Overall cloth surface smooth and stiff shirt collar fabric

A cloth surface and rounded technology, which is applied in the field of crisp shirt collar fabrics, can solve the problems that affect the appearance of wearing, collar deformation, collar deformation, etc., and achieve the effect of easy processing, strong competitiveness, and overall tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

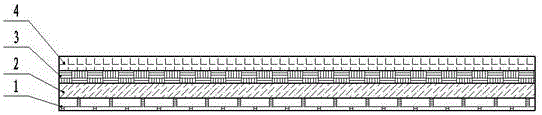

[0014] See figure 1 , An overall cloth surface is round and crisp shirt collar fabric, comprising a collar surface, the collar surface is sequentially provided with a first collar lining, a second collar lining and a lining material; the collar surface is woven with cotton fiber; The first collar lining is made of woven fabric, which is full of straight yarns. The yarn density of the knitted fabric is 28tex*28tex, using HDPE powder point fusible lining; the second collar lining is made of woven fabric, which is a net lining of diagonal silk. The yarn density of the knitted fabric is 14tex*13tex, and it is made of HDPE powder point fusible interlining; the interlining is woven with holy hemp fiber.

[0015] The back of the lining material is provided with a lining fabric layer, and the structure of the lining fabric layer is composed of seventy-one weft weaves or warp weaves from left to right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com