A semi-autogenous mill discharge device

A semi-autogenous mill and discharge device technology, applied in grain processing and other directions, can solve the problems of broken grid plate fixing bolts, prolonged downtime, insufficient rigidity, etc., to maintain stability and fluency, enrich the range of material selection, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

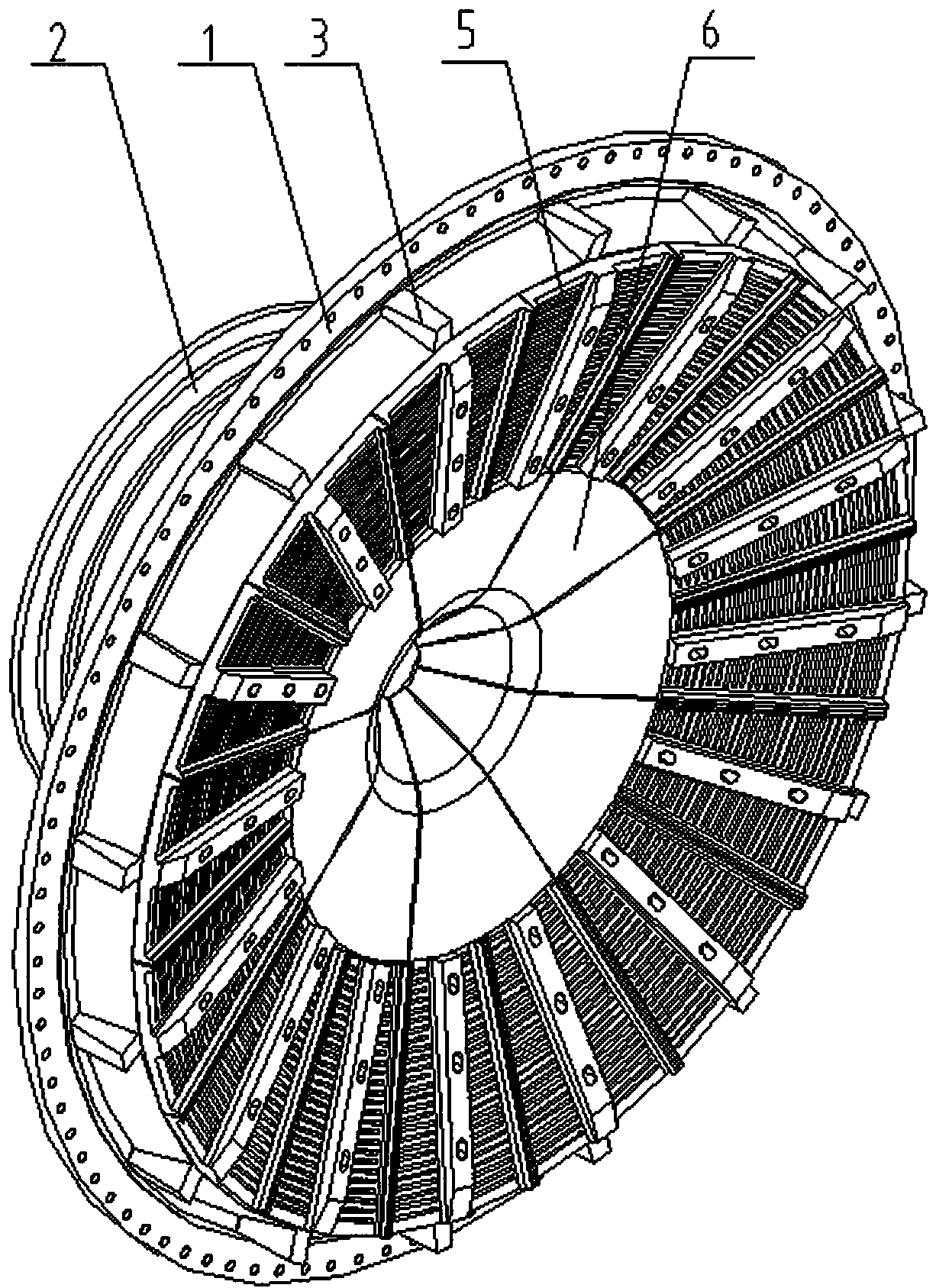

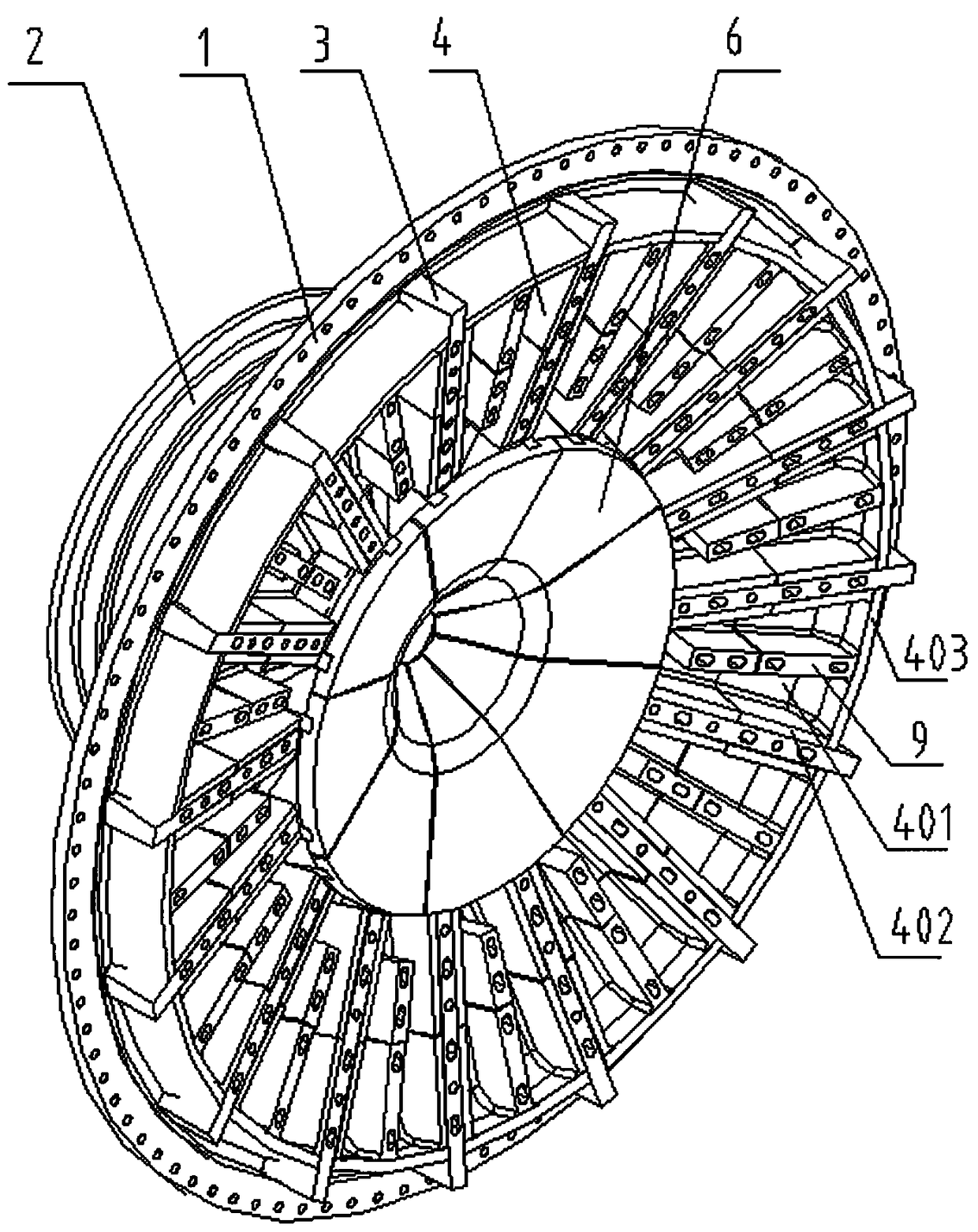

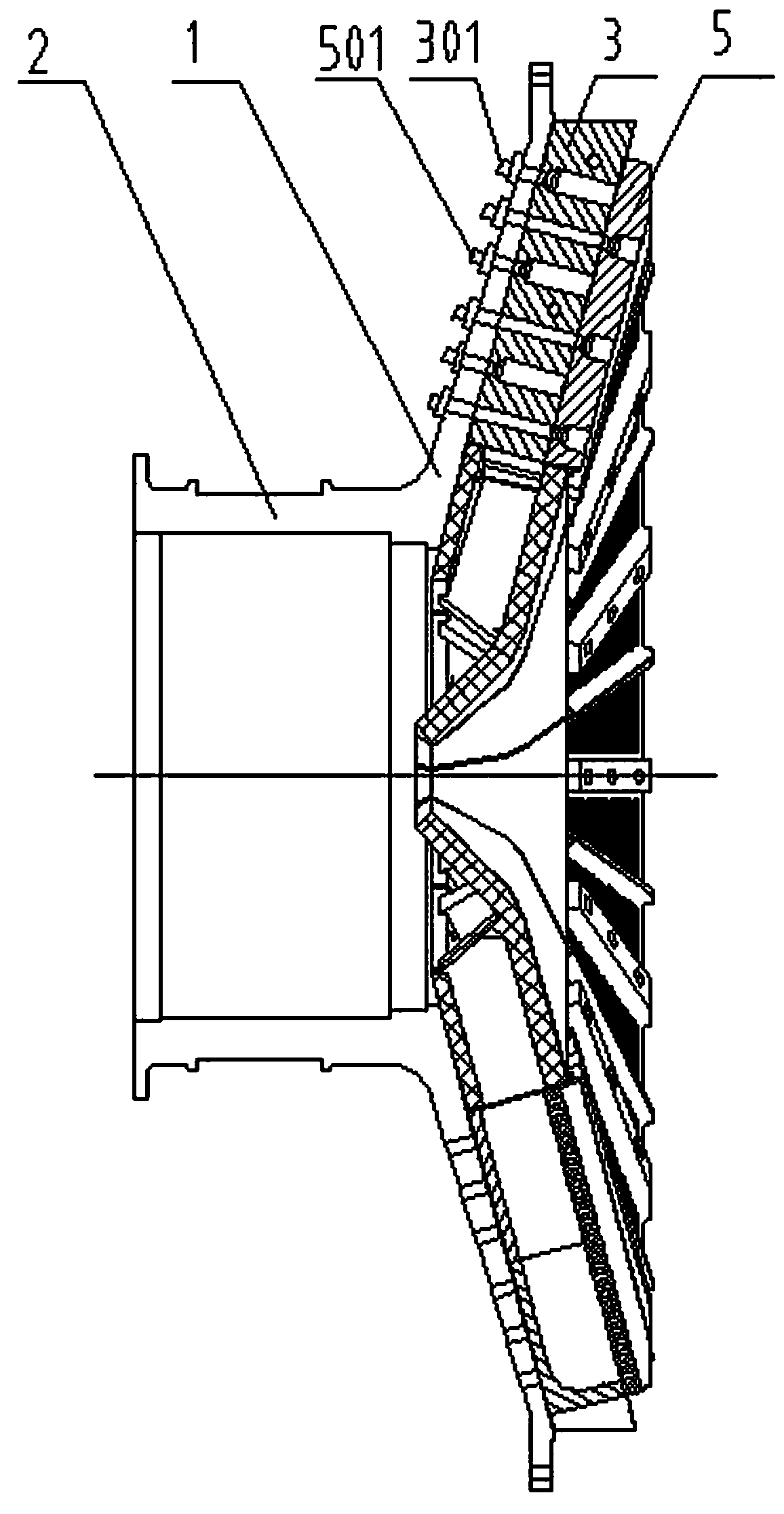

[0026] Such as figure 1 Only Figure 6 As shown, a semi-autogenous mill discharge device of the present invention includes a conical end cover 1 of the barrel of the semi-autogenous mill and a discharge pipe 2 arranged in the middle of the outer side of the end cover 1, and the inner side of the end cover 1 On the end surface of the second flat-head bolt 301, a plurality of support plates 3 for fixing the fan-shaped lattice board 5 are fixedly arranged with the center of the end cover 1 as the center and evenly spaced radially, and the second flat-head bolt 301 The nut is located on the side of the end cover 1 where the discharge pipe 2 is arranged, which is convenient for disassembly and assembly. The bolt head is arranged in the groove on the support plate 3. The selection of flat head bolts can make no gap between the support plate 3 and the fan-shaped grid plate 5. The support plate 3 is also provided with a through hole 302 and a second lifting hole 303 for installing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com