Elevator counterweight block and production method thereof

A production method and technology for counterweights, applied in the field of counterweights, can solve problems such as increased elevator manufacturing costs, complex casting process, and large amount of counterweights, and achieve the advantages of easy guarantee of machining accuracy, beautiful appearance, and enhanced stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

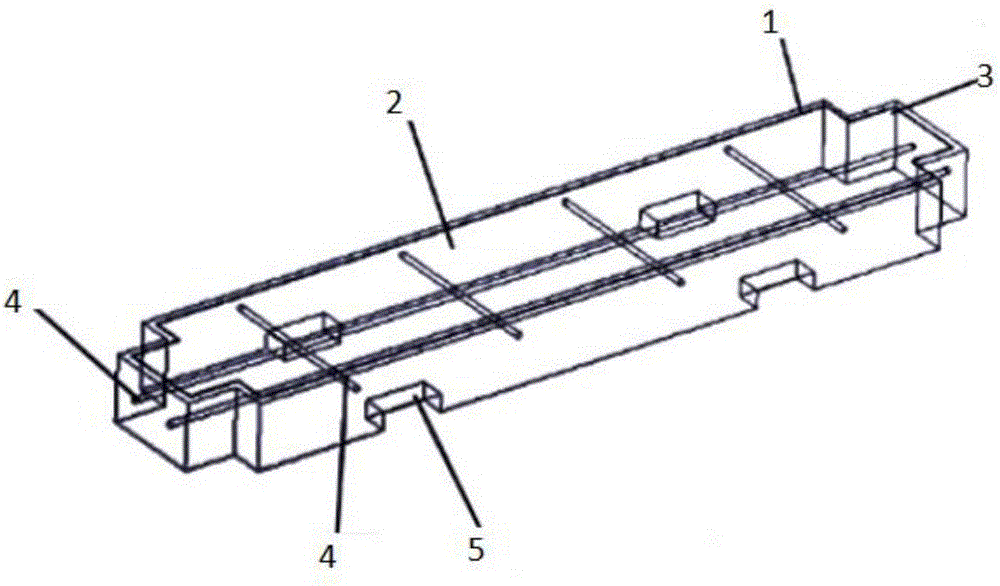

[0047] An elevator counterweight, such as figure 1 As shown, it includes a casing 1, a composite material 2 filled in the casing, a metal mesh (not shown) wrapped in the casing by the composite material, and a cover plate 3 fixedly connected to the casing;

[0048] The counterweight of the present invention is designed with four depressions 5 at the bottom outside the counterweight shell, with a size of 70×30×20. The design of the depressions is to facilitate the on-site installation personnel to carry and place the counterweight, which is reflected in the details Humanized design concept.

[0049] The composite material includes the following raw materials in parts by weight: 50 parts of cement, 150 parts of hematite ore, 3 parts of cement additive, 5 parts of binder, 5 parts of defoamer, 3 parts of anti-cracking agent, and 3 parts of water reducer , 5 parts of compacting agent, 2 parts of hardening agent, 1 part of expansion coordinating agent, 20 parts of water;

[0050]...

Embodiment 2

[0057] An elevator counterweight, comprising a shell, a composite material filled in the shell, a metal mesh wrapped in the shell by the composite material, and a cover plate fixedly connected with the shell;

[0058] The composite material includes the following raw materials in parts by weight: 80 parts of cement, 200 parts of hematite ore, 5 parts of cement additive, 10 parts of binder, 8 parts of defoamer, 5 parts of anti-cracking agent, and 5 parts of water reducer , 8 parts of compacting agent, 5 parts of hardener, 3 parts of expansion coordinating agent, 50 parts of water;

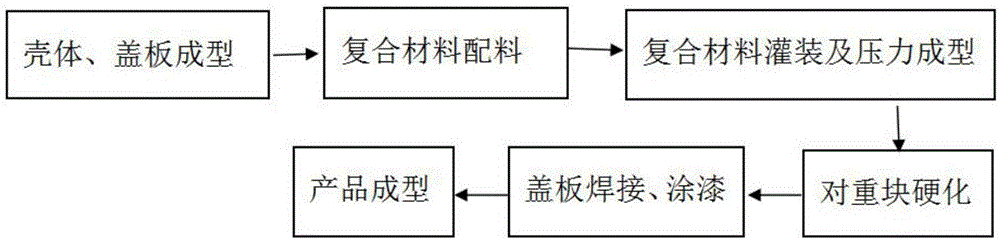

[0059] The production method of above-mentioned elevator counterweight, comprises the following steps:

[0060] Step 1. Use a steel plate with a thickness of 1mm to process a metal shell consisting of a shell and a cover plate. The upper part of the shell is open, and the cover plate matches the shell; the inner surface of the shell is uniformly concave Groove; horizontally and vertically in the sh...

Embodiment 3

[0066] An elevator counterweight, comprising a shell, a composite material filled in the shell, a metal mesh wrapped in the shell by the composite material, and a cover plate fixedly connected with the shell;

[0067] The composite material includes the following raw materials in parts by weight: 60 parts of cement, 180 parts of hematite ore, 4 parts of cement additive, 8 parts of binder, 6 parts of defoamer, 4 parts of anti-cracking agent, and 4 parts of water reducer , 6 parts of compacting agent, 4 parts of hardening agent, 2 parts of expansion coordinating agent, 40 parts of water;

[0068] The production method of above-mentioned elevator counterweight, comprises the following steps:

[0069] Step 1. Use a steel plate with a thickness of 1mm to process a metal shell consisting of a shell and a cover plate. The upper part of the shell is open, and the cover plate matches the shell; the inner surface of the shell is uniformly concave Groove; horizontally and vertically in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com