Air purification technology

An air purification and air technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of purification degree and purification efficiency defects and deficiencies, so as to reduce purification costs, improve purification efficiency, and improve treatment. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

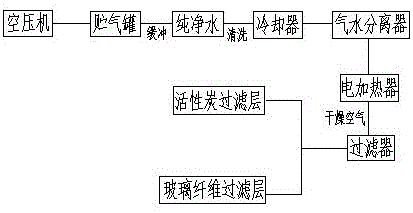

[0021] A kind of air purification process as shown in accompanying drawing, comprises air compressor, air storage tank, cooler, gas-water separator, electric heater and filter, and it specifically comprises the following steps:

[0022] (a) Let the air pass through the air compressor, compress the air and then cool it naturally;

[0023] (b) deliver the compressed air to the air storage tank;

[0024] (c) Input the compressed gas in the air storage tank into the cooler to cool the air;

[0025] (d) passing the gas through purified water;

[0026] (e) Use a gas-water separator to remove water and oil in the air;

[0027] (f) the use of electric heaters to heat the air;

[0028] (g) Pass the heated air through the filter, and finally recover the air.

[0029] The filter includes a first filter layer and a second filter layer.

[0030] The first filter layer is filled with activated carbon, and the second filter layer is provided with a glass fiber filter mesh.

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com