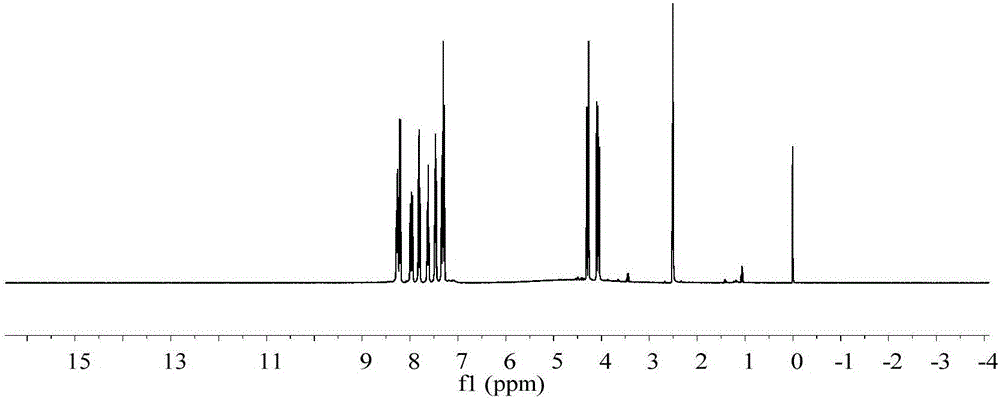

[0032] Add 100ml of chloroform into a four-necked flask (250mL) equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and then add DOPO-CH 2 14.76g (0.06mol) of OH and 3.48g (0.01mol) of hexachlorocyclotriphosphazene, and the reaction mixture was heated to reflux at 65°C. 6.06 g (0.05 mol) of triethylamine (Et3N) was added dropwise, and the addition was completed in about 1 hour, an...

Embodiment 2

[0035] (1)DOPO-CH 2 Preparation of OH

[0036] Add DOPO 216g (1.0mol) and methanol 500mL into a four-neck flask (1L) equipped with a mechanical stirrer, reflux condenser, addition funnel and thermometer, heat the reaction mixture to 70°C, and add formaldehyde dropwise under stirring 90g (1.1mol) of the aqueous solution was added in about 30 minutes. The reactant was heated to 80° C., kept for 6 hours, cooled, filtered with suction, washed, and dried to obtain a white solid product.

[0037] (2) Preparation of DOPO-TPN

[0038] Add 200ml of tetrahydrofuran into a four-neck flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and then add DOPO-CH 2 14.76g (0.06mol) of OH and 3.48g (0.01mol) of hexachlorocyclotriphosphazene, and the reaction mixture was heated to reflux at 65°C. Join K 2 CO 3 5.0g (0.036mol) was kept under reflux to continue stirring for 48h. After the reaction was finished, unreacted substances were removed b...

Embodiment 3

[0040] 5 g of DOPO-TPN prepared in Example 1 and 95 g of polyester pellets were mixed and extruded in a twin-screw extruder, and then tableted to obtain blended flame retardant polyester chips with a flame retardant content of about 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com