Three-roller medium-sized kneading machine feeding and clamping mechanism

A technology of clamping mechanism and feeding mechanism, applied in agricultural machinery and implements, agriculture, cutting equipment, etc., can solve the problems of timely adjustment, inconsistent straw length, unfavorable ruminant feeding, chewing and digestion, etc. Effective clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the specific implementation forms of the present invention are not limited to the following embodiments.

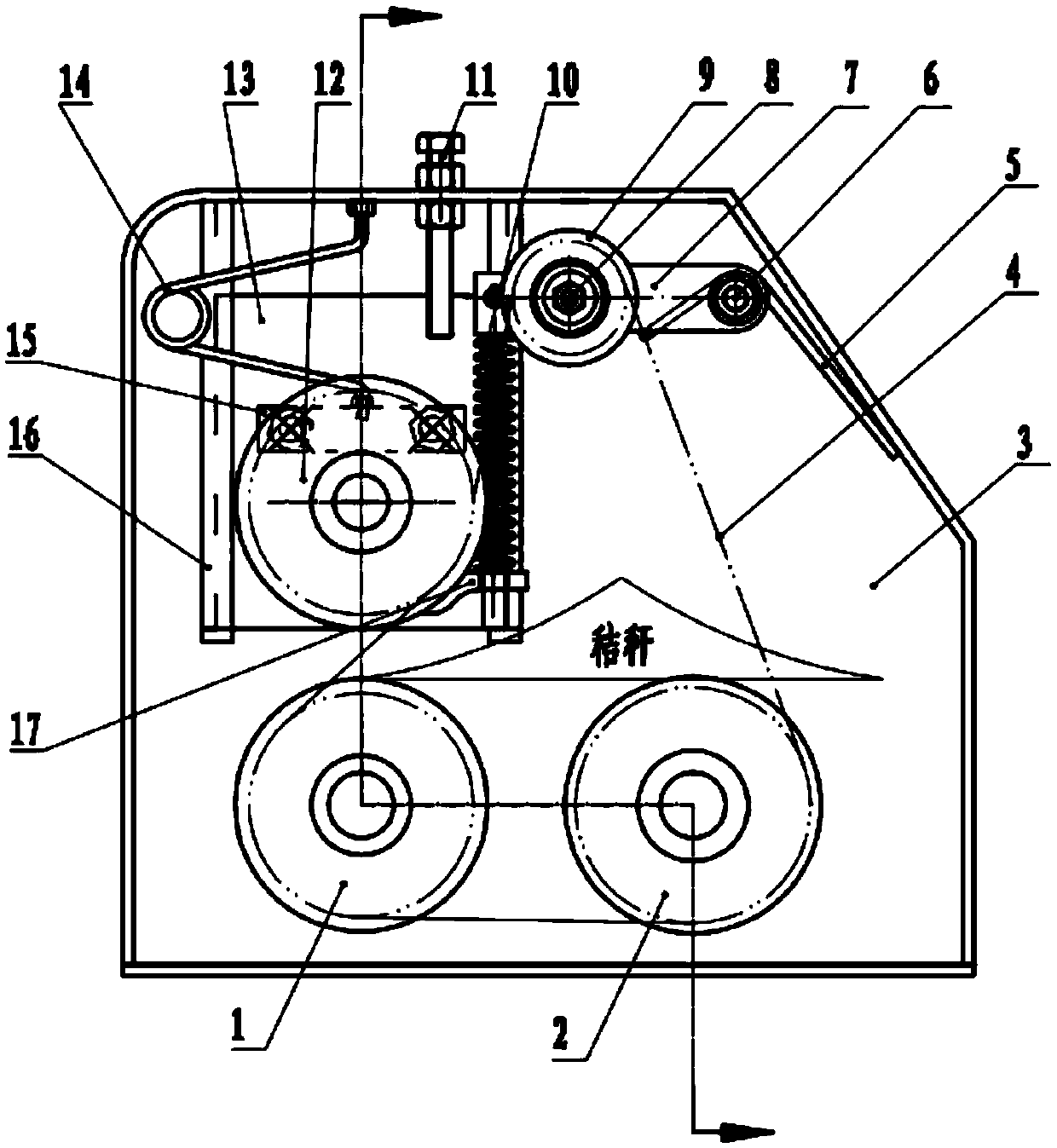

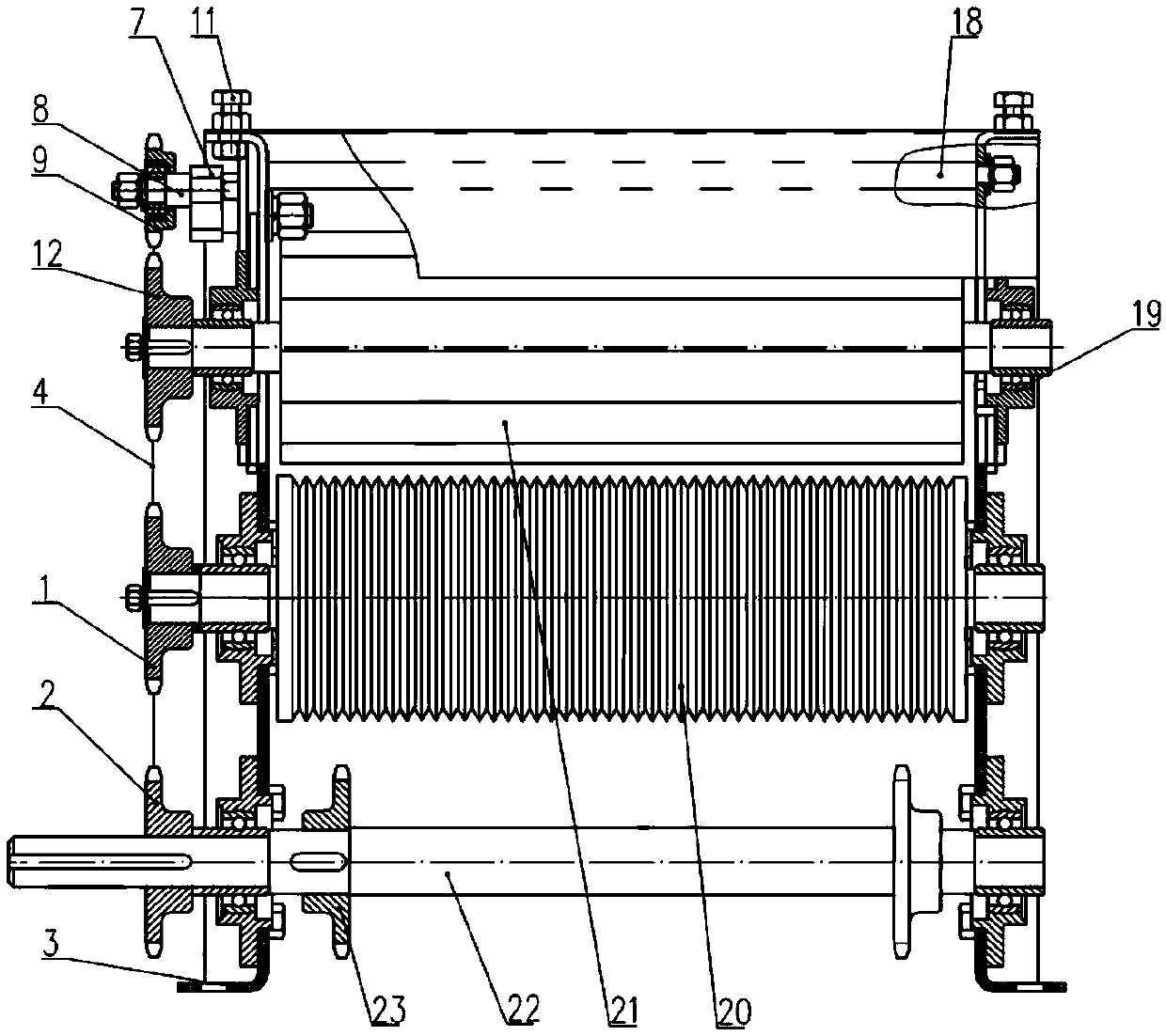

[0018] Referring to the accompanying drawings, the feeding and clamping mechanism of the three-roller medium-sized kneading machine according to the present invention consists of symmetrically arranged wallboards 3 and roller feeding mechanisms and feeding inlet elastic adjustment mechanisms arranged between the wallboards 3. composition.

[0019] The roller feeding mechanism is composed of three material rollers, the upper roller 21, the lower roller 20 and the driving sprocket shaft 22 respectively equipped with the upper sprocket 12, the lower sprocket 1 and the driving sprocket 2 on the end surface, wherein the upper roller 21 and the lower roller The feeding port of the feeding mechanism is formed between the rollers 20. The sprockets install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com