Microfluidic-based magnetic bead separation device and method

A magnetic bead separation and microfluidic technology, which is applied to measuring devices, analytical materials, instruments, etc., can solve the problems of insufficient separation of magnetic beads and easy errors, and achieve convenient enrichment, thorough adsorption, and reduced cost and labor. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

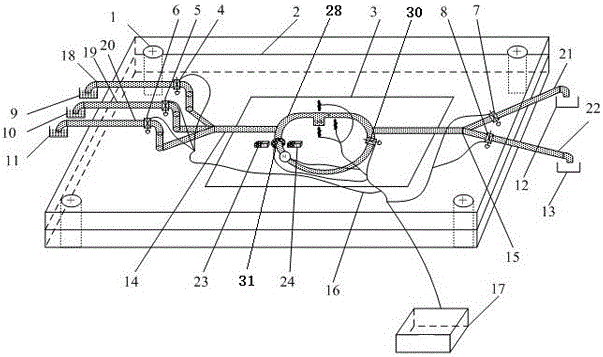

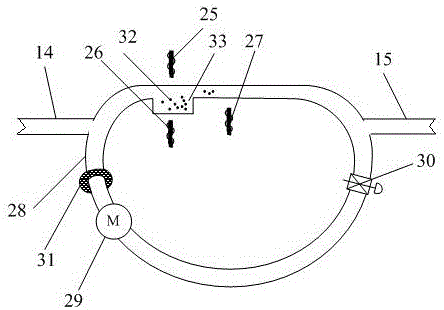

[0025] see figure 1 , The microfluidic-based magnetic bead separation device of the present invention includes a solid magnetic shielding material plate 2, the magnetic shielding material plate 2 is divided into upper and lower layers, both of which are cuboid solid magnetic shielding material plates. A group of micropipes from left to right are buried in the middle of the upper and lower layers. The main inlet pipe 14, the main outlet pipe 15 and the microfluidic chip 3 are all tightly embedded in the lower layer of the magnetic shielding material plate 2. The magnetic shielding material plate 2 The four corners of the upper and lower layers are fixed by four set screws 1, so that the upper and lower layers are tightly fixed together. The whole device has no gaps except micropipes, shielding all external magnetic interference.

[0026] The outer left side of the magnetic shielding material plate 2 is placed with three containers that respectively hold the immunomagnetic bead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com